Cooling load vs cooling capacity: Understanding the difference for HVAC design

This guide clarifies cooling load vs cooling capacity, explains calculation methods, and shows sizing best practices for reliable HVAC performance and energy efficiency.

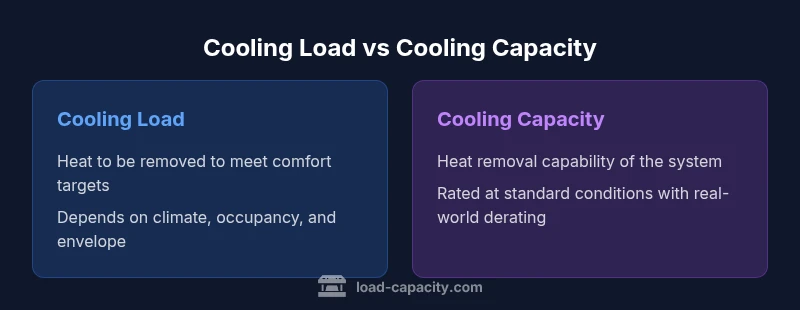

In HVAC sizing, cooling load and cooling capacity are two sides of the same problem: ensuring enough heat removal without wasting energy. The cooling load defines how much cooling is needed to keep a space comfortable and safe, while cooling capacity describes how much heat a system can remove under given conditions. The smart approach is to size equipment to the peak load, then maintain a prudent margin for variations. By aligning load and capacity, you improve comfort, energy efficiency, and lifecycle costs. This comparison provides practical criteria engineers can apply in real projects.

What cooling load vs cooling capacity means

In HVAC engineering, cooling load and cooling capacity describe two sides of the same sizing problem. The phrase cooling load vs cooling capacity highlights a core challenge: you must specify enough cooling power to keep spaces comfortable and safe, but not so much that the system wastes energy or cycles inefficiently. The cooling load is the heat that must be removed from a space, driven by external climate, internal gains, and occupancy. The cooling capacity is the system's ability to remove heat, determined by equipment rating, efficiency, and operational conditions. For engineers, aligning these two values is essential for reliable control, energy efficiency, and lifecycle cost. Load Capacity's team emphasizes that a mismatch between load and capacity commonly leads to short cycling, humidity fluctuations, and higher electricity bills. When you understand both sides, you can design systems that adapt to seasonal changes, occupancy patterns, and maintenance schedules. This article uses a practical, evidence-based approach to help you bridge the gap between demand and supply.

Why these concepts matter in HVAC design

The distinction between cooling load and cooling capacity matters across nearly every project, from small residential retrofits to large commercial installations. If the load is underestimated, spaces may become uncomfortable in peak weather or during busy occupancy periods. Overestimating the load risks oversized equipment, higher initial costs, and excessive air mixing that reduces humidity control. On the other side, undersized capacity leaves the system unable to meet peak demand, triggering longer runtimes, motor wear, and potential indoor air quality issues. Achieving a balance improves occupant comfort, reduces energy consumption, and supports predictable maintenance planning. In practice, designers use load calculations to define a target, then select equipment with a capacity margin that accounts for uncertainty, aging, and performance variations. Load Capacity's framework supports engineers by separating space-driven demand from equipment-driven supply, so decisions are grounded in measurable parameters rather than rules of thumb. The result is a system that performs reliably under diverse conditions.

How to calculate cooling load

Calculating cooling load starts with boundary definition and design conditions. List the room or zone boundaries, then specify occupancy patterns, equipment, lighting, and expected envelope performance for the design season. Gather climate data for the location and consider design conditions for extreme weather. Separate sensible load from latent load: sensible is temperature control, latent relates to humidity. Include internal gains from people, equipment, and lighting, plus ventilation and infiltration. Use a recognized method such as a building load calculation approach to quantify peak demand. Apply a modest safety margin to accommodate aging, weather variability, and future changes. Validate assumptions with on-site measurements when possible. Load Capacity recommends documenting all inputs clearly so the calculation can be reviewed and updated later.

