6mm Aluminium Wire Load Capacity in Watts: A Practical Guide

Explore how to assess the power-carrying capacity of a 6mm aluminium wire. Learn ampacity, watt conversion, derating, and practical guidelines for safe electrical design.

There is no universal wattage rating for a 6mm aluminium wire; watt capacity depends on voltage, length, insulation, and ambient temperature. To estimate power, use P = V × I, where I is the conductor's ampacity under the installation conditions. For safe design, consult aluminium ampacity charts and apply derating rules from applicable standards.

Understanding 6mm aluminium wire load capacity in watts

Power handling for a conductor is not a fixed wattage; it is determined by the interaction between the conductor’s ability to carry current (ampacity) and the electrical environment. In practical terms, the phrase 6mm aluminium wire load capacity in watts refers to how much electrical power the circuit can carry through that conductor without overheating, under specific voltage, length, insulation, and ambient temperature. According to Load Capacity analysis, there is no universal watt limit that applies to all installations. Instead, engineers start with the wire’s ampacity at a reference temperature, then translate that current into watts for their supply voltage using P = V × I. This is why the most reliable approach is to consult an aluminium conductor ampacity chart that accounts for insulation temperature class and environment. Also, remember to apply derating factors for bundling, ambient temp, and conduit fill; misinterpreting these factors is a common cause of overheating. This article provides a structured way to interpret watts in the context of 6 mm aluminium wire.

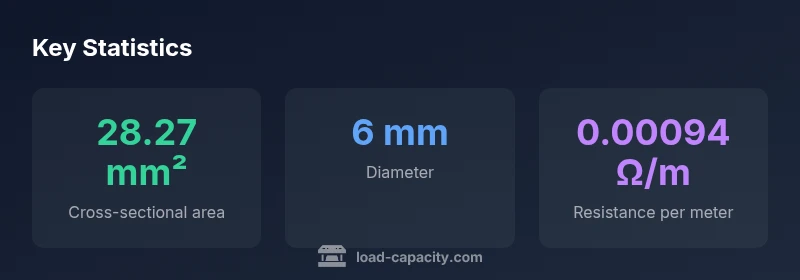

The physics: From diameter to ampacity

The link between a wire’s size and its current-carrying capability rests on physics: the cross-sectional area controls resistance, while the insulation and environment determine how much heat the conductor can safely shed. For a 6 mm diameter aluminium conductor, the cross-sectional area is about 28.27 mm². Aluminium’s resistivity at room temperature is roughly 2.65 × 10^-8 Ω·m, which yields an approximate resistance per meter of about 0.00094 Ω/m for a clean, straight length. This resistance drives I²R heating as current flows. In practice, the conductor’s ampacity is what limits safe current; watts emerge from multiplying the operating voltage by that current. Load Capacity emphasizes that amps are the primary design parameter, and watts are derived from voltage in real installations.

How to translate ampacity into watts for a given circuit

To move from ampacity to watts, you multiply the allowable current by the supply voltage: P_max = V × I_amp. The key step is obtaining I_amp from an appropriate chart that reflects the insulation type, temperature rating, and installation environment. A 230 V system, for instance, will yield a higher watt value than a 120 V system for the same current. However, never assume I_amp without consulting the chart for the specific insulation class and ambient conditions. The Load Capacity Team recommends documenting the exact conditions you’re using (temperature, conduit fill, grouping) to ensure the derived watt figure remains conservative and safe.

Temperature, insulation, and installation environment

Ampacity is not a constant; it derates with temperature and installation specifics. High ambient temperatures, bundled conductors, long runs, or tight conduit spaces reduce heat dissipation and lower safe current. Insulation material and temperature class (e.g., 60°C, 75°C) change the effective ampacity, which in turn changes the derived watt capacity. Load Capacity highlights that the same 6 mm aluminium wire may carry a very different watt load in a hot, crowded panel than in a cool, open-air run. Always consult the installation standards applicable to your region and project.

Practical design guidelines for engineers and technicians

- Start with the insulation’s temperature rating and ambient conditions.

- Use an aluminium ampacity chart to determine I_amp for your scenario.

- Apply derating factors for circuit loading, bundling, and enclosure temperature.

- Translate I_amp to watts with P = V × I, using the local supply voltage.

