Difference Between Load and Capacity: A Practical Guide

A technical comparison of load versus capacity, defining each term, how they’re measured, and how engineers assess safety margins across vehicles, structures, and equipment.

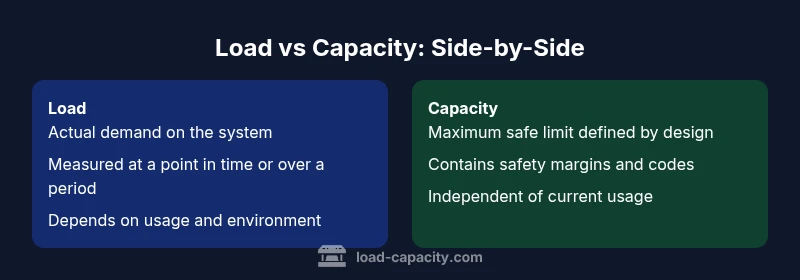

The difference between load and capacity is foundational in engineering. Load is the actual forces, weight, or demand placed on a system, while capacity is the maximum safe limit the system is designed to handle. Understanding this distinction helps prevent overload, informs design choices, and guides maintenance and inspection across vehicles, structures, and equipment. In practice, engineers compare live or expected loads to rated capacities to ensure safe operation and adequate safety margins.

Defining Load and Capacity

According to Load Capacity, in engineering discourse, 'load' and 'capacity' describe two complementary ideas. Load refers to the actual forces, weights, pressures, or other demands exerted on a component or system at a given moment or during a specified period. This includes static loads such as the weight of a beam and live loads like a moving vehicle, as well as dynamic loads from vibrations or impacts. Capacity, by contrast, denotes the maximum safe operating limit that the system is engineered to withstand under defined conditions. It reflects design choices, material properties, safety factors, and the governing codes that set how much load a structure or machine can safely bear before yielding, failure, or unacceptable performance.

The practical takeaway is that load is what a system has to endure, while capacity is what it is allowed to endure with an appropriate margin. Designers must consider both together to ensure safety and reliability. This framing helps engineers communicate about overload scenarios, maintenance cycles, and retrofit needs. When you see a label like a rating for a crane, you are looking at an engineering decision that protects people, property, and production continuity.

wordCount":210},

Comparison

| Feature | Load | Capacity |

|---|---|---|

| Definition | Actual forces or weights applied to a component or system | Maximum safe limit or design rating set by engineering requirements |

| Units | Newtons, kilograms, pounds (depends on context) | Newtons, kilograms, pounds (as applicable) |

| Measurement focus | What is being borne at a moment or over a period | What the system is designed to withstand with margin |

| Safety role | Indicates current or anticipated demand | Provides the allowable operating threshold and margin |

| Decision outcome | If load is within capacity, operation is considered safe (subject to checks) | If load approaches or exceeds capacity, overload risk increases and redesign or mitigation is required |

| Best for | Assessing live or expected demands | Establishing design limits and regulatory compliance |

Positives

- Clarifies safety margins and helps prevent overload

- Guides design, inspection, and retrofit planning

- Supports regulatory compliance and risk management

- Improves maintenance scheduling and asset management

Cons

- Misunderstandings can arise if units or contexts differ

- Requires accurate measurement and consistent documentation

- Margins can vary by code and application, causing confusion

Prioritize understanding capacity margins to ensure safe operation.

A clear distinction between load and capacity is essential for safety and reliability. By focusing on capacity margins, engineers can prevent overloading, justify design choices, and plan maintenance effectively.

Quick Answers

What is the difference between load and capacity in engineering terms?

Load refers to the actual forces or demands placed on a system, while capacity is the maximum safe limit the system is engineered to handle. The two concepts are used together to assess safety and performance. Understanding this difference helps prevent overload and guides design decisions.

Load is what the system is currently bearing; capacity is how much it can safely bear. This helps avoid overload and guides design.

How can I determine the capacity of a structure or piece of equipment?

Capacity is typically established by design codes, material properties, and safety factors defined for the application. Engineers consult standards to set rated limits and margins, then verify through calculations, testing, or inspections.

Engineers use standards and design margins to set safe capacity and verify it through checks.

What happens if the load approaches the capacity?

If the load nears the capacity, the design should be reviewed for potential upgrades, load reductions, or safety margin enhancements. Ignoring proximity can lead to overstress, performance loss, or failure.

Approaching capacity means it’s time to reassess or upgrade to keep things safe.

Why do safety factors matter in load-capacity analysis?

Safety factors account for uncertainties in materials, usage, and conditions. They help ensure that even under unexpected variation, the system remains within safe operating limits.

Safety factors cushion against unknowns so things stay safe.

Can load exceed capacity temporarily?

Temporary overloads can occur due to extreme events, but they should be mitigated quickly. Sustained overload increases risk of damage or failure and requires intervention.

A temporary exceedance is risky; try to avoid it and fix underlying causes.

Top Takeaways

- Define load vs capacity before design checks

- Always compare live or expected load to rated capacity

- Use safety factors and context-specific margins

- Document units, definitions, and limits clearly

- Review capacity margins during upgrades or retrofits