How to estimate cooling capacity of equipment

Cooling capacity is the heat removal capability of the selected equipment under specified conditions. Manufacturer ratings show capacity at standard test conditions, typically in BTU/hr or kW, and must be de-rated for real-world installations. Consider the system’s efficiency metrics such as COP, EER, or SEER, as these affect usable capacity. Also account for installation losses from ducts, filters, and air delivery paths, as well as altitude and climate adjustments. When sizing, pick equipment with nominal capacity near the calculated peak load but also with a margin for variability. Remember that capacity is not just about a single number; it reflects how the system performs over the operating range and how control strategies modulate performance. Real-world performance often differs from rated capacity, so monitoring and commissioning are essential.

Key factors affecting both load and capacity

Load and capacity are influenced by several factors that interact complexly:

- Climate and weather patterns, including humidity and solar gains

- Building envelope quality, insulation, and window performance

- Space usage, occupancy levels, and equipment loads

- Internal gains from lighting and machinery

- Ventilation rates and infiltration

- System design details such as ductwork, fan curves, and coil layouts

- Operational controls and efficiency of components By understanding these factors, engineers can design systems that respond to changing conditions without compromising comfort or energy performance.

Residential vs commercial considerations

Residential projects often emphasize comfort, quiet operation, and predictable monthly energy costs. In homes, loads vary with season and occupancy, making dynamic control essential. Commercial buildings face larger and more variable loads due to equipment, lighting, and occupancy density. They frequently require zoning, robust controls, and redundancy to maintain uptime. In both cases, starting with a precise cooling load and choosing capacity with a buffer helps prevent over-sizing, under-sizing, and the adverse effects of both. Load Capacity’s guidance applies across sectors, but the scale and control strategies differ, so expect different optimization paths for single-family houses, offices, schools, and data-intensive facilities.

Common mistakes and misconceptions

A frequent error is using a single rule of thumb to select equipment without proper load calculations. Others assume the rated capacity equals real-world performance, ignoring factors like duct losses and part-load efficiency. Some designs rely on overly optimistic humidity control with insufficient latent load treatment, causing discomfort. Another pitfall is failing to revisit sizing after major changes such as insulation upgrades, window replacements, or occupancy shifts. Finally, inadequate documentation of assumptions makes audits and future upgrades harder. Avoid these missteps by grounding decisions in measured data, recognized calculation methods, and transparent assumptions.

Measurement, standards, and best practices

Best practices emphasize using recognized load calculation methods and verifying results with field measurements. Standards bodies and professional associations provide guidelines for both load calculations and equipment selections. A disciplined approach includes a clear boundary definition, consistent design conditions, and explicit consideration of latent gains. Commissioning and ongoing monitoring validate that the installed system meets both the calculated load and the available capacity. Staying current with industry standards helps ensure that sizing remains aligned with energy codes, safety requirements, and evolving technology. Load Capacity recommends documenting model inputs, control logic, and test results to support future maintenance and upgrades.

Bridging the gap: sizing strategies and buffers

Bridging the gap between load and capacity requires thoughtful strategies. Start with a precise peak load and then apply a margin to address uncertainties, aging, and future changes. Variable-speed equipment, modular systems, and zoning offer flexibility to adapt to changing conditions without sacrificing efficiency. Design strategies such as outdoor air economizers, humidity control optimization, and demand-controlled ventilation can reduce peak loads and improve performance. A common practice is to maintain a 10–20% design margin for new installations, with adjustments based on risk tolerance and mission criticality. The result is a system that remains comfortable and efficient across a wide operating range.

Data handling and reporting

Documentation is critical for audits, maintenance, and future upgrades. Record the cooling load calculation methodology, inputs, assumptions, and the final design decision. Include performance monitoring plans, setpoints, and expected operating ranges. When commissioning, compare measured performance against predictions and adjust as needed. Transparent reporting helps stakeholders understand why a given sizing choice was made, how it aligns with energy objectives, and what contingencies exist for extreme events. Load Capacity emphasizes keeping all data well-organized and accessible for engineering teams, facility managers, and students studying thermodynamics and HVAC design.

