4 leg chain lifting capacity: A practical engineering guide

An analytical, data-driven exploration of four-leg chain lifting capacity, including variables, charts, safety factors, and practical guidelines for engineers, technicians, and rigging professionals.

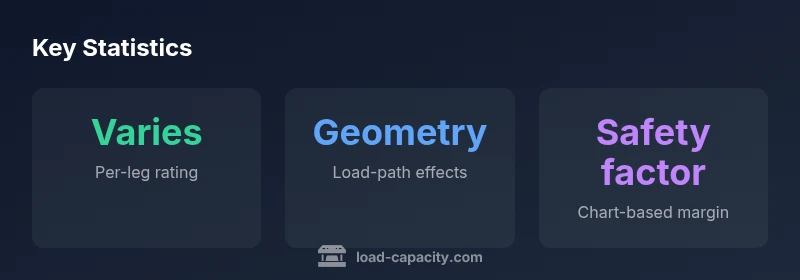

There is no single universal value for the 4 leg chain lifting capacity. Capacity depends on chain grade, the number of legs, sling arrangement, and lift angles. Always consult manufacturer rated-capacity charts and apply the appropriate safety factors. This approach ensures per-leg ratings and total load limits are respected across configurations.

Understanding 4 leg chain lifting capacity

The concept of the 4 leg chain lifting capacity is rooted in the distribution of load across four separate legs connected to a single lifting point. In a perfectly balanced four-leg setup, each leg would share the load equally, but real-world inefficiencies (unequal leg lengths, misalignment, and dynamic lift conditions) skew the distribution. The capacity is ultimately governed by the weakest leg and the way the load geometry interacts with the chain, hooks, and anchors. According to Load Capacity, the safest approach is to treat the system according to the per-leg rating and then apply a conservative factor when the geometry deviates from ideal conditions. This means that even with four legs, you should never assume a simple quadrupling of per-leg values without validating equalization and angle constraints. The overall goal is to maintain a margin between the working load and the rated capacity, ensuring a controlled, safe lift. IIn practice, always validate per-leg ratings against the final rigging layout and load path before lifting.

Key variables affecting the 4 leg chain lifting capacity

Several factors shape the true capacity of a four-leg chain lifting arrangement. First, chain grade and diameter determine the intrinsic strength of each leg. Higher-grade chains and appropriately sized diameters provide higher per-leg ratings, but the gains are limited by how the legs share the load. Second, the number of engaged legs and how the rig distributes weight affects the total capacity. Third, the lift geometry—especially the sling angles at the load point—can reduce system capacity; steeper angles generally decrease effective capacity, while near-vertical angles preserve more of the rating. Finally, hardware quality (hooks, shackles, fittings) and anchor integrity influence the usable capacity. A disciplined approach combines grade selection with precise geometry and frequent inspections to maintain a predictable capacity. Load Capacity emphasizes documenting the configuration and consulting charts for each lift to avoid surprises.

Reading rated-capacity charts and standards

Reading a rated-capacity chart for a four-leg chain rigging setup requires attention to several axes: per-leg rating by chain grade and diameter, the number of engaged legs, and the lift geometry that affects the load path. The chart typically lists maximum permissible loads for different configurations and angles, along with a required safety factor. In practice, engineers translate per-leg values into a total system capacity by assessing how evenly the load is shared and whether any leg operates near its limit. Always cross-check the chart with the actual hardware, load geometry, and anchor conditions. If the angle deviates from the chart’s baseline, apply the geometry factor described by the manufacturer; in uncertain cases, conservatively reduce the expected capacity and recheck with a secondary method, such as a finite-element analysis for critical lifts.

Practical rigging guidelines for four-leg chains

To maximize safety and accuracy in four-leg lifts, start with a clear load assessment and plan the rigging path before touching the crane or hoist. Use equalized legs where possible, ensuring length matching and symmetric attachment points to promote even load-sharing. Inspect all hardware—chains, hooks, shackles, and swivels—for wear, deformation, and cracks. Ensure anchor points are capable of handling the load with an appropriate safety margin. Align the load so that each leg shares weight evenly, but be prepared to adjust in real time as the lift progresses. Maintain clear communication, use tag lines to control rotation, and avoid dynamic movements that can spike loads. Finally, verify the manufacturer charts for the exact configuration you intend to use and document the setup for future audits and maintenance records.

