Tare Weight vs Load Capacity: Definitions, Differences, and Practical Guidance

A rigorous comparison of tare weight vs load capacity, with clear definitions, practical calculations, and best-practice guidance for engineers, fleet managers, and DIY enthusiasts.

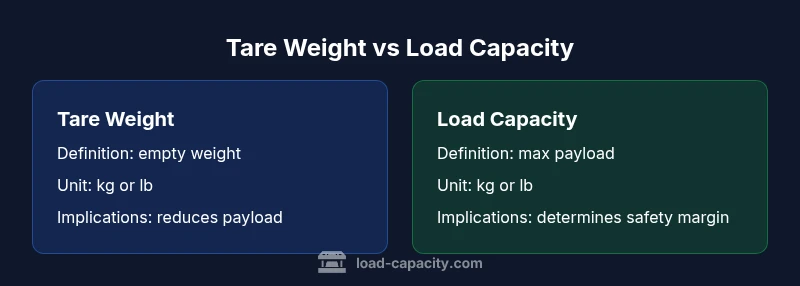

Tare weight is the weight of an empty vehicle or container, while load capacity is the maximum payload it can safely carry. These two values are linked by the gross vehicle weight rating (GVWR) and the gross combination weight rating (GCWR). In practice, you determine payload by subtracting the tare weight from the GVWR; staying within this limit is essential for safety and compliance. This quick view sets up the deeper distinctions discussed below.

Understanding the Core Terms

Tare weight vs load capacity are fundamental for any engineering, fleet, or DIY calculation. According to Load Capacity, tare weight represents the weight of a vehicle or container when it is empty of payload, fluids, and occupants. Load capacity, by contrast, denotes the maximum payload the vehicle can carry without exceeding safety limits such as GVWR or axle ratings. The distinction matters for planning, budgeting, and safety, and it underpins how you assess whether a given load is appropriate for the vehicle in question. In practice, most teams think in terms of how much mass can be added before hitting the legal weight ceiling, bounded by the tare light weight and the vehicle’s weight-rating boundaries. This distinction is also essential for intermodal operations, where multiple modes of transport must respect weight limits at each transfer point.

Distinctions That Drive Design and Planning

The practical difference between tare weight and load capacity drives every design decision, from selecting a chassis to choosing suspension systems and load distribution strategies. When you compare tare weight vs load capacity, you’re comparing empty mass against usable mass for transport. Engineers use these figures to forecast driveability, braking performance, and fuel efficiency. Fleet managers rely on them for payload optimization, route planning, and compliance with road-safety laws. The most important takeaway is that a higher tare weight reduces available payload if GVWR remains fixed, underscoring why light-weight materials and optimized componentry can extend usable capacity without compromising safety.

How Tare Weight is Measured

Tare weight is typically measured with the vehicle or container empty, including standard fluids if applicable, but excluding payload. It can be obtained from manufacturer specifications, certification documents, or calibrated weighing like a dedicated scale. For custom builds, repeatable tare measurements are critical because even small changes (extra equipment, fuel level, or ballast) shift payload capacity. Regularly reassessing tare weight ensures you don’t overestimate load capacity or misinterpret the remaining margin to GVWR. The accuracy of tare measurement directly affects downstream calculations and safety margins.

What Load Capacity Encompasses

Load capacity represents the portion of the GVWR available for payload. It accounts for distribution of weight across axles, tires, and frames to avoid overloading any single component. Properly interpreting load capacity requires understanding both the GVWR and the axle weight ratings, as overloading can cause tire blowouts, brake fade, or suspension damage. For modular equipment, the load capacity may vary with configuration, requiring explicit documentation for each setup to keep operations within safe limits.

Interpreting the Relationship: Tare Weight vs Load Capacity

Tare weight and load capacity are not opposites; they are complementary. The familiar relationship is: payload = GVWR − tare weight (and similarly for GCWR in combinations). A heavier tare reduces potential payload, even if gross limits are unchanged. Conversely, reducing tare through design improvements or lighter materials can expand usable payload without increasing total weight. This balance influences design choices, fuel economy, and maintenance planning, especially in fleets operating across diverse routes and regulations.

Calculations: Quick Formulas You Can Use

Key formulas help translate theory into practice. A common approach is: payload capacity = GVWR − tare weight. If you anticipate a multi-axle configuration or combination trailer, use GCWR for the overall upper bound and ensure each axle rating is respected. When planning specific loads, verify that the sum of axle loads does not exceed per-axle limits. Always document the assumptions behind these calculations, including fuel state, crew weight, and equipment attachments, as they affect the resulting payload estimates.

