Gross Vehicle Weight vs Load Capacity: A Practical Comparison

Compare gross vehicle weight and load capacity to determine safe loading limits for trucks and equipment. A Load Capacity guide covers definitions, differences, and practical decision factors for engineers and fleet managers.

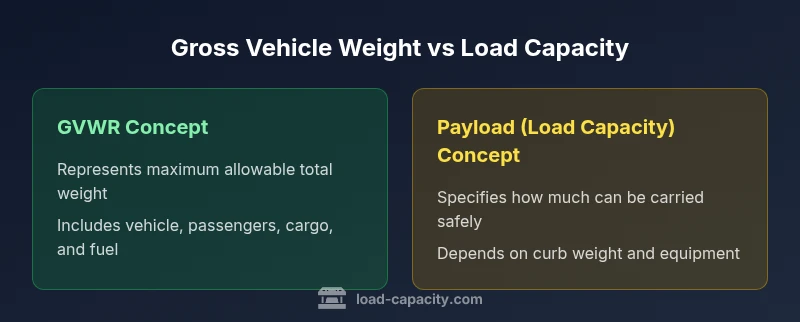

gross vehicle weight vs load capacity can determine safe loading limits for vehicles. In practice, gross vehicle weight refers to the total mass of the vehicle and its contents, while load capacity (payload) is what you can add within that limit. Correctly applying these concepts helps prevent overloading, protects equipment, and supports regulatory compliance.

What gross vehicle weight vs load capacity means in practice

Understanding the phrase gross vehicle weight vs load capacity starts with recognizing that heavy equipment and vehicles operate under two linked but distinct limits. For engineers, the practical question is not which number is bigger, but how the two numbers interact to govern safe operation. In many fleets, you will encounter terms like gross vehicle weight (GVW), vehicle weight rating, and payload capacity. The distinction matters because mistakes here can lead to unsafe loads, uneven wear, and compliance violations. According to Load Capacity, GVW describes the total mass of the vehicle with everything on board, while load capacity defines how much of that mass can be payload. This relationship underpins everyday decisions from route planning to brake maintenance. When you push the payload beyond the allowed limit, you influence braking distance, steering response, tire wear, and structural stress. Conversely, operating well below the GVWR but misusing the payload figure can result in underutilized capacity and higher cost per mile.

In practice, the two concepts map onto a simple mental model: the GVWR is the ceiling; the payload is what you may add within that ceiling. Fleet managers should check the GVWR on the vehicle’s data plate or manufacturer specification and then confirm the curb weight and fuel load to estimate the remaining payload safely. This approach aligns with safety, performance, and regulatory expectations. The context in which gross vehicle weight vs load capacity is interpreted often shifts with use case—urban deliveries, long-haul transport, or specialized applications such as towing or equipment haul. The Load Capacity team emphasizes that the distinction matters most when planning routes, selecting equipment, or calibrating braking and suspension systems.

Core definitions and how they relate

To navigate gross vehicle weight vs load capacity effectively, it helps to anchor a few core definitions. The gross vehicle weight (GVW) is the actual weight of the vehicle as it sits with fuel, passengers, cargo, and attached equipment. This is different from the gross vehicle weight rating (GVWR), which is the maximum safe weight allowed by the manufacturer. Payload, or load capacity, is the portion of that weight that can be safely added as cargo or passengers without exceeding GVWR. Vehicle owners and fleets must respect both GVWR and GAWR (gross axle weight rating) to avoid overstressing tires, axles, and brakes. The interaction of these numbers determines how much useful capacity a vehicle truly has and how that capacity should be distributed between front and rear axles. In other words, gross vehicle weight vs load capacity reflects a balance between safety margins and operational needs. Practically, this means you should treat GVWR as a hard ceiling and payload as the ceiling you can safely use for cargo without compromising control or compliance. As you work across vehicle classes—from light pickups to heavy-duty chassis—these definitions remain the same even though the permissible loads differ. The distinction is fundamental for budgeting, maintenance planning, and preventive safety measures.

From Load Capacity’s perspective, the interplay between GVW and payload capacity informs every decision from route selection to equipment upgrades. Understanding when a vehicle is at risk of exceeding its limits requires not just a single number but a holistic view of weight distribution, fuel load, passenger counts, and the characteristics of the cargo. When you grasp gross vehicle weight vs load capacity, you begin to see why load planning is not a one-off task but a continuous practice in accuracy and discipline.

