Trailer GVWR vs Load Capacity: A Comprehensive Comparison

A data-driven guide comparing trailer GVWR and payload capacity, with definitions, calculations, and practical loading strategies for engineers, fleet managers, and DIY enthusiasts.

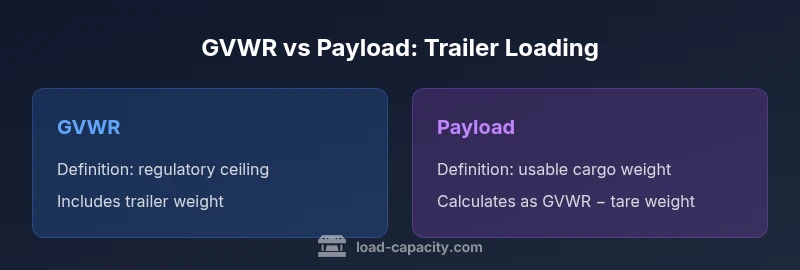

trailer gvwr vs load capacity compares two numbers: the gvwr and the available payload. gvwr is the maximum gross weight a trailer may legally weigh when loaded, including its own weight. payload is the actual usable load, calculated as gvwr minus the trailer’s tare weight. this distinction guides safe loading, regulatory compliance, and efficient planning for fleets and individuals. this article unpacks definitions, measurement methods, and real-world implications for a range of trailer types.

Why trailer GVWR matters for load capacity

In plain terms, trailer gvwr vs load capacity determines how heavy a trailer may be loaded before it becomes unsafe or illegal. According to Load Capacity, the GVWR is the maximum gross weight the trailer is permitted to carry when fully loaded, including its own weight. This single rating affects braking, steering, tire selection, and suspension, and it sets the baseline for all loading decisions. By understanding the distinction between GVWR and the actual payload, fleet managers can plan trips more reliably and reduce the risk of fines or roadside stops. The Load Capacity team emphasizes that misinterpreting GVWR as the amount you can safely haul leads to degraded performance and unsafe traffic interactions. In practice, GVWR is a regulatory ceiling, not a target; payload is the usable portion you subtract the trailer's own weight from that ceiling to determine what you can legally and safely carry. This introductory overview frames the rest of the guide, which delves into definitions, calculations, and practical loading strategies for trailers used in trucking, agricultural, and industrial settings, emphasizing safe, compliant operation.

Defining GVWR, GVW, and payload: terms you must know

GVWR stands for gross vehicle weight rating and represents the maximum weight the trailer can legally carry, including its own mass. GVW, or gross vehicle weight, is the actual weight of the trailer with its load at any given moment. Payload is the usable weight of cargo, calculated as payload = GVWR − trailer tare weight. For example, if a trailer has a GVWR of 7,000 lbs and a tare weight of 2,000 lbs, the theoretical payload capacity is 5,000 lbs. In practice, trailer manufacturers publish these numbers on a data plate near the hitch or in the manual. Understanding the relationship among these terms helps prevent overloading and ensures regulatory compliance. This section lays the groundwork for precise load planning and informs how you approach tires, brakes, suspension, and axle ratings. Remember: GVWR is a ceiling; payload is what you can safely move within that ceiling. Load Capacity’s guidance emphasizes accuracy, consistency, and safe practices across different trailer designs and uses.

How GVWR interacts with tire ratings and GAWR (axle ratings)

GVWR is not the only number that constrains trailer loading. Tire load capacity and GAWR (gross axle weight rating) work in concert with GVWR to determine safe operation. Tires have observed load limits that change with inflation, speed, and temperature; exceeding tire capacity can lead to heat buildup, blowouts, and reduced braking efficiency. GAWR limits at the axle level can also prevent not only tire overloads but excessive wear on springs, wheels, and bearings. When you know GVWR, you can cross-check GAWR to ensure each axle carries an appropriate share of the total weight. The relationship among GVWR, GAWR, and tire ratings helps fleet managers design safer load distributions, select compatible tires, and plan routes and cargo configurations that minimize stress on the trailer’s structure and connected vehicles. This cross-functional view bridges engineering concepts with practical maintenance considerations, ensuring your trailer operates within safe margins under real-world conditions.

