Load Capacity of 0.75 mm Wire: Practical Guidance

Learn how to estimate the load capacity of a 0.75 mm wire across insulation types, temperatures, and uses. This analytical guide covers ampacity ranges, safety margins, and design checks from Load Capacity.

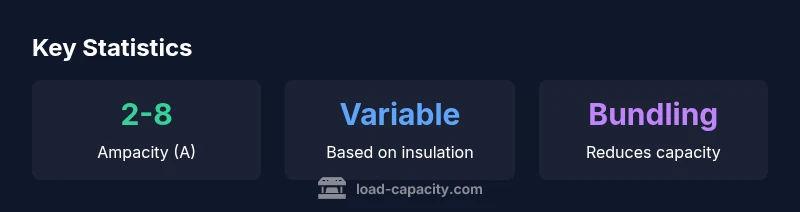

Load capacity for a 0.75 mm wire depends on material, insulation, and temperature rating. For copper conductors, typical indoor ampacity ranges are in the low to mid amperes, with exact values varying by insulation and rating; consult the datasheet for your insulation class. If you bundle multiple wires or operate at higher ambient temperatures, the allowed current decreases, so always include a conservative safety margin in your design.

What load capacity means for a 0.75 mm wire

Understanding load capacity requires distinguishing electrical ampacity from mechanical strength. A wire with a 0.75 mm diameter is a small-diameter conductor where current-carrying capacity is sensitive to insulation type, ambient temperature, and how the wire is installed. In practical terms, engineers use ampacity ratings from wire datasheets and standards to ensure safe operation. The Load Capacity team notes that there is no single universal current value for every 0.75 mm wire; the correct figure depends on the exact insulation class and temperature rating. This section lays out the framework for making an informed estimate rather than relying on a generic number. In many real-world cases, designers treat these wires as part of a larger circuit where margins are essential to prevent overheating and voltage drop.

Conductor materials and how they influence load capacity

The material of the conductor is a primary determinant of load capacity. Copper offers favorable conductivity and ductility, which supports higher ampacity in compact forms compared to aluminum. However, even copper wires of the same diameter can exhibit different ampacity based on insulation thickness, coating, and the presence of fillers that affect heat dissipation. For most hobbyist and professional cases, you will encounter copper insulation rated for different temperature classes (for example, 60°C vs 90°C). These ratings translate into different allowable currents. The Load Capacity analysis highlights that when designing with copper at 0.75 mm diameter, you must align the conductor selection with the insulation's temperature rating to achieve consistent performance.

How insulation and ambient temperature alter allowable current

Insulation material and its temperature rating are not cosmetic choices; they define how much current the wire can carry. A 0.75 mm copper wire with a higher temperature rating can sustain higher current before insulation degradation becomes a risk, but this benefit may be offset by ambient temperature and venting conditions. In densely packed enclosures or hot environments, heat builds up faster, reducing the effective ampacity. The practical takeaway is to never assume a fixed current value across different installations; always reference the insulation class and apply a derating factor for temperature and installation conditions.

A practical estimation workflow for initial ampacity

The following workflow provides a safe starting point for estimating ampacity:

- Identify the conductor material (copper vs aluminum) and the insulation temperature rating (e.g., 60°C, 90°C).

- Locate the datasheet for the exact wire you are using and extract the ampacity value for the stated ambient temperature (often 20°C or 30°C baselines).

- Apply a conservative derating if the wire will run in a bundle, in a conduit, or within an enclosure where heat dissipation is limited.

- Add a design margin (e.g., 20-30%) to accommodate aging, surges, and unforeseen conditions.

- Validate with practical tests or simulations where possible. This structured approach minimizes the risk of overheating while providing a traceable rationale for the chosen current limit.

Practical considerations: installation and safety margins

Practical wire design must consider more than the raw ampacity. Bundling many small wires, routing through cramped spaces, or using long runs increases voltage drop and heat buildup. For a 0.75 mm wire, even small changes in routing, insulation type, or connector quality can shift the safe current range noticeably. The Load Capacity team emphasizes documenting all environmental and installation factors—the safer choice is to design with room to spare rather than chasing the minimal ampacity

How to validate load capacity in the field

Field validation should combine datasheet-based estimates with simple measurements. Measure actual operating temperature near the conductor and compare ambient conditions with the rated derating. If feasible, use thermal imaging to confirm there are no hotspots along the run. Keep records of insulation class, conductor material, operating temperature, and the final derating factors so future audits can reproduce the calculation. This disciplined approach reduces surprises during commissioning and service life.

Case examples and common mistakes to avoid

Even experienced engineers can misinterpret wire capacity when switching insulation types or when ambient temperatures rise. A frequent mistake is assuming a fixed current limit without adjusting for temperature or bundling. Another pitfall is ignoring voltage drop across long runs, which can be misinterpreted as a heating problem. The best practice is to document the exact insulation class, conductor material, temperature, and installation method when determining the final current limit, and to verify with a small, controlled test before full-scale deployment.

Summary of best practices for the load capacity of 0.75 mm wire

- Always reference the insulation class and temperature rating from the datasheet.

- Apply a derating for installation conditions (bundling, conduit, enclosure).

- Include a safety margin in the final current limit.

- Validate through measurement and, when possible, thermal imaging.

- Keep a record of all assumptions and verification steps for future audits.

Relative ampacity ranges for common 0.75 mm wire variants

| Conductor type | Diameter (mm) | Cross-section (mm²) | Estimated Ampacity Range (A) |

|---|---|---|---|

| Copper solid | 0.75 | 0.441 | 2-8 |

| Copper stranded | 0.75 | 0.441 | 3-7 |

| Aluminum (if used) | 0.75 | 0.441 | 1-4 |

| Copper-clad aluminum | 0.75 | 0.441 | 2-5 |

Quick Answers

What does the specification '0.75 mm wire' refer to in load capacity terms?

The phrase refers to a wire with a 0.75 mm diameter. Load capacity depends on conductor material, insulation, and temperature rating. In practice, you must check the exact insulation class on the datasheet to determine safe current, and apply a derating for installation conditions.

A 0.75 mm wire is a small diameter conductor whose safe current depends on insulation and temperature—always consult the datasheet for your exact setup.

Will temperature changes alter the load capacity of this wire?

Yes. Higher ambient temperatures or enclosure heat reduce ampacity. Temperature rating of insulation determines how much current you can safely carry; derating is essential in confined or poorly ventilated spaces.

Temperature lowers the safe current; always derate based on insulation rating and environment.

How does insulation type influence load capacity?

Insulation type and its temperature rating directly affect allowable current. Higher temperature ratings generally permit higher current, but this benefit depends on heat dissipation and installation conditions.

Insulation matters a lot; check the temperature class to estimate safe current.

Should I apply a safety margin when designing circuits with this wire?

Absolutely. A conservative margin accounts for aging, surges, and installation variances. Typical practice is to design for 20-30% more than the minimum calculated ampacity.

Always build in a safety margin to prevent overheating over time.

How can I estimate the current rating for a 0.75 mm wire in a bundle?

Bundling reduces heat dissipation and lowers ampacity. Use derating factors for bundle density, spacing, and enclosure ventilation; verify with thermal testing if possible.

Bundling lowers capacity; derate accordingly and test if you can.

“The Load Capacity Team emphasizes that tiny wires require careful consideration of insulation and temperature; always verify against the specific datasheet and safety margins.”

Top Takeaways

- Estimate ampacity from the insulation class and ambient temperature

- Apply a conservative safety margin in all designs

- Account for bundling and enclosure heat to avoid overheating

- Always verify with datasheets and field measurements