Load Capacity vs Gross Vehicle Weight: A Practical Guide

Explore the differences between load capacity and gross vehicle weight, how to calculate each, and why understanding both matters for safety, planning, and regulatory compliance in engineering, fleet management, and DIY projects.

According to Load Capacity, the practical takeaway is to compare the current load against the published load-capacity limit rather than rely on approximate weights. In short, load capacity vs gross vehicle weight distinguishes safe payload from weight limits, guiding planning, safety, and regulatory compliance. Load Capacity recommends documenting both figures in maintenance logs and asset-management systems.

What the terms mean for engineers and technicians

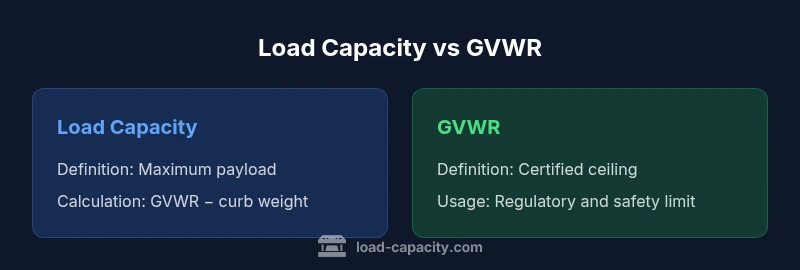

In engineering contexts, several terms describe similar ideas but with different meanings. The core concepts are load capacity (often called payload capacity), gross vehicle weight (GVW), and the regulatory ceiling GVWR (gross vehicle weight rating). Load capacity typically refers to the maximum payload a vehicle or structure can safely carry without compromising performance, handling, or structural integrity. GVW is the actual weight of the vehicle at a given moment, including the chassis, fluids, cargo, passengers, and any additional equipment. GVWR, by contrast, is the manufacturer-stated limit that should not be exceeded in normal operation. For practitioners, distinguishing load capacity from GVWR is essential when planning loads, distributing weight, and communicating with operators. As a guiding principle, the Load Capacity team emphasizes that operational decisions should hinge on payload limits while respecting the GVWR ceiling.

How regulators and standards interpret these terms

Regulatory frameworks distinguish between allowable vehicle weight and actual loaded weight. GVWR serves as a certification limit used by authorities to determine licensing, safety inspections, and road-usage rules. Exceeding GVWR can have legal consequences, affect warranties, and shift liability in the event of an incident. In practice, engineers and fleet managers reference placards on the vehicle (often near the door pillar) and the manufacturer’s documentation to verify GVWR. Load capacity remains a planning metric used for daily operations, ensuring that payload does not push the vehicle toward or beyond its certified limits. The key takeaway is that safety and compliance require both: a plan that respects payload capabilities and a check against GVWR before any operation falls under legal or insurance scrutiny.

Calculation methods and common confusion

A fundamental relationship ties these concepts together: Payload = GVWR − curb weight. GVW, the actual loaded weight, equals curb weight plus the payload currently on board. In everyday use, technicians should verify that the GVW remains at or below GVWR. When planning logistics, it helps to model loads in terms of payload capacity first, then validate feasibility with the GVWR ceiling. Be mindful that fuel, passengers, and optional equipment all contribute to GVW and can shift the effective payload quickly. Clarity comes from using standard weight-tracking practices and consistent load-distribution rules, avoiding ad hoc estimates that could lead to unsafe conditions.

Real-world examples across vehicle classes

Consider a compact passenger car, a light-duty pickup, and a full-size commercial truck. The car’s load capacity generally limits passengers and small cargo, while a pickup may offer a higher payload but still must respect GVWR when fully loaded with gear and equipment. A commercial truck often has a high GVWR but, because of design and axle configurations, distributes weight differently; payload must be planned with attention to axle load limits and center of gravity. In each case, the practical decision point is whether the intended load fits within the payload capacity while keeping the GVW under the GVWR. This approach reduces the risk of overloading and improves handling and braking performance.

Reading placards, labels, and technical sheets

Placards on doors and the owner’s manual provide the official GVWR and sometimes the curb weight. Technical sheets, dealer data, and OEM catalogs contain payload capacity figures and sometimes recommended load distributions. When uncertainty arises, cross-check the GVWR with the declared payload capacity and verify the current weight with a scale or calibrated method. Consistent documentation helps fleets maintain compliance and supports data-driven maintenance planning.

Implications for fleet planning and maintenance

Operational planning should integrate load-capacity targets into routing, scheduling, and maintenance. Recording payload usage, regularly reviewing load distributions, and coordinating with maintenance teams on after-action checks are good practices. A well-structured weight-management program can improve fuel efficiency, stability, and tire wear while reducing the likelihood of axle or suspension damage. The broader takeaway is that load capacity should drive day-to-day decisions, with GVWR acting as the legal constraint. In long-running operations, dynamic weight management helps sustain performance across changing loads and routes.