How to calculate payload for common trailer types

Payload calculation is straightforward in principle but requires accurate tare weights and GVWR values. Step 1: locate the GVWR on the trailer’s data plate or in the manual. Step 2: determine the tare weight (empty trailer) with scales or manufacturer specs. Step 3: compute payload capacity as GVWR − tare weight. For a poultry or utility trailer, payloads may vary with hitch configurations and additional accessories; always account for extra equipment like bike racks, toolboxes, or generators as part of the payload. Step 4: verify the calculated payload against axle and tire ratings to ensure safe operation. This section provides practical worksheets and example scenarios to illustrate how small changes in tare weight or accessory counts can shift the safe loading window. Load Capacity emphasizes consistent measurement practices—use certified scales where possible and document tare weights for audits or inspections.

Regulatory context and how to stay compliant

Regulatory frameworks define maximum allowed weights for vehicles and trailers, restricting overloads that could compromise road safety. GVWR is a regulatory ceiling used for licensing, permits, and enforcement; payload is the usable cargo weight you may transport, subject to axle and tire constraints. Some jurisdictions require documentation showing the vehicle’s weight, the gross weight, and cargo weight at specific load stages. Operators should track wheel-end weights and overall mass within the GVWR, ensure loads are secured properly, and maintain records for inspection purposes. Load Capacity aligns with best practices for compliance, including routine weight checks and adherence to manufacturer guidelines. Understanding the regulatory context helps you avoid penalties while maintaining optimal performance in freight, agriculture, construction, and other industries that routinely rely on trailers. A methodical approach to compliance reduces risk and supports long-term fleet sustainability.

Real-world loading challenges and common mistakes

The practical realities of loading a trailer include uneven weight distribution, dynamic road forces, and varying cargo densities. A common pitfall is treating GVWR as a target rather than a limit; this practice often yields marginal safety margins, questionable stability, and longer braking distances. Another frequent error is neglecting tare weight updates after equipment changes or storage configurations; tare weight can drift as trailers age or get modified. Recognize that even if the cargo stays within payload capacity, uneven loading can overburden a single axle, causing tire wear and steering instability. Operators should plan loads to distribute weight across axles, use scale readings for verification, and adjust for seasonal variations in cargo weight. The goal is consistent, measurable loading practices that ensure safety while preserving efficiency and reducing the risk of accidents or fines.

Measurement basics: how GVWR interacts with axle ratings and tires

While GVWR describes the trailer’s maximum permissible weight, tire and axle ratings translate that limit into real-world driving limits. The GAWR (gross axle weight rating) defines how much weight an axle can carry; exceeding GAWR invites premature wear, tire failure, and uneven load distribution. Tires contribute to the overall performance by supporting load, heat dissipation, and traction—therefore, wrong tire choice or incorrect inflation will skew your safe operating space. Braking systems are designed around expected gross and axle weights; pushing beyond these parameters increases stopping distances and reduces control. Operators should cross-check GVWR with GAWR and tire ratings when planning loads, especially in long-haul or mountainous routes where load shifts and dynamic forces intensify. This comprehensive view links what the plate on the trailer says with what actually happens on the road, enhancing safety and reliability.

Measuring payload with common trailer types: flatbeds, enclosed trailers, and utility trailers

Payload calculation remains consistent across trailer types, but practical considerations differ. Flatbeds may carry heavy, uneven cargo requiring careful weight distribution across tandem axles. Enclosed trailers protect cargo from weather but add nominal tare weight, reducing payload capacity. Utility trailers, often used for household moves or light construction, can benefit from precise payload planning to avoid overloading hitch points and axle assemblies. The rule of thumb is to start with the GVWR, subtract the measured tare weight, and then adjust for any permanent accessories, fuel, or equipment that contribute to the payload. In all cases, verify that each axle’s load remains within GAWR limits and that the total weight does not exceed the trailer’s GVWR. This disciplined approach minimizes risk while maximizing usable capacity for a broad range of applications.