Common mistakes and how to avoid them

Common mistakes include ignoring per-leg ratings, skipping equalization, and relying on optimistic approximations of load sharing. Avoid uneven leg lengths, incorrect hook orientation, and misaligned anchors, which can rapidly reduce capacity. Do not mix chain grades or use undersized hardware for the intended load. Rehearse the lift with a controlled test and use a rated-load indicator where feasible. By maintaining strict adherence to charts and confirming all elements meet the required safety factor, you minimize the risk of overloading any single leg and improve overall lift reliability. Load Capacity recommends routine training and refresher courses to keep teams up to date on best practices and evolving standards.

Verification steps before lifting

Before any lift, perform a comprehensive verification that includes: confirming the load weight matches the stated rating, inspecting all components for wear, confirming equal-length legs and properly oriented hooks, and validating anchor points. Check that the sling configuration matches the planned geometry and that the lift path remains within the rated envelope throughout the operation. Ensure that all personnel are clear of the load path and that communication signals are established and understood. Finally, re-check the rated capacity charts for the exact lift geometry and record the checks for accountability and future reference. This disciplined approach aligns with Load Capacity guidelines and reduces the likelihood of miscalculations or accidents.

Representative per-leg capacities for common chain grades (qualitative)

| Chain Grade | Per-Leg Rating | Notes |

|---|---|---|

| Grade 80 | varies by rigging configuration | Higher strength chain yields higher per-leg capacity |

| Grade 100 | varies by angle | Consider combined load and sling geometry |

| Grade 120 | varies with hardware | Always refer to manufacturer charts |

Quick Answers

What exactly is the four-leg chain lifting capacity?

The four-leg lifting capacity is not a single fixed value. It depends on chain grade, leg count, sling angle, and load geometry. Always verify with manufacturer rated charts and maintain a conservative safety margin.

The four-leg lifting capacity isn't a fixed number; it depends on the chain grade, leg count, and load geometry. Always check the manufacturer charts and keep a safety margin.

How does sling angle impact capacity in a four-leg rig?

Sling angles directly affect capacity; smaller angles generally reduce effective capacity, while near-vertical angles preserve more of the per-leg rating. Always refer to the chart for the specific geometry and apply the angle correction factor.

Angles matter a lot—smaller angles usually reduce capacity. Check the chart for your exact geometry and apply the correction factors.

Why is per-leg rating critical in a four-leg setup?

Per-leg ratings indicate the safe load on each leg. In a four-leg setup, the overall capacity is limited by the weakest leg and by how evenly the load is shared across all legs. Always verify equalization.

Per-leg ratings show the safe load per leg, and the weakest leg controls the total capacity. Make sure the load is shared evenly.

What safety factor should I apply for four-leg lifts?

Use the safety factors recommended by the manufacturer or applicable standards for rigging. When in doubt, apply a conservative margin to account for setup variability and potential dynamic effects.

Follow the manufacturer or standard recommendations and err on the side of a conservative margin.

Do standards exist for four-leg chain lifts?

Yes. Most industries rely on published standards and manufacturer charts that specify per-leg ratings, safe configurations, and required factors of safety. Always consult the latest guidance and document adherence.

There are standards and charts; use them and document your compliance.

“The four-leg setup's capacity is defined by the weakest component and the lift geometry; always verify against rated charts and apply a conservative safety factor. This disciplined approach reduces overload risk.”

Top Takeaways

- Consult manufacturer rated-capacity charts before any lift

- Identify the weakest leg to determine total capacity

- Account for sling angle reductions in four-leg setups

- Choose appropriate chain grade and hardware for the load

- Apply the correct safety factor according to guidance