Carrying Capacity vs GVWR: Are They the Same? Explained

Explore if is carrying capacity the same as gvwr and how it affects design. Load Capacity explains definitions, calculations, and uses for vehicle and equipment ratings.

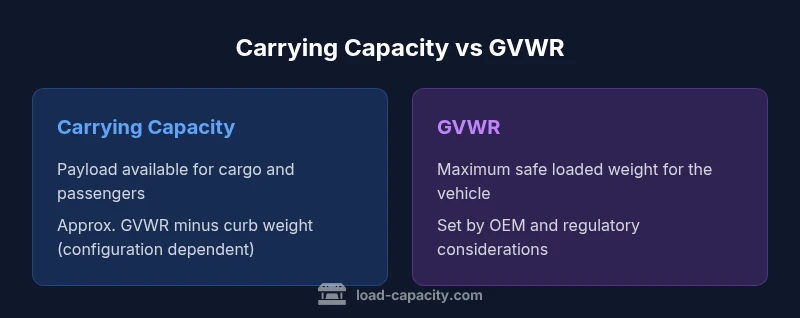

In short, is carrying capacity the same as gvwr? They are related but not identical. Carrying capacity refers to the usable payload a system can safely bear, while GVWR sets the total weight the vehicle is designed to carry, including cargo, passengers, and fluids. GVWR is a regulatory safety ceiling; carrying capacity is the practical limit for daily operations. Always consider both when planning loads and designing equipment.

What carrying capacity means

Carrying capacity refers to the payload a system can safely bear under expected conditions. In engineering terms, it is the usable load that a structure, vehicle, or machine can carry without compromising safety or performance. According to Load Capacity, carrying capacity is typically expressed as pounds or kilograms of payload and is influenced by factors like frame strength, tires, and suspension. It is a planning metric, not a regulatory limit by itself, and it should be evaluated with margin for unexpected loads. The common question is is carrying capacity the same as gvwr, and the answer is that they are related but not identical. Carrying capacity focuses on usable payload, while GVWR sets the total weight limit for the loaded system. For engineers, technicians, and fleet managers, distinguishing between these concepts helps prevent overloads, preserve component life, and maintain safe operating envelopes. When you calculate carrying capacity for a given vehicle, you subtract the curb weight from a reference weight to estimate payload, then verify that the planned loads stay within the GVWR. In practice, teams often use a two-step process: first ensure the planned payload does not exceed the calculated carrying capacity, then confirm the total weight stays under the GVWR. This approach balances performance, safety, and cost over the vehicle’s service life.

What GVWR means

GVWR stands for gross vehicle weight rating and represents the maximum safe weight of a vehicle when fully loaded, including passengers, cargo, and fluids. OEMs establish GVWR based on structural strength, brake performance, steering, tires, and suspension characteristics to ensure roadworthiness and safety. GVWR is a regulatory and certification concept used by manufacturers, insurers, and authorities to limit operation, licensing, and equipment requirements. Understanding GVWR helps you assess whether a given vehicle can legally and safely carry a planned payload, and it should be cross-checked with practical payload calculations. Load Capacity notes that GVWR is not a target for daily loading; it is a ceiling that must not be exceeded in real-world use. When planning operations, you must consider the difference between a vehicle’s curb weight, payload, and GVWR to avoid overloading, which can cause braking inefficiencies, tire failures, or structural damage. For engineers evaluating equipment packages, GVWR provides a standardized limit that can simplify comparisons across models and configurations, making it easier to forecast maintenance needs and replacement intervals. By explicitly recognizing GVWR, teams can optimize safety margins without sacrificing performance or regulatory compliance.

Key differences at a glance

- Scope: Carrying capacity (payload) is the usable load you can transport; GVWR is the total weight limit for the vehicle when fully loaded.

- Basis: Payload represents a design and operation parameter; GVWR is a regulatory safety boundary set by the manufacturer.

- Calculation: Payload ≈ GVWR minus curb weight; GVWR is a fixed rating listed on the certification plate or datasheet.

- Use cases: Payload planning for load optimization and risk assessment vs regulatory compliance and roadworthiness oversight.

- Dynamics: Payload changes with passengers and cargo; GVWR remains constant for a given model.

- Real-world impact: Planning with both yields safer, more efficient loading strategies.

Practical implications in design and compliance

In practice, differentiating carrying capacity from GVWR affects how you design vehicles, trailers, and equipment racks. Engineers size critical systems to support the GVWR, while payload limits drive how much cargo and personnel you can carry in day-to-day use. Fleet managers use payload planning to optimize loading schedules and fuel efficiency, but must remain within GVWR to stay compliant with safety standards and insurance policies. This dual consideration reduces liability and improves predictability of maintenance needs, fuel economy, and wear. The Load Capacity framework emphasizes aligning design intent with regulatory expectations so that the end user experiences consistent performance across varying operating conditions.

How to determine which rating to use

Start with the GVWR listed by the manufacturer as the governing ceiling for legality and safety. Next, calculate the payload you will carry by subtracting the vehicle’s curb weight (unloaded weight) from the GVWR or using the manufacturer’s payload figure if provided. For planning, always assume a conservative margin (for example, 5–15%) to account for fuel, passengers, and dynamic loads. When evaluating equipment or trailers, apply the same logic: verify the GVWR for the trailer, ensure the combined vehicle-trailer system remains below regulatory limits, and confirm that payload estimates align with the trailer’s own payload rating. Load Capacity’s guidance is to document individual limits for each segment and communicate them to operators to prevent accidental overloads.