How to compare options using a standard framework

A standard framework for comparing load-capacity approaches vs GVWR-based approaches includes: 1) Identify the published payload capacity and GVWR; 2) Estimate current GVW for typical loads; 3) Check if the planned load stays within payload limits; 4) Assess weight distribution and axle loading; 5) Validate against regulations and insurance requirements. This framework supports consistent decision-making and reduces ambiguity when equipment is repurposed or loads vary across operations.

Common pitfalls and misconceptions

- Confusing GVWR with actual weight at a given moment. - Assuming payload capacity remains constant regardless of fuel, passengers, or upgrades. - Relying solely on one metric without cross-checking the other. - Ignoring weight distribution and center of gravity effects when loading. - Viewing payload as “unused space” rather than a critical safety limit. A clear, dual-metric approach minimizes these risks.

Practical steps for engineers and technicians to implement

- Create a standard weight-tracking protocol across fleets. - Train operators to read placards and verify GVWR before loading. - Integrate payload calculations into maintenance and asset-management systems. - Use load-distribution charts for weight-bearing axles and tires. - Periodically audit loads versus payload capacity and GVWR to identify trends and take corrective actions.

Comparison

| Feature | load-capacity approach | gvwr-based approach |

|---|---|---|

| Definition | Payload-centric planning: limits determined by payload capability (load capacity) | Compliance-centric planning: limits determined by GVWR (regulatory ceiling) |

| Calculation method | Payload = GVWR − curb weight; consider actual loading | GVW = curb weight + payload; ensure GVW ≤ GVWR |

| Data sources | Vehicle spec sheets, OEM payload figures, and weight-management systems | Placards, owner's manual, and manufacturer GVWR documentation |

| Best for | Daily planning, weight distribution, and performance optimization | Regulatory compliance, licensing, and safety-critical operations |

| Typical risk | Underutilizing capacity if misinterpreted; better control of handling and stability | Overload and legal liability if GVWR is exceeded; potential fines and warranty issues |

Positives

- Clarifies safety margins for payload planning

- Improves load distribution and vehicle stability

- Supports fleet-wide weight-management and maintenance planning

- Aligns operational choices with engineering and safety objectives

Cons

- Requires consistent data collection of curb weight and actual load

- Can be confusing if teams focus on one metric without cross-checking the other

- May seem to underutilize capacity if not integrated into planning systems

Use a dual-criteria approach: prioritize payload capacity for planning while always validating against GVWR checks.

Operational decisions should hinge on payload limits to optimize performance and safety, with GVWR serving as the legal ceiling. The Load Capacity team recommends training teams to read placards, document both metrics, and use them in maintenance logs to ensure consistency across operations.

Quick Answers

What is the difference between load capacity and payload capacity?

Load capacity typically refers to the maximum payload a system can safely carry, while payload capacity is the amount of payload the system can actually hold under operating conditions. In practice, payload capacity is used for planning, whereas load capacity is the theoretical limit.

Load capacity is the maximum safe payload. Payload is what you actually put on the vehicle; always compare the real payload to the limit.

How do you calculate payload capacity on a vehicle?

Payload capacity is calculated as GVWR minus curb weight. This yields the maximum payload the vehicle can carry safely under standard conditions. Always verify the curb weight from official specs and use a scale or accepted weighing method for accuracy.

Payload equals GVWR minus curb weight; check official specs and weigh the vehicle to confirm.

Is GVWR the same as gross vehicle weight rating?

GVWR stands for gross vehicle weight rating and represents the maximum allowed weight of the vehicle when fully loaded. Gross vehicle weight (GVW) is the actual weight at a given moment, including cargo, passengers, and fluids. They relate but are not the same thing.

GVWR is the limit; GVW is the actual weight at a moment.

Why does payload capacity matter for axle load and stability?

Payload affects how weight is distributed across axles and tires. Exceeding payload limits can increase axle loads beyond design, reducing stability, braking performance, and tire life. Proper payload planning helps maintain balance and control.

Payload affects axle loads and stability; stay under limits to keep control and tire life.

Can load capacity ever exceed GVWR in practice?

In practice, load capacity is defined to stay within the GVWR. If the payload is high but the GVWR is low, the vehicle cannot legally or safely carry that load. Always plan with payload and verify GVWR as the ultimate constraint.

Payload should never exceed GVWR; GVWR is the ceiling you must observe.

Top Takeaways

- Identify GVWR and curb weight before loading.

- Calculate payload as GVWR minus curb weight.

- Always verify actual weight (GVW) stays below GVWR.

- Distribute weight to avoid axle overload.

- Document both metrics in fleet records.