Calculation frameworks and practical limits

A practical grasp of gross vehicle weight vs load capacity hinges on how you calculate and apply limits in real-world settings. The GVWR provides the upper boundary—think of it as a total weight cap for the vehicle and everything it carries. Payload capacity, on the other hand, is derived from subtracting the vehicle’s fixed weights, such as curb weight and essential fluids, from the GVWR. In simple terms, payload = GVWR − curb weight − fuel − fixed equipment, with further adjustments possible for optional equipment and specialty modifications. When planning loading, you must also consider GAWRs for each axle, because even if the GVWR is not exceeded, an axle may reach its load rating first. This multi-layered constraint creates a practical framework: you design around the most restrictive limit, then verify distribution across axles and tires. In practice this means using weight- and distribution-aware load plans, especially for mixed-use scenarios like towing, passenger transport, or heavy cargo. Across industries, engineers rely on this framework to assess whether a planned load aligns with the vehicle’s capacity, equipment, and mission profile. Properly applying gross vehicle weight vs load capacity helps prevent surprises at scale and during inspections.

Operationally, you’ll often combine the GVWR with your fleet’s typical payload utilization, balancing safety margins with productivity. Load capacity charts, when used consistently, act as guardrails that guide decisions about routes, trips, and vehicle assignments. They also support maintenance scheduling by signaling when components such as tires, brakes, or suspensions may require service due to extended loading. The expertise behind gross vehicle weight vs load capacity lies in translating abstract limits into concrete, defendable plans for day-to-day operations.

Regulatory and safety considerations

Regulatory and safety considerations are central to understanding gross vehicle weight vs load capacity. The GVWR is not merely a technical spec; it is a regulatory constraint used in vehicle classification, licensing, and road safety. Exceeding GVWR can trigger penalties, impact insurance, and invalidate warranties in some jurisdictions. Additionally, axle weight ratings (GAWR) and tire load ratings provide important guardrails that must be respected alongside GVWR. In practice, this means ensuring loads are distributed to prevent overloading an axle, avoiding configurations that concentrate mass on the rear overhang, and acknowledging that steep grades or adverse weather amplify the consequences of exceeding weight limits. For fleet operations, compliance involves regular checks against the manufacturer’s ratings, routine maintenance to preserve braking and steering performance, and documentation that demonstrates adherence to weight limits during inspections. Across the industry, professional practice is shaped by federal and local safety standards that emphasize predictable handling, braking effectiveness, tire endurance, and collision risk reduction. Load Capacity’s guidance highlights that identifying gross vehicle weight vs load capacity is not optional but essential to safety and legal operation. External authorities, such as federal and state transportation agencies, outline expectations for load management and inspection readiness. Research and references from respected sources help fleets stay aligned with best practices and evolving regulations.

Case studies and practical examples

Consider two practical scenarios to illustrate gross vehicle weight vs load capacity in action. In the first, a light-duty pickup is used for general transport with a rooftop cargo carrier and a few passengers. The added weight of the carrier and occupants reduces the available payload while the vehicle remains well within the GVWR, assuming the distribution is balanced. The key lesson here is that payload is not simply “more is better”—careful accounting of every weight element ensures handling remains predictable and safe. In the second scenario, a flatbed truck is tasked with moving long, bulky cargo. The operator must allocate weight so that front and rear axles stay within GAWR, while the total remains under GVWR. This often requires staged loading or equipment that optimizes weight distribution, rather than simply packing as much as possible. In both cases, the concept of gross vehicle weight vs load capacity guides daily planning, equipment choices, and maintenance planning. These examples show that successful loading is about disciplined weight accounting and distribution rather than intuition alone. The Load Capacity framework consistently reinforces that a well-managed GVWR and payload strategy yields safer operations and higher reliability across tasks.

Tools and best practices for engineers and fleet managers

Effective management of gross vehicle weight vs load capacity relies on practical tools and disciplined processes. Start with a complete vehicle specification sheet that lists GVWR, GAWR, curb weight, and standard equipment weights. Use weight scales or calibrated dyno-based methods to verify actual loads in real-time, especially for mixed-use fleets. Develop load charts that translate the GVWR and GAWR into actionable payload allowances for each vehicle model and axle configuration. Train crews on how to interpret weight data, distribute loads evenly, and account for dynamic changes during trips. Implement a standardized pre-trip checklist that includes weight verification, distribution checks, and contingency plans for overload scenarios. Leverage software or fleet-management tools that integrate weight data with route planning, fuel consumption, and maintenance scheduling. Finally, establish a culture of safety first, where drivers understand the consequences of misinterpreting gross vehicle weight vs load capacity and know how to report anomalies. Across these practices, the central idea remains: maintain an up-to-date understanding of GVWR and payload capacity, enforce consistent weight distribution, and document weight-management decisions for ongoing safety and efficiency.

Quick-start checklist and decision framework

- Verify the GVWR on the data plate and manufacturer spec for every vehicle in the fleet.