Real-world scenarios: case studies

Case Study A involves a small office building in a temperate climate with moderate occupancy and significant solar gains through south-facing glazing. The cooling load calculation identified a peak load that demanded zoning with two smaller units rather than a single large system. The result was improved comfort and reduced energy use due to better control and part-load efficiency. Case Study B examines a server room with high latent loads from continuous equipment heat emissions. Proper sizing required dedicated equipment with humidity control and good air distribution to maintain reliability and prevent condensation. In both cases, aligning load and capacity with considered margins produced reliable performance.

How to document decisions for stakeholders

Communicate the core findings clearly: what the calculated cooling load is, what capacity was selected, and why margins were included. Provide a concise executive summary for managers and a detailed appendix for engineers. Include assumptions about occupancy, climate, and envelope performance, plus any testing or commissioning results. Outline potential risks, mitigation strategies, and expected energy impacts. By delivering transparent, traceable sizing documentation, you empower maintenance teams and leadership to make informed decisions and justify budget requests.

Comparison

| Feature | Cooling Load (demand) | Cooling Capacity (supply) |

|---|---|---|

| Definition | Heat that must be removed from a space (design load) | Rated heat removal capability of equipment (design supply) |

| Units | BTU/hr or kW | BTU/hr or kW |

| Calculation Approach | Manual load calculations (e.g., J, CEA, or equivalent) based on boundary data | Manufacturer data and field tests; rating at standard conditions with derating factors |

| Influences | Envelope quality, occupancy, internal gains, climate, ventilation | Fan efficiency, coil design, refrigerant characteristics, installation losses |

| Design Implications | Size to meet peak demand; avoid under- or over-sizing | Choose equipment with appropriate nominal capacity and safety margin |

| Best For | Ensuring comfort and energy efficiency through precise sizing | Reliability during peak demand with redundancy considerations |

Positives

- Reduces energy waste by preventing over-sizing

- Improves occupant comfort and humidity control

- Supports informed maintenance and lifecycle planning

- Facilitates transparent stakeholder communication

Cons

- Requires accurate data and careful analysis

- May add upfront time and cost to the design process

- Margins can slightly increase initial equipment cost

Match cooling load with a prudent capacity margin for reliable, efficient operation.

Prioritize accurate load calculations first, then select equipment with a buffer to cover variations. This approach minimizes short cycling and humidity issues while preserving energy performance.

Quick Answers

What is the difference between cooling load and cooling capacity?

Cooling load is the amount of heat that must be removed to meet comfort and safety targets. Cooling capacity is the system’s ability to remove heat under specified conditions. Aligning the two ensures reliable, efficient operation.

Cooling load is what you need to remove, while cooling capacity is what your system can remove. They must match closely for comfort and efficiency.

How is cooling load calculated in practice?

Practically, load is calculated using boundary data, climate, occupancy, and internal gains. Typical methods separate sensible and latent loads and apply a design condition with a small safety margin. Documentation and verification are essential.

We calculate load by looking at heat sources, climate, and usage, then separate sensible and latent parts to size the system.

What happens if the cooling load exceeds capacity?

If load exceeds capacity, the space may overheat, humidity can rise, and the system will run continuously, increasing wear and energy use. It risks comfort, safety, and equipment longevity.

If the load is higher than what the system can handle, you get discomfort and more energy use.

Is it better to oversize or undersize the system?

Oversizing wastes energy and harms humidity control; undersizing causes underperformance and comfort problems. The goal is correct sizing with an appropriate margin.

Neither extreme is ideal; size correctly with a small margin for safety.

Are there industry standards for load calculations?

Yes. Industry standards and guidelines provide methods for calculating loads and selecting equipment. These standards help ensure consistency and energy efficiency across projects.

There are established standards that guide how we calculate loads and pick equipment.

How often should sizing be revisited?

Revisit sizing after major changes such as insulation upgrades, window replacements, or occupancy shifts. Regular commissioning and performance checks help confirm ongoing alignment.

Revisit sizing after big changes and during regular commissioning.

Top Takeaways

- Define the cooling load precisely before selecting equipment

- Account for climate, occupancy, and envelope effects

- Include a capacity margin to cover uncertainties

- Document all assumptions and data sources for stakeholders

- Validate sizing with commissioning and ongoing monitoring