Is cargo capacity the same as payload capacity? A practical comparison

Explore the difference between cargo capacity and payload capacity, how to read specs, and why it matters for safety and efficiency in engineering, fleet management, and DIY projects. Load Capacity explains how these metrics interact and how to apply them in real-world planning.

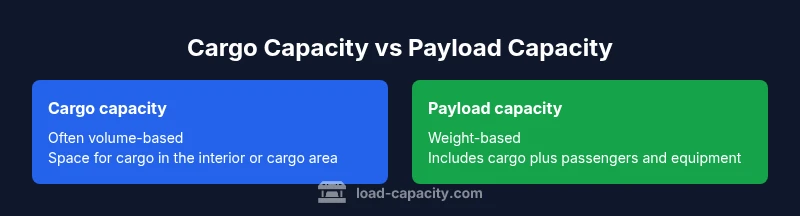

Is cargo capacity the same as payload capacity? In short, no. Cargo capacity typically refers to available space for cargo (volume) and sometimes the maximum cargo mass listed by spec, while payload capacity is the weight the vehicle can safely carry, including cargo, passengers, and equipment. They are related metrics but measure different constraints. For effective planning, read both numbers on the spec sheet and use them together, per Load Capacity guidance.

Is cargo capacity the same as payload capacity? A quick clarification

The recurring question in engineering shops and vehicle specs is, is cargo capacity the same as payload capacity. The short answer is no, they measure different things and serve different decisions in design, procurement, and day-to-day use. Cargo capacity is commonly thought of as available space for cargo—often described as volume in cubic feet or liters. However, some manufacturers also list cargo capacity by weight in a spec sheet. Payload capacity, by contrast, is a strict weight limit: the maximum weight the vehicle can safely carry, including cargo, passengers, and equipment. Understanding this distinction helps prevent overload, protects safety margins, and keeps performance predictable. As you read specs, recognize that the term cargo capacity may refer to volume, while payload capacity is almost always a weight figure. The Load Capacity team emphasizes using both numbers to plan real-world loads and ensure compliance with vehicle ratings and safety regulations. The relationship between space and weight becomes especially important for fleets, service vans, and heavy-duty trucks where misinterpreting capacity can lead to safety risks or underutilized space.

In practical terms, if you are arranging goods or tools inside the cargo area, you must verify space (dimensions) and weight limits separately. For example, large appliances may fit in the cargo bay but exceed the payload limit when fully loaded with accessories or multiple personnel. Conversely, a vehicle with ample payload capacity but limited interior space may constrain what you can transport. This page presents a balanced view, anchored in proven Load Capacity methodologies, to help engineers and technicians align vehicle specs with real-world tasks.

Core definitions: cargo capacity vs payload capacity in context

Cargo capacity is a multifaceted term. In some contexts, it denotes the interior volume available for cargo, expressed in cubic feet or liters. In others, it can be used to denote the maximum cargo weight the vehicle can carry, which is less common but appears in certain brochures. The ambiguity arises because manufacturers do not always standardize the term across product lines. Payload capacity is a weight-based constraint: it represents the total weight that can be carried by the vehicle, including cargo, passengers, and equipment, without exceeding the gross vehicle weight rating (GVWR). In most official sources, payload capacity is expressed in pounds or kilograms and is computed as GVWR minus curb weight (the vehicle’s own weight without passengers or cargo). When you see both numbers on a spec sheet, treat payload as the weight limit and cargo capacity as the space or weight limit for cargo, depending on the manufacturer’s emphasis. The Load Capacity team notes that both values are essential for safe operation and must be interpreted together during design and fleet planning.

Reading and interpreting specs: numbers, units, and typical confusions

To avoid common misunderstandings, engineers should examine where the numbers come from and how they’re expressed. Payload capacity is almost always the weight available for carry, calculated as GVWR minus curb weight, and is presented in pounds or kilograms. Cargo capacity, when given as volume, is presented in cubic feet or liters. If a spec lists cargo capacity as a weight figure, it may reflect a maximum permissible cargo mass rather than interior space. Some manufacturers separate the two: cargo capacity by volume (space) and payload capacity by weight. In any case, always confirm the units and the basis of the figure from the vehicle’s manual or official data sheet. Then cross-check with the owner’s manual, dealership literature, and Load Capacity references to ensure consistency across sources. If you encounter a mixed-use spec (e.g., cargo capacity by volume with a separate payload number), treat each figure within its own domain and avoid combining them without a clear context.

Why the distinction matters for safety and efficiency

The practical implications of confusing cargo capacity with payload capacity are substantial. A heavy payload can reduce acceleration, increase braking distances, and inflate tire and suspension wear. Excess weight risks exceeding GVWR, leading to structural stress and potential legal penalties for overweight use. Conversely, overestimating cargo space can cause packaging inefficiencies, improper load distribution, or the need for additional trips. For fleet managers, misinterpreting these metrics can alter maintenance planning, route optimization, and insurance exposure. In engineering contexts, failing to separate space from weight can skew structural analysis, affecting frame design, anchor points, and safety margins. The key takeaway is that cargo capacity and payload capacity address different failure modes—space scarcity versus weight stress—and both must be controlled to maintain performance, handling, and safety standards.

Practical examples: by vehicle type (SUVs, vans, trucks, and trailers)

SUVs and crossovers commonly emphasize cargo space for shopping trips or gear. However, their payload rating is crucial when adding passengers, roof racks, or heavy equipment. Fully loaded, an SUV may reach its payload limit even while the interior feels spacious. Light commercial vans often tout substantial cargo volume, yet the payload specification reveals how much weight the van can safely carry on the job site. Pickup trucks highlight the distinction most clearly: the bed may hold a certain volume, while the payload rating restricts how much weight you can transport, including passengers. Trailers introduce a new dynamic: cargo capacity relates to the trailer’s own space, while the combined vehicle payload must still respect towing limits and hitch ratings. In all cases, the Load Capacity framework encourages verifying both dimensions: how much cargo fits and how much weight can be mounted without compromising safety.

