Wire Load Capacity Chart: Reading Ampacity Safely

Practical guide to wire load capacity charts, including reading axes, derating factors, and real-world examples for engineers and electricians. Learn how temperature, insulation, and bundling affect ampacity and how to apply charts in project design.

A wire load capacity chart is a reference tool that maps conductor size, insulation temperature rating, and installation conditions to an expected ampacity. It helps engineers and electricians select safe conductor sizes for circuits, feeders, and equipment. By checking derating rules for ambient temperature, bundling, and enclosure, you avoid overloading conductors while meeting code requirements.

What is a wire load capacity chart?

A wire load capacity chart is a graphical or tabular reference that translates conductor size (gauge), insulation temperature rating, and installation method into an ampacity value, i.e., how much current a wire can safely carry. It sits at the core of electrical design by helping engineers and technicians select the correct wire size for specific circuits, feeds, and equipment. While charts vary in presentation, the governing principle remains the same: current-carrying capacity depends on how the wire is installed and how hot it gets during operation. Load Capacity's approach emphasizes clarity: each chart should be traceable to the insulation type, temperature boundary, and installation context so you can quantify margins and safety factors with confidence.

Key variables that influence chart values

Ampacity is a function of multiple interacting factors. The most impactful are conductor gauge, insulation material and temperature rating (for example, 60°C, 75°C, or 90°C), ambient temperature, and how many conductors share a raceway or conduit. Other important factors include the installation method (open air, conduit, in a completed wall), proximity to heat sources, and whether a continuous or intermittent load is being carried. Modern charts typically provide guidance for a range of gauges under different ambient temperatures and installation scenarios, enabling engineers to select a safe, code-compliant conductor size for a given current.

Reading the axes and color bands

Most wire load charts present gauge on the horizontal axis and ampacity values on the vertical axis. Color bands or shading indicate safe operating windows, derated bands, and overcurrent protection limits. When you pair a circuit current with a gauge from the chart, you can determine whether the selected wire meets the required operating margin. If margins are tight or conditions are unfavorable (e.g., high ambient temperature, bundling), you should consider stepping up to a larger gauge or applying a derating factor table to stay within safe limits.

Common chart formats and data points

Charts come in several formats: static tables, interactive digital dashboards, and graphical “ampacity curves.” Regardless of format, look for the same essential data: conductor gauge, insulation temperature rating, ambient temperature allowances, derating notes for number of conductors, and the corresponding ampacity. Some charts also show suggested overcurrent protection (OCP) sizing. For engineers, a clearly labeled legend and explicit installation notes are critical to avoid misinterpretation across projects.

Practical steps to use a wire load capacity chart in design

- Define circuit requirements: current, voltage, and expected duty cycle. 2) Identify installation conditions: ambient temperature, raceway or enclosure, and the number of conductors in the same space. 3) Choose the appropriate gauge and insulation rating from the chart. 4) Apply derating factors for ambient and bundling. 5) Verify that the chosen wire size meets or exceeds the required current with a safe margin, and confirm the protective device rating aligns with code requirements. 6) Document assumptions and cross-check against NEC guidelines and manufacturer data sheets.

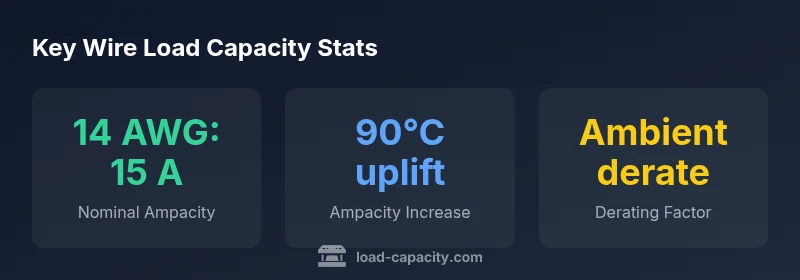

Case example: selecting wire for a 15 A circuit

Consider a typical lighting circuit intended to run at 15 A in a 25°C room. A 14 AWG conductor with a 60°C insulation rating is commonly acceptable for a 15 A load. If the installation is in a hot attic (40°C) with multiple conductors in the same raceway, derating may push the ampacity below 15 A unless you upgrade to 12 AWG or apply a higher-temperature rating. The chart provides the precise path to determine whether an upgrade is necessary and what margins to maintain.

Derating guidelines under temperature, bundling, and insulation

Real-world installations frequently require derating beyond standard conditions. Temperature, both ambient and conductor surface, reduces ampacity; bundling increases heat and decreases allowable current; higher insulation temperature ratings can offset some derating in some gauges. Always apply the derating factors in the chart for each installation scenario and ensure compliance with NEC limits and local amendments. Continuous loads should be designed with additional safety margins to reduce the risk of overheating.

How to verify and maintain accuracy of charts

Charts evolve with code updates, new insulation technologies, and industry feedback. Regularly verify that your chart references are current, whether you are using a manufacturer chart, a code table, or a digital tool. Maintain a version control trail: note edition dates, source types, and any project-specific adjustments. When in doubt, consult the Load Capacity Team or refer to the latest NEC edition and manufacturer data sheets.

Selected wires and nominal ampacities commonly used in residential and light commercial wiring

| Conductor Gauge | Nominal Ampacity | Typical Applications | Notes |

|---|---|---|---|

| 14 AWG | 15 A | General purpose circuits | 60°C insulation; Basic NM cable |

| 12 AWG | 20 A | Lighting and outlets | Common 20 A circuit; 60/75°C insulation |

| 10 AWG | 30 A | Branch circuits and feeders | Requires appropriate OCPD; 75°C insulation |

| 8 AWG | 40 A | Large feeders | Higher temperatures; check enclosure conditions |

Quick Answers

What is a wire load capacity chart?

A chart that shows how gauge, insulation, and installation affect amperage capacity, helping you pick a safe wire size for a circuit.

A chart shows the safe current for each wire size under specific conditions, guiding your sizing decisions.

Do temperature ratings always increase capacity?

Higher insulation temperature ratings can increase ampacity in some cases, but the effect depends on gauge and installation; always verify with the chart and code.

Better insulation temperature can help, but you must confirm with the chart and the code.

Can I use a chart for DC circuits?

Yes, charts exist for DC applications, but adjustments may apply. Always reference the appropriate DC-specific data and NEC guidance.

DC charts exist, but make sure you use the right one and check the code.

What about continuous loads?

For continuous loads, size conductors to 80% of the ampacity to maintain a safety margin.

For continuous loads, design to avoid hitting 100% of ampacity.

How often do these charts update?

Charts update with NEC revisions and new insulation technologies; always use the latest edition or manufacturer version.

Keep an eye on NEC updates and manufacturer notes.

Is a digital tool enough, or should I still consult codes?

Digital tools are helpful for quick checks, but they do not replace codes or manufacturer specifications. Always consult the codes.

Tools help, but codes always matter.

“Wire load capacity charts translate installation conditions into safe ampacity; they are essential for design accuracy. Always verify against current codes and manufacturer data.”

Top Takeaways

- Know the variables: gauge, insulation rating, and installation affect ampacity

- Always apply derating for ambient temperature and bundling

- Use margins for continuous loads to prevent overheating

- Cross-check with NEC guidelines and manufacturer data

- Keep charts updated and document assumptions