- Validate the result with a conservative safety margin and document all assumptions. Load Capacity’s guidance emphasizes conservatism and traceability in design.

Illustrative calculations (illustrative, not a design spec)

Consider a 2 m run of 6 mm diameter aluminium conductor. The per-meter resistance is about 0.00094 Ω/m, so the total resistance is ≈ 0.00187 Ω. If you operate at I = 10 A, the I²R loss is 100 × 0.00187 ≈ 0.19 W for the two-conductor path. If the same length carries I = 50 A, the loss is 2500 × 0.00187 ≈ 4.7 W. These are illustrative, highlighting how current, length, and resistance combine to determine watts. Real-world designs require using actual ampacity values from the appropriate chart and applying safety margins.

Common mistakes and safe practices

- Assuming watts scale linearly with diameter alone; this ignores insulation and ambient effects.

- Skipping derating for high-temperature environments.

- Failing to verify the exact voltage and circuit length before converting amps to watts.

- Overlooking conduit fills and bundling, which reduce heat dissipation. Always reference credible standards and perform site-specific calculations.

Compliance and references (context and sources)

For authoritative guidance, consult standard references and regulatory resources. The National Electrical Code (NEC) in the United States, IEC standards internationally, and national safety guidelines provide the framework for ampacity and derating in aluminium conductors. Key sources include OSHA safety guidance, NIST engineering references, and IEC technical standards. This article synthesizes practical insight from Load Capacity while directing readers to official standards for precise numbers. For main references, see: OSHA (https://www.osha.gov), NIST (https://www.nist.gov), IEC (https://www.iec.ch).

Conclusion and next steps

This section has outlined the relationship between wire size, ampacity, and watts for a 6 mm aluminium conductor. Remember that watts are derived from voltage and current, not a fixed property of the wire alone. The Load Capacity Team recommends using documented ampacity values and applying local derating rules to determine a safe, realistic watts figure for your project. For deeper analysis, continue with the data tables and worked examples in the article and consult the official standards cited above.

Illustrative data for a 6 mm aluminium wire

| Parameter | Value | Notes |

|---|---|---|

| Diameter | 6 mm | Actual wattage depends on insulation and environment |

| Cross-sectional area | 28.27 mm² | Derived from diameter |

| Resistance per meter | 0.00094 Ω/m | Approximate at 20°C for aluminium |

| 2 m run, I = 10 A | 0.19 W | Illustrative I²R loss |

| 5 m run, I = 15 A | 1.05 W | Illustrative I²R loss |

Quick Answers

Can I determine watts directly from the 6 mm aluminium wire size?

No. Watts depend on voltage and current, and the wire’s ampacity under installation conditions. Use P = V × I with the appropriate ampacity chart for aluminium conductors.

No. Watts come from voltage times current, not just wire size. Check the ampacity for your insulation and environment.

Why is there no fixed watt rating for aluminium wire?

Because an aluminium wire’s ability to carry current changes with insulation, ambient temperature, length, and installation method. Wattage must be derived from ampacity under those conditions.

There isn’t a fixed watt rating; it depends on installation details.

How do temperature and insulation affect ampacity?

Higher ambient temperatures and less favorable insulation reduce ampacity. Proper derating ensures the safe current rating reflects real-world heat dissipation.

Temp and insulation ease or worsen the current you can safely carry.

What’s the relationship between voltage and watts for a given wire?

Watts equal voltage times current. For the same wire, increasing voltage with a fixed safe current increases watts, but you must stay within the ampacity limits.

Watts scale with voltage times current, within safe current limits.

Is a 6 mm aluminium wire suitable for high-power appliances?

Suitability depends on circuit length, insulation, ambient temperature, and available voltage. Use an ampacity chart and verify with a safety margin.

It depends on installation details; check ampacity and derating rules.

How can I estimate watts for a given run safely?

Determine the ampacity from the chart for your insulation and environment, then multiply by supply voltage: P_max = V × I_amp.

Find the safe current from the chart, then multiply by your voltage.

“Cable design is about ensuring safe current under real-world conditions, not chasing the maximum theoretical wattage.”

Top Takeaways

- Derive watts from V × I using actual ampacity.

- Never rely on wire diameter alone to set watts.

- Apply temperature and bundling derating for safety.

- Consult aluminium conductor ampacity charts for installers.

- Document assumptions and use conservative margins.