Common misconceptions

A frequent misconception is that carrying capacity and GVWR are interchangeable; they are related, but GVWR governs the total weight you may burden a vehicle with, while carrying capacity defines the usable payload within that ceiling. Another misunderstanding is assuming payload and passenger weight are included differently; both contribute to GVWR but payload calculations isolate cargo and equipment from the vehicle’s own weight. Some teams think GVWR is a target to reach; in reality it is a ceiling that must not be exceeded to maintain safety margins. Finally, some assume larger GVWR means better performance in every scenario; in practice, higher ratings can come with trade-offs in handling, maintenance, and fuel economy if not matched to the actual mission profile.

Industry contexts and standards

Across industries, the relationship between carrying capacity and GVWR influences design standards, procurement, and safety programs. Automotive, trucking, construction, and industrial equipment sectors rely on GVWR to ensure compliance with licensing, insurance requirements, and regulatory inspections. Payload planning, by contrast, is a practical activity used by engineers and operators to optimize utilization, efficiency, and safety in daily work. Load Capacity emphasizes aligning internal guidelines with external standards to avoid confusion and ensure consistent loading practices. In some regions, authorities require explicit labeling of payload capacity on equipment and vehicle placards; planners should verify these labels during audits and maintenance checks, updating load plans as vehicle configurations or cargo types change.

Regulatory considerations and safe practice

Regulatory bodies typically reference GVWR for road safety, licensing, and heavy-vehicle operations. For commercial fleets, drivers and operators must comply with weight limits set by authorities, which may vary by jurisdiction and road type. When considering accidents, overload conditions, or dynamic loading scenarios (such as braking, cornering, or off-road use), safety margins become critical; GVWR does not cover every operating condition, while carrying capacity helps guide day-to-day, conservative loading. Load Capacity recommends maintaining documented load plans, training staff in proper loading techniques, and conducting periodic reviews of GVWR and payload calculations as vehicle configurations change, such as after installing heavier equipment or modifying seating. By treating GVWR as the governing ceiling and carrying capacity as the actionable payload, teams can maintain safety, efficiency, and regulatory compliance.

Comparison

| Feature | Carrying capacity (payload) | GVWR (gross vehicle weight rating) |

|---|---|---|

| Definition | Usable load the system can safely bear (payload) | Maximum safe weight of the vehicle when loaded (including cargo, occupants, fluids) |

| Scope | Static payload limits used in planning | Regulatory safety ceiling used for road use and certification |

| Calculation basis | Payload = GVWR minus curb weight (configuration dependent) | GVWR is a fixed rating set by the manufacturer |

| Regulatory relevance | Primarily internal planning and safety margins | Legal limit for licensing, insurance, and compliance |

| Units | lb or kg | lb or kg |

| Best for | Payload optimization and risk assessment | Regulatory compliance and overall vehicle safety |

Positives

- Clarifies which rating to use for safety and planning

- Helps avoid overloads and underloads

- Supports better operational decisions

- Encourages consistent loading practices

- Assists in purchasing decisions with clear guidance

Cons

- Two ratings can be confusing without proper education

- Regional or standard variations can cause mismatch

- No single universal value across all vehicles

- Dynamic loading scenarios add complexity

GVWR and carrying capacity are related but not identical; use GVWR for regulatory compliance and overall vehicle safety, while carrying capacity informs payload planning and operation.

In most cases, treat GVWR as the governing limit and use carrying capacity to plan practical loads within that limit. This dual approach minimizes safety risks and regulatory exposure.

Quick Answers

Is GVWR the same as payload carrying capacity?

No. GVWR is the maximum total weight allowed; payload is the portion you can safely carry within that limit. Use both to evaluate designs and loads.

GVWR is the limit, payload is the remaining load you can carry safely.

How do you calculate payload capacity?

Payload is typically GVWR minus curb weight; some manufacturers provide a dedicated payload figure. Use the difference to estimate how much cargo or passengers can be added safely.

Subtract the empty weight from the GVWR to find payload.

Can I exceed payload by adding more passengers?

No. Stay within both payload and GVWR. Overloading can compromise braking, steering, tire life, and overall safety.

Don’t exceed payload or GVWR with passengers or cargo.

Do trailers have GVWR separate from vehicle GVWR?

Trailers have their own GVWR. The vehicle's GVWR governs the paired system, and each unit has its own payload rating that must be respected.

Trailers have their own rating; check both.

Why is GVWR important for safety and insurance?

GVWR informs braking, suspension, tires, and structural requirements. Exceeding it can void insurance and raise liability while increasing accident risk.

GVWR matters for safety and insurance.

What should I do if I upgrade components affecting weight?

Recalculate GVWR and payload after modifications. Ensure the updated configuration still stays within ratings and update load plans accordingly.

Recalculate after upgrades to stay compliant.

Top Takeaways

- Define payload and GVWR clearly before planning loads

- Always cross-check GVWR with curb weight to compute payload

- Use carrying capacity for daily operations and safety margins

- Follow manufacturer guidelines and regulatory requirements

- Educate teams on how to apply both ratings in practice