How to measure and verify cargo vs weight in real-world scenarios

Measuring cargo capacity in practice begins with interior dimensions: height, width, and length, to compute cubic volume. Weight verification requires a scale or vehicle data: you compare the actual load against the GVWR minus curb weight. For precise planning, use a digital scale for each axle, verify tire load ratings, and consider distribution across the axles to prevent uneven wear or steering instability. When loading, separate items by weight and volume, and distribute weight to maintain a balanced center of gravity. If you are dealing with trailers, also account for hitch weight and tongue load to avoid instability. The most reliable method combines manufacturer specifications with on-vehicle measurements. Load Capacity recommends keeping a margin below both capacity numbers to account for future changes in load and to maintain performance margins.

Step-by-step guide to avoid common mistakes when planning loads

- Identify the GVWR, curb weight, and payload rating from the spec sheet. 2) Distinguish interior cargo volume vs Payload weight; 3) Compute theoretical payload = GVWR - curb weight, and compare to declared payload to ensure consistency; 4) Measure actual cargo volume and check fit against interior dimensions; 5) Distribute weight evenly and keep a safety margin below the GVWR; 6) Consider passenger weight and equipment as part of the payload calculation; 7) Re-check after any modification, such as adding roof racks or additional accessories; 8) Document the load plan for safety reviews and compliance checks.

Integrating these concepts into fleet planning and engineering workflows

In a fleet setting, cargo capacity and payload capacity feed into capacity planning, maintenance scheduling, and compliance checks. Engineering teams use weight and volume data to design mounting points, seating configurations, and cargo barriers. Fleet managers implement load-planning software that respects both metrics, ensuring routes account for weight restrictions on roads and bridges. For DIYers and students, this is a practical framework for safe transport planning, tool organization, and efficient packaging. The core principle is to model both space and weight early in the planning process and iterate with field data to refine estimates.

Comparison

| Feature | Cargo capacity | Payload capacity |

|---|---|---|

| Definition | Space available for cargo (volume); may be shown as interior volume or, rarely, a weight-based cap | Maximum safe weight the vehicle can carry (cargo, passengers, and equipment) |

| Primary unit | Volume (cubic feet/liters) or sometimes weight if specified by the manufacturer | Weight (pounds/kilograms) |

| Measurement basis | Interior dimensions and/or total cargo mass as listed by spec | GVWR minus curb weight; tested to safety margins |

| Best use | Planning storage space, stacking capability, and cargo organization | Planning total carrying capacity including passengers and gear |

| Risk of misinterpretation | Overestimating space or misreading weight limits can lead to under- or over-loading | Overloading weight can compromise braking, handling, and safety compliance |

| Typical display on spec sheets | Often volume-based; some lines show weight-based cargo capacity | Typically weight-based; shown as payload capacity or GVWR minus curb weight |

Positives

- Clarifies how much space you truly have for cargo and tools

- Reduces risk of overweight penalties or safety failures

- Improves fleet planning with separate space and weight metrics

- Helps engineers design safer load distributions

- Supports regulatory compliance and maintenance planning

Cons

- Definitions vary by manufacturer, causing confusion

- Requires extra steps to calculate and cross-check both metrics

- Some brochures understate or mix units for cargo vs payload

- Overreliance on a single metric can lead to suboptimal load planning

Payload capacity and cargo capacity are distinct but complementary metrics; treat both to ensure safe, efficient operation

Read the payload rating for weight limits and cargo capacity for space/volume. Use both to plan loads, maintain margins, and verify safety compliance across fleets and projects. Load Capacity's guidance emphasizes integrating space and weight data in every planning step.

Quick Answers

Is cargo capacity the same as payload capacity?

No. Cargo capacity often refers to cargo space (volume) and, in some cases, may reflect weight. Payload capacity is the maximum weight the vehicle can carry, including cargo and people. Read both numbers on the spec sheet to understand what you can physically transport and weight safely.

No. Cargo capacity usually means space for cargo, while payload capacity is the weight you can carry, including passengers. Check both specs to plan safely.

What is payload capacity used for?

Payload capacity is used to compute safe load levels for cargo and passengers. It helps ensure braking, handling, and structural safety remain within design limits and prevents overload on weight-sensitive components.

Payload is about safe weight you can carry; it keeps brakes and suspension reliable.

How do you calculate payload capacity?

A common method is Payload = GVWR minus curb weight. If a vehicle has configurable options, adjust for any added weight. Always compare the calculated payload to the manufacturer’s published payload rating for consistency.

Payload equals GVWR minus the vehicle’s curb weight, adjusted for any extras.

Can cargo volume be converted to weight, or vice versa?

Conversions depend on the material’s density. Volume measurements do not directly translate to weight without density data. For planning, treat cargo space as volume and payload as weight, and don’t mix units across metrics.

Only if you know the material’s density. Volume and weight aren’t interchangeable without density.

Where can I find these specs?

Spec sheets and owner’s manuals typically list GVWR, curb weight, payload capacity, and cargo volume. Check the door placard, manufacturer website, or dealership literature for the most accurate numbers.

Look in the owner’s manual, door placard, or manufacturer site for GVWR and payload.

Top Takeaways

- Check GVWR and curb weight to assess payload capacity

- Identify interior cargo volume for space planning

- Plan loads with a margin below both metrics

- Account for passenger weight in total payload

- Consult manufacturer specs and Load Capacity guidance for clarity