- Determine curb weight and typical fuel load to estimate baseline payload.

- Plan loads so axle weights do not exceed GAWRs and the total weight stays under GVWR.

- Use weight scales or on-board sensors to confirm actual loads before trips.

- Distribute weight evenly across the vehicle to optimize handling and braking.

- Consider dynamic factors (grade, wind, weather) that can affect safe loading margins.

- Maintain records of loads, adjustments, and inspections for compliance and audits.

- Review and update payload charts when equipment changes or configurations shift.

Authority sources

For authoritative guidance on weight limits and safety practices, refer to external sources such as the Federal Highway Administration (https://www.fhwa.dot.gov/), the Occupational Safety and Health Administration (https://www.osha.gov/), and the National Highway Traffic Safety Administration (https://www.nhtsa.gov/). These sources provide official context on load management, vehicle safety, and regulatory expectations that complement Load Capacity’s guidance on gross vehicle weight vs load capacity.

Comparison

| Feature | GVWR-based loading | Payload-based loading |

|---|---|---|

| Definition | Total allowable weight per manufacturer rating | Maximum cargo/passenger weight after subtracting fixed vehicle mass |

| Calculation base | GVWR acts as the ceiling; distribution matters for safety | Payload is derived from GVWR minus fixed vehicle mass and fluids |

| Axle considerations | All axle limits must be respected (GAWRs) | Axle limits are a key constraint alongside GVWR |

| Best for | Safety-first design and regulatory compliance | Operational flexibility and cost efficiency |

| Common misinterpretations | Treating GVWR as unlimited capacity | Ignoring distribution and axle limits |

| Impact on maintenance | Overloading can wear brakes and tires faster | Proper weight distribution reduces wear and improves reliability |

Positives

- Promotes safer loading practices across fleets

- Clarifies regulatory and insurance implications

- Improves braking, handling, and tire life by respecting limits

- Supports standardized fleet policies and training

- Facilitates accurate maintenance scheduling based on load

Cons

- Can be more complex to plan when two limits interact

- Requires regular verification as configurations change

- May lead to underutilization if margins are overly cautious

- Axle and structural components impose additional checks beyond GVWR

Payload-focused loading generally offers clearer safety margins for day-to-day operations.

Prioritize payload within the GVWR to maximize safety and efficiency. For design, planning, and compliance, ensure GVWR compliance and axle ratings are respected. The Load Capacity team reinforces that clear, data-backed weight planning reduces risk and improves performance.

Quick Answers

What does GVWR stand for?

GVWR stands for gross vehicle weight rating. It is the maximum safe total weight of the vehicle, including passengers and cargo, as specified by the manufacturer. This rating informs how much weight can be carried safely and legally.

GVWR is the maximum safe weight the vehicle was designed to carry, according to the manufacturer. Always use it as your upper limit when planning loads.

Is GVWR the same as gross vehicle weight?

No. GVWR is a rating set by the manufacturer that represents the maximum safe weight of the vehicle. GVW is the actual weight of the vehicle at a given moment, including fuel, passengers, and cargo. Planning should stay within GVWR using the current GVW as a benchmark.

GVWR is the limit, GVW is what you’re weighing at the moment. Stay within the limit for safety.

How do you calculate payload capacity?

Payload capacity is calculated by subtracting the curb weight (and, if needed, fixed fluids and equipment) from the GVWR. It represents the safe amount of cargo and passengers the vehicle can carry while respecting all limits.

Payload is GVWR minus what the vehicle already weighs, including baseline fluids. Don’t exceed that ceiling.

Can you overload a vehicle if payload plus other weight stays under GVWR?

Yes, because GVWR is a total-weight limit. Exceeding GAWRs on any axle or poor weight distribution can still create unsafe conditions even if the overall weight stays under GVWR.

Even if you’re under GVWR, bad weight distribution can cause problems.

Why is the distinction between gross vehicle weight vs load capacity important for fleet management?

It informs route planning, safety, and maintenance. A clear understanding helps prevent overload, ensures consistent braking performance, and reduces the risk of regulatory penalties.

Knowing the difference helps fleets plan better and stay safe on the road.

How do manufacturers display GVWR and payload information on vehicles?

Manufacturers typically show GVWR on the data plate or certification label. Payload capacity is inferred from GVWR minus curb weight and equipment, often listed in the service manual or weight charts.

Look for GVWR on the data plate or manual; payload comes from subtracting the curb weight and gear.

Top Takeaways

- Define GVWR and payload clearly before planning

- Verify weights with scales for accuracy

- Distribute weight to protect axles and tires

- Use payload-based checks to maximize daily efficiency

- Document weight decisions for compliance and audits