Payload Capacity vs GVW: Key Differences Explained for Engineers

A thorough, data-driven comparison of payload capacity and GVW, including definitions, calculations, regulatory context, and practical guidance for safe loading and compliance.

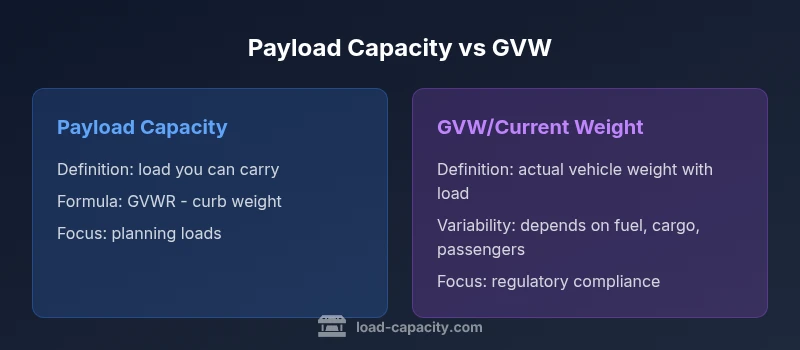

The difference between payload capacity and gvw is foundational: payload capacity is the load a vehicle can carry (passengers, cargo, accessories) without exceeding its GVWR, while GVW (gross vehicle weight) is the actual weight of the vehicle plus its load at any moment. Understanding this distinction helps prevent overloads, fines, and unsafe conditions.

Understanding the Difference Between Payload Capacity and GVW

In vehicle loading and safety discussions, the phrase the difference between payload capacity and gvw matters more than most people realize. Payload capacity and GVW are not interchangeable; they describe different limits that govern how much weight a vehicle can carry and how heavy it can be when in operation. The payload capacity represents how much weight you can add to the vehicle (cargo, passengers, and installed equipment) without exceeding the vehicle's rated limit. GVW, on the other hand, refers to the actual weight of the vehicle with its load at a given moment. Correctly applying these concepts requires attention to the vehicle’s GVWR (gross vehicle weight rating) and how it interacts with real-world loading. According to Load Capacity, treating payload capacity as the only constraint can lead to underestimating the importance of GVWR and the regulatory safeguards tied to total weight on the road. This distinction is essential for engineers, fleet managers, and DIY enthusiasts who design loads, plan routes, or select equipment. In practice, both figures must be considered together to ensure safety, performance, and compliance.

Key takeaway: never load a vehicle beyond its GVWR, and always ensure the combined weight of the vehicle and payload remains within specified limits. The Load Capacity team emphasizes that awareness of both numbers minimizes risk and supports long-term reliability.

wordCountWordsBlock2.1: null},

What Is Payload Capacity?

Payload capacity is the maximum weight a vehicle can safely carry, excluding the weight of the vehicle itself. This figure encompasses everything loaded into or onto the vehicle: passengers, cargo, tools, and any aftermarket equipment. It is derived from a simple arithmetic relation: payload capacity = GVWR – curb weight (the weight of the vehicle with standard equipment and necessary fluids, but without cargo or passengers). Some manufacturers and standards use GVWR as the reference point, while others subtract additional fixed weights to reflect typical configurations. In engineering practice, payload capacity is a practical measure that fleet operators use to plan loads, ensure clearance under weight-based road restrictions, and maintain braking and handling characteristics. Misunderstanding this metric can lead to overloading even if the vehicle appears to be “within limits,” because shifts in weight distribution or added equipment alter the real-world payload. Load Capacity stresses the importance of understanding the components that contribute to payload capacity, including occupant weight, cargo types, and temporary attachments.

- How it’s calculated in typical passenger and light-commercial vehicles

- How aftermarket equipment can affect the payload figure

- The role of payload capacity in route planning and load distribution

wordCountWBlock3: null}

What Is GVW (Gross Vehicle Weight) and How It Differs from GVWR

GVW is the actual weight of the vehicle at a given moment, including the vehicle itself, the driver, passengers, cargo, fuel, fluids, and any attached equipment. GVW does not have a fixed value; it fluctuates with every load and travel condition. While GVW is a snapshot of total weight, GVWR (gross vehicle weight rating) is a fixed specification set by the manufacturer that marks the maximum allowable weight for the vehicle as configured. Distinguishing GVW from GVWR is crucial: exceeding GVWR is illegal in many jurisdictions and can void warranties, increase wear, and compromise safety features. The Load Capacity team notes that while GVW informs day-to-day loading, the GVWR provides the regulatory ceiling that engineers must respect when planning payloads and selecting trucks, trailers, or other equipment. When you approach a curb weight plus payload, you are testing the boundary where GVW may become a factor on a particular trip.