Practical Implications for Vehicles, Trailers, and Equipment

In vehicles and trailers, accurate tare weight and load capacity determine how much you can carry safely and legally. For example, a design with high tare weight reduces payload, potentially impacting revenue or mission feasibility. In equipment such as cranes, lift bodies, or service vehicles, misjudging load capacity can lead to unexpected weight distribution, steering or braking challenges, and maintenance costs. Across industries, standardized labeling and consistent measurement practices help maintain cross-vehicle compatibility and safer operations.

Common Pitfalls and Misconceptions

Common mistakes include assuming tare weight is static, neglecting fuel variance, or ignoring partial loads that shift weight distribution. Another pitfall is treating load capacity as identical to the actual safe payload; in reality, dynamic factors like road grade, braking requirements, and weather can change safe limits. Finally, misinterpreting GVWR or GCWR as a license to overload ignores critical safety margins and legal constraints.

Real-World Scenarios and Decision Tips

In practice, engineers and fleet managers benefit from documenting tare weight for each vehicle variant, establishing standard payload planning procedures, and using digital tools to simulate loads across routes. Decisions should weigh the total weight picture, including fuel, passengers, cargo, and attachments. For DIY projects, always verify that any added equipment’s weight does not push you past the vehicle’s rating, and consult manufacturer data when in doubt.

Comparison

| Feature | tare weight | load capacity |

|---|---|---|

| Definition | Weight of the empty vehicle/container (no payload or occupants) | Maximum payload the vehicle can safely carry within ratings |

| Units | kilograms or pounds | kilograms or pounds |

| Measurement Basis | Measured with no payload; may include standard fluids | Calculated from rating minus tare weight or specified by spec sheet |

| Impact on Payload | Higher tare reduces available payload at fixed GVWR | Larger load capacity increases usable payload under the same GVWR |

| Safety & Compliance | Directly affects GVWR/GCWR compliance and axle limits | Ensures loads stay within safe braking, handling, and legal limits |

| Variability | Tare can vary with fuel, fluids, equipment changes | Load capacity varies with vehicle configuration and rating updates |

| Practical Use Case | Payload planning for a given trip or mission | Engineering design and packing optimization for safe transport |

Positives

- Clarifies how much payload you can safely carry

- Improves safety and regulatory compliance

- Aids in route planning and logistics

- Helps optimize fuel efficiency by avoiding overloading

- Supports maintenance planning by tracking weight changes

Cons

- Requires accurate, up-to-date measurements

- Can be confusing for multi-axle configurations

- Not a substitute for checking gross vehicle weight in practice

Tare weight and load capacity are complementary concepts; managing both is essential for safe, compliant, and efficient transport.

Understanding both values helps prevent overloading, optimizes payload, and supports regulatory compliance. Use tare weight to determine available payload, and monitor load capacity to ensure every load remains within safe limits.

Quick Answers

What is tare weight, and why does it matter?

Tare weight is the weight of an empty vehicle or container, including standard equipment but excluding payload. It matters because it sets the baseline from which payload capacity is calculated, influencing safety, fuel efficiency, and regulatory compliance.

Tare weight is the empty weight. It matters because it defines how much cargo you can add without exceeding weight limits.

How is load capacity calculated for a vehicle?

Load capacity is typically calculated as the gross vehicle weight rating minus the tare weight. For trailers or complex configurations, GCWR minus tare weight or a per-axle rating may apply. Always verify against manufacturer data and local regulations.

Load capacity is GVWR minus tare weight. Check the exact specs for your setup.

Can tare weight change over time?

Yes. Changes in fuel, fluids, ballast, or added equipment can alter tare weight, which in turn changes payload capacity. Regular re-measurement helps maintain accurate planning.

Tare weight can change with fuel, fluids, or added equipment.

Why is load capacity important for safety?

Load capacity directly informs braking, handling, and structural integrity. Overloading can cause tire failure, brake fade, or frame damage, increasing accident risk and reducing lifespan.

Overloading risks tire failure and unsafe handling.

What should I do when planning mixed loads?

Document tare weight for each configuration, then verify that expected payload plus fuel and occupants stay within GVWR/GCWR and per-axle limits. Use simulation tools when available.

Document each setup and check limits before loading.

Top Takeaways

- Define tare weight and load capacity clearly for every vehicle

- Use payload = GVWR − tare weight to plan loads

- Regularly verify measurements to maintain safety margins

- Consider dynamic factors (fuel, passengers, attachments) when planning

- Document calculations for compliance and audits