GVWR vs Load Capacity: Understanding Vehicle Weight Limits

Explore how GVWR and load capacity differ, how to read vehicle specs, and practical steps to safely plan loads. This analytical comparison helps engineers, fleet managers, and technicians optimize weight without compromising safety.

GVWR vs Load Capacity describes two ways to measure and limit what a vehicle can carry. GVWR sets the maximum gross vehicle weight including cargo, fuel, and passengers; payload capacity is the weight left for load after subtracting curb weight. For safe operations, use both figures to size trailers, trucks, and equipment.

gvwr vs load capacity: core definitions

When engineers compare gvwr vs load capacity, the goal is to understand how weight limits influence both safety and efficiency. GVWR, the Gross Vehicle Weight Rating, is the maximum allowed weight of a vehicle in operation, counting the vehicle itself, fuel, passengers, and cargo. Payload capacity, by contrast, is the usable load that can be carried while staying within that safety ceiling. In practice, payload capacity equals GVWR minus the curb weight, and in many spec sheets it is presented as a separate figure to help planners optimize loading without violating limits. Reading documents with both numbers helps ensure that you do not underutilize capacity or push components beyond safe limits. According to Load Capacity, recognizing the interplay between gvwr vs load capacity is essential for safe vehicle loading and compliant operations.

Defining GVWR and payload capacity

GVWR is the maximum weight a vehicle should ever carry when fully loaded, including the vehicle weight, fuel, occupants, and cargo. Payload capacity is the remaining weight available for cargo and passengers after accounting for the vehicle’s own weight. The standard relationship is straightforward: payload capacity equals GVWR minus curb weight. This simple equation underpins informed decisions about what to haul, how to distribute weight, and when to consider alternative equipment. For engineers and fleet managers, focusing on both numbers helps balance safety margins with practical loading efficiency.

Curb weight, GAWR, and how they relate to loading

Two related concepts that influence gvwr vs load capacity calculations are curb weight and GAWR (Gross Axle Weight Rating). Curb weight represents the vehicle with all standard equipment but without payload or passengers. GAWR indicates the maximum weight that each axle can safely carry. When planning loads, it’s not enough to check GVWR alone; you must ensure no single axle or wheel is overloaded, and that total weight remains within GVWR. Tires, brakes, and structural components respond to the distribution of mass, so weight placement matters as much as total mass.

Reading vehicle spec sheets for safe loading

Most specs present GVWR as a key data point, alongside curb weight and occasionally payload capacity. To translate these numbers into safe practice, start with GVWR and curb weight, confirming the implied payload capacity. Look for manufacturer notes on optional equipment that can change curb weight, such as heavy-duty tires or aftermarket racks. Also, verify if the GVWR includes fuel and passengers, or if payload figures assume typical occupancy. A careful reading helps prevent surprises during inspection or on the road.

Safety, compliance, and common scenarios

Safety and regulatory compliance rely on respecting GVWR and payload relations. Overloading a vehicle can compromise braking, steering, and stability, increasing the risk of tire failure or rollover. In mixed-use fleets, you may encounter scenarios where a vehicle carries a high payload but a relatively modest curb weight, changing the effective distribution. In practice, planners should implement loading policies that keep total weight within GVWR while ensuring even distribution across axles to protect tires and suspension components.

Case studies in everyday vehicle classes

Consider a light-duty pickup used for tools and equipment: the payload capacity might be the limiting factor, even if the GVWR allows more weight overall. A passenger van, heavily loaded with occupants and cargo, may approach GVWR primarily through passenger weight rather than freight. A cargo van on a route with frequent stops benefits from a high payload capacity to maximize load management without surpassing GVWR. These examples illustrate how gvwr vs load capacity can drive different decisions depending on vehicle class and typical use.

Step-by-step calculation for safe loads

- Identify the GVWR from the vehicle specification. 2. Find curb weight, the vehicle’s own mass without payload. 3. Compute payload capacity by subtracting curb weight from GVWR. 4. Subtract expected payload (passengers and cargo) from payload capacity to determine feasible load. 5. Check distribution and ensure weight per axle remains balanced. 6. If the planned load approaches any rating, reassess equipment or consider a different vehicle or trailer.

Towing, hitch ratings, and GCWR

Towing introduces another layer: GCWR, the Gross Combined Weight Rating, which includes both the vehicle and the trailer. This metric is crucial when pairing a tow vehicle with a trailer. Always verify GCWR in addition to GVWR and tire load ratings, since misalignment among these figures increases risk. Even when payload is within GVWR, an over-towed combination can exceed GCWR and compromise braking and stability.

Misconceptions and pitfalls

A common pitfall is assuming a higher GVWR automatically means you can haul more of everything. In reality, GVWR is a safety ceiling, while payload and weight distribution dictate what you can safely carry. Another mistake is ignoring tire and axle ratings, which can become the limiting factor before GVWR is reached. Regularly reweight when configurations change, such as adding aftermarket gear or modifying seating assignments.