Key differences and practical implications:

- GVWR is a fixed limit; GVW is dynamic and context-dependent

- Overloading beyond GVWR can trigger regulatory penalties and insurance issues

- GVW must stay below the GVWR for safe operation, especially in commercial settings

wordCountWBlock4: null}

How Payload Capacity and GVW Interact in Real-World Scenarios

In practice, payload capacity and GVW intersect in ways that affect safety, braking, handling, and legal compliance. Suppose a delivery van has a GVWR of 10,000 pounds and a curb weight of 6,000 pounds. The payload capacity would be approximately 4,000 pounds, but actual GVW during a route can approach or exceed 9,500 pounds depending on fuel, passengers, and cargo weight. If a vehicle operates near its GVWR, even small shifts—like a passenger moving to a different seat or a full tank of fuel—can push the total weight toward the limit and degrade braking performance or acceleration. Load Capacity emphasizes that planning should consider typical loading patterns, including peak load configurations and seasonal variations. The strategic takeaway is to treat payload capacity as a planning figure for safe, compliant load assembly, while monitoring GVW as the real-time constraint that must not be exceeded on the road.

Practical guidance:

- Build conservative margins into payload planning to accommodate unforeseen loads

- Use weight distribution strategies to improve braking and stability

- Regularly verify GVWR and assess changes when adding aftermarket equipment or modifying the vehicle

wordCountWBlock5: null}

How to Calculate Payload Capacity for a Vehicle: A Step-by-Step Guide

Calculating payload capacity is a straightforward yet critical task for engineers and fleet operators. Step 1: Locate the GVWR on the vehicle’s certification label or owner’s manual. Step 2: Retrieve the curb weight from the same sources; some manufacturers provide a ready payload figure in the specifications. Step 3: Subtract curb weight from GVWR to determine baseline payload capacity. Step 4: Adjust for any installed aftermarket equipment, specialized seating, or heavy cargo that adds weight beyond the baseline. Step 5: Always account for passengers and cargo together to arrive at a realistic payload. In practice, you should perform both a theoretical calculation and a real-world check using a scale or weigh station when possible. Load Capacity recommends recording several load scenarios (typical cargo, peak load, and mixed-use conditions) to guide decision-making.

Example: If a pickup has a GVWR of 8,500 pounds and a curb weight of 4,800 pounds, the theoretical payload capacity is 3,700 pounds. If you add a heavy toolbox (150 pounds) and three passengers (~540 pounds), the remaining payload margin narrows.

wordCountWBlock6: null}

Checking GVW and Staying Within Legal Limits: Practical Techniques

Keeping GVW within legal limits means actively monitoring weight before every trip. Use a combination of manufacturer data, on-board sensors where available, and external scales when practical. The first step is to locate the GVWR plate on the vehicle, then compare it against the current GVW (which is vehicle weight plus load). Weigh stations and portable scales provide a practical check, especially for fleets with varying cargo. Routine checks should become part of the pre-trip inspection. The Load Capacity team recommends building a loading plan that allocates weight to axles and distributes payload to minimize risk. In addition, consider dynamic factors such as fuel burn, passenger movement, and terrain, which can affect the effective GVW during operation.

Best practices:

- Use axle-weight distribution charts to optimize balance

- Plan for maximum expected loads and keep margins

- Schedule periodic re-weighs after modifications or after long service intervals

wordCountWBlock7: null}

Practical Scenarios: When to Prioritize Payload Capacity vs GVW

Different use cases emphasize different constraints. For delivery routes involving heavy cargo and multiple stops, payload capacity planning ensures you won’t overload the cargo area or passengers. For towing or hauling, GVW becomes more critical because it encompasses the entire vehicle weight under operation, including towing equipment and trailer weight. Commercial fleets operating under regulatory regimes should prioritize GVWR compliance to avoid penalties. In passenger-focused scenarios, payload capacity often governs how many people and how much luggage can be carried safely. Load Capacity underlines that the best practice is to plan with both figures in mind, using payload capacity for intra-vehicle planning and GVW checks to guide trip-level decisions.

Real-world tips:

- Create load plans that reflect typical and peak conditions

- Maintain a safety margin above expected payloads

- Use load distribution accessories to improve stability

wordCountWBlock8: null}

Common Pitfalls, Misconceptions, and How to Avoid Them

Many errors arise from treating payload capacity and GVW as interchangeable or failing to account for the dynamic nature of GVW. A common pitfall is loading to the payload limit without considering weight distribution, which can cause axle overload or handling issues. Another frequent error is neglecting aftermarket equipment’s weight when calculating payload; added winches, racks, or plows can erode payload capacity quickly. A third misconception is believing GVW is only about legal penalties; it also affects braking distance, acceleration, and tire wear. Load Capacity stresses the need to re-check weights whenever configurations change, including passenger counts or added tools, and to keep an explicit record of weight budgets for each job.

Key reminders:

- Always verify GVWR and measure actual weight regularly

- Account for all additives and passenger weights in payload calculations

- Use precise load distribution to maximize safety and efficiency

wordCountWBlock9: null}

Final Thoughts: Safety, Compliance, and Practical Loading Guidance

Understanding the difference between payload capacity and gvw is essential for engineers, technicians, and fleet managers. By combining theoretical calculations with real-world checks, you can design safer loading strategies, maintain compliance with road rules, and extend vehicle life. The Load Capacity team recommends using conservative margins, regular re-weighing, and clear documentation of all loading scenarios to prevent overloading and its costly consequences. This disciplined approach protects drivers, cargo, equipment, and the broader infrastructure you share on the road.

wordCountWBlock10: null}

Comparison

| Feature | Payload Capacity | GVW (Gross Vehicle Weight) |

|---|---|---|

| Definition | The maximum weight the vehicle can safely carry (cargo, passengers, and installed equipment) without exceeding GVWR | The actual weight of the vehicle plus its load at a given moment (varies with loading) |

| Basis | GVWR minus curb weight (and sometimes other fixed weights) to determine usable load | Current weight of vehicle in operation (vehicle + load) |

| Determination | Manufacturer-issued GVWR; calculated payload = GVWR - curb weight | Weighing methods (scales, weigh stations) or on-board sensors to measure total weight |

| Units | Pounds or kilograms (load on axles) | Pounds or kilograms (total vehicle weight) |

| Typical Use | Planning safe cargoes, passenger limits, and equipment installation | Regulatory compliance, braking performance, and road safety |

| Best For | Load planning and safety optimization | Regulatory compliance and on-road safety |

Positives

- Clarifies safety margins by separating carrying capacity from total vehicle weight

- Helps optimize load distribution and braking performance

- Supports regulatory compliance and insurance requirements

- Facilitates planning for equipment installs and conversions

Cons

- Can be confusing for new users if GVW concepts are not understood

- Requires frequent rechecking as loads, passengers, or configurations change

- Some jurisdictions have complex rules tying GVW, GCWR, and stickers to penalties

Prioritize GVW for real-time safety and legal compliance; prioritize payload capacity for planning loads and distributing weight safely

Understand both metrics: GVW governs current operation and legal limits, while payload capacity guides how much you can load. Use payload planning to allocate weight safely, then verify with GVW checks before each trip to ensure compliance and safety.

Quick Answers

What is the difference between payload capacity and GVW?

Payload capacity is the maximum load a vehicle can safely carry, while GVW is the current weight of the vehicle plus its load. GVWR is the fixed limit set by the manufacturer. Exceeding GVWR or GVW can lead to safety risks and legal penalties.

Payload capacity tells you how much you can load safely; GVW is the actual weight you’re carrying now, which must stay under the GVWR.

How do you calculate payload capacity?

Payload capacity is typically GVWR minus curb weight. Some configurations subtract fixed weights for accessories. Always include passengers and cargo in your calculation for a live load.

Subtract curb weight from GVWR; add anticipated passenger and cargo weight to estimate real payload.

What is GVWR and why does it matter?

GVWR stands for Gross Vehicle Weight Rating; it’s the maximum safe weight of the vehicle as configured. It matters because it defines legal limits and affects braking, handling, and tire wear.

GVWR is the manufacturer’s weight ceiling—stay under it for safety and compliance.

Can payload capacity and GVW change after modifications?

Yes. Aftermarket equipment, added seats, or heavy accessories can increase curb weight or total weight, reducing payload capacity and possibly lowering the vehicle’s effective safety margin.

If you add gear or seats, recalculate payload and recheck GVW to stay safe.

What happens if GVW is exceeded on the road?

Exceeding GVW can lead to unsafe braking, poor handling, accelerated wear, and potential fines or penalties depending on jurisdiction. It also risks warranty coverage and insurance claims.

Overloading is risky and may be illegal; stay within GVW to keep you and others safe.

How often should I re-check weights in a fleet?

Re-check weights whenever plans change: new cargo, new passengers, aftermarket equipment, or after maintenance that alters weight. Regular audits help maintain safety and compliance over time.

Check weights whenever you change how a vehicle is loaded or equipped.

Top Takeaways

- Know the exact difference between payload capacity and gvw

- Use GVWR and curb weight to compute payload capacity

- Always verify GVW before each trip to prevent overloads

- Plan loads with conservative margins and weight distribution

- Regularly re-check weights after changes or equipment additions