How Load Capacity informs practice in engineering and fleets

The Load Capacity team emphasizes that accurate weight data is essential for planning and safety. By combining GVWR knowledge with payload calculations, engineers can design safer load plans, run more efficient routes, and minimize maintenance costs. Regular audits of weight data, distributions, and equipment capabilities help ensure compliance and optimize performance.

Practical audit and maintenance checklist

- Review GVWR and payload figures on the spec sheet and confirm consistency with curb weight. - Inspect tires and suspensions for wear that could affect load capacity. - Validate load distribution across axles with measured weights. - Update loading policies whenever equipment or configurations change. - Document weight-related decisions for traceability and safety audits.

Final recommendations for engineers and fleet managers

A combined approach—using GVWR to establish safety margins and payload capacity to optimize actual loads—delivers the best balance of safety, efficiency, and compliance. Train staff to read data sheets accurately, perform regular weight audits, and maintain equipment to handle foreseeable loads. This disciplined practice reduces risk while enhancing operational effectiveness.

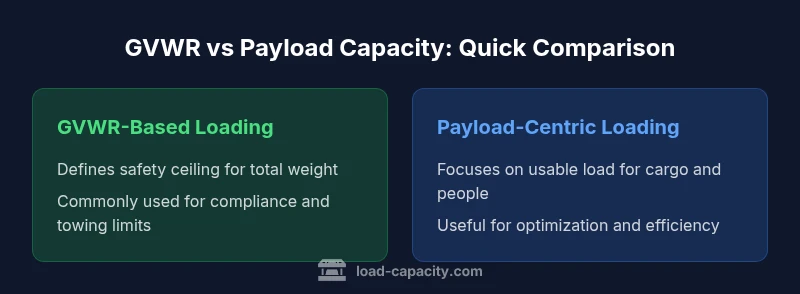

Comparison

| Feature | GVWR-based loading | Payload-based loading |

|---|---|---|

| Definition and basis | Maximum safe weight for the vehicle as a whole including cargo and occupants | Usable load after subtracting curb weight and standard options |

| Key safety implications | Ensures compliance with overall weight limits and preserves safe performance | Focuses on maximizing cargo while respecting weight constraints |

| Applications and use cases | Common for regulatory compliance and towing planning | Useful for optimization, efficiency, and load planning |

| Calculation approach | Refer to GVWR on the spec plate and ensure total mass does not exceed it | Payload equals GVWR minus curb weight, used for load planning |

Positives

- Clear safety margins that reduce overload risk

- Supports regulatory compliance and standardized policies

- Straightforward to apply across fleets and equipment

- Simplifies insurance and inspection processes

Cons

- May underutilize capacity in certain mixed-use scenarios

- Can be overly conservative for dynamic or multi-use operations

- Requires regular reweighting if configurations change or accessories are added

Hybrid approach wins: combine GVWR safety margins with payload-based loading to optimize capacity without compromising safety

GVWR ensures compliance and safety, while payload calculations unlock real-world loading efficiency. Use both together for best practice in engineering and fleet management.

Quick Answers

What is GVWR and how does it differ from payload capacity?

GVWR is the maximum weight the vehicle can safely carry in total, including the vehicle itself, fuel, passengers, and cargo. Payload capacity is what remains available for cargo and occupants after accounting for the vehicle’s own weight. Understanding both helps prevent overloading and underutilization.

GVWR sets the safety ceiling, while payload capacity tells you how much you can actually load. Use both to plan loads accurately.

Why is GVWR important for safety and regulations?

GVWR is a regulatory and safety parameter used to prevent vehicles from carrying unsafely heavy loads. Exceeding GVWR can impair braking, handling, and tire life, increasing the risk of accidents and fines.

Exceeding GVWR can be unsafe and may violate regulations, so it’s essential to stay within limits.

How do you calculate payload capacity?

Payload capacity is calculated by subtracting the curb weight from the GVWR. This figure represents the maximum weight available for cargo and passengers.

Payload is GVWR minus curb weight, the load you can safely carry.

Can you exceed GVWR if your payload is within capacity?

No. GVWR is a ceiling for total mass. Even when payload is within capacity, other factors like axle ratings and tire limits can constrain what you can carry.

No, GVWR is a safety ceiling and other limits still apply.

How do tire and axle ratings interact with GVWR?

Tire load ratings and axle ratings can cap safe loads before GVWR is reached. Always verify these ratings; a higher GVWR does not automatically mean higher safe loads if tires or axles limit capacity.

Tires and axles can limit loads earlier than the GVWR, so check those ratings too.

What is GCWR and when does it matter?

GCWR stands for Gross Combined Weight Rating and matters when towing a trailer. It represents the maximum allowable weight of the towing vehicle plus the trailer and load, and it can govern combined loading decisions.

GCWR controls the total combined weight when towing; keep it in mind during planning.

Top Takeaways

- Check GVWR and curb weight before planning loads

- Calculate payload capacity as GVWR minus curb weight

- Distribute weight to protect tires and axles

- Reweight and adjust when configurations change

- Use GCWR considerations for towing scenarios