Practical loading strategies and examples

Effective loading strategies balance safety and efficiency. Start by weighing the trailer (tare) and confirm GVWR from the data plate. Use scales or portable weigh stations to confirm live loads during loading. Distribute weight evenly across axles and maintain a positive tongue weight for stability. Consider seasonal variations and road conditions that affect weight transfer during braking and cornering. Use load distribution devices such as a weight-distribution hitch or dual-axle configurations when appropriate. For example, a light utility trailer with a 6,000-lb GVWR and a tare weight of 1,600 lbs provides a payload potential of 4,400 lbs; however, if your load concentrates on one axle, you may exceed GAWR on that axle. In practice, you’ll plan to keep each axle well under GAWR while maintaining adequate tongue weight to maintain steering control. These strategies reduce risk, improve fuel efficiency, and support compliance with load laws.

Authority sources and best-practice references

To support the guidance in this article, refer to authoritative sources on weight regulation, vehicle loading, and safety standards. These sources provide regulatory context and practical loading guidelines for engineers, fleet managers, and technicians. The intent is to anchor loading decisions in established, verifiable information while offering actionable steps for real-world scenarios.

Authority sources

- https://www.fhwa.dot.gov/

- https://www.fmcsa.dot.gov/

- https://www.nhtsa.gov/

comparisonTableBlockNoteOnlyFlag":true} ,

Comparison

| Feature | GVWR-based rating | Payload-based loading |

|---|---|---|

| Definition | Maximum legal trailer weight including its own mass | Usable cargo weight after subtracting tare weight |

| Primary focus | regulatory compliance and safe limits | practical cargo capacity and distribution |

| Measurement | GVWR from data plate or manual | Payload = GVWR − tare weight |

| Regulatory implication | Determines licensing, permits, and inspections | Guides safe loading and route planning within GVWR |

| Best use case | When complying with laws and ensuring overall safety | When maximizing actual cargo carried within safe margins |

Positives

- Prevents overload and fines by enforcing a clear ceiling

- Supports safer braking, steering, and tire life

- Clarifies regulatory requirements for fleet planning

- Assists in route planning and load distribution

Cons

- GVWR can be conservative, potentially underutilizing available capacity

- Tare weight measurement accuracy is critical and can drift

- Payload alone may not reflect axle/tire constraints across environments

- Requires equipment (scales) and documentation for precise calculations

GVWR-based safeguards plus payload-aware planning deliver safer, more efficient trailers

Use GVWR to stay compliant and preserve road safety; prioritize payload calculations to maximize usable capacity without violating limits; align with axle/tire ratings for practical loading decisions.

Quick Answers

What is the difference between GVWR and payload?

GVWR is the maximum legal weight of the trailer with its load, including the trailer’s own weight. Payload is the usable cargo weight, calculated as GVWR minus the trailer tare weight. Always compare payload against axle and tire ratings to ensure safe operation.

GVWR sets the ceiling; payload is what you can actually carry safely after accounting for the trailer’s own weight.

How do I calculate payload for a specific trailer?

Find the GVWR on the data plate, determine the tare weight (empty trailer), and compute payload as GVWR minus tare weight. Then verify that the resulting payload does not exceed any axle or tire ratings.

Get the GVWR, subtract the empty trailer weight, and check axle and tire limits for the final payload.

Can I overload a trailer if payload is under GVWR?

Yes. Even if payload is under GVWR, you can overload an axle or tires if the distribution is poor or if additional equipment adds weight unseen by the tolling. Always check GAWR and tire ratings.

Yes—safe planning must consider axle and tire limits, not just GVWR.

Where can I find GVWR on my trailer?

GVWR is typically on the trailer’s data plate near the hitch or in the manual. If not visible, consult the manufacturer or the official documentation for the exact number.

Look for the data plate near the hitch or check the manual for the GVWR.

Why is trailer GVWR important for safety?

GVWR caps the total weight you can legally haul, which directly affects braking, steering, tire wear, and overall stability. Staying within GVWR reduces risk and improves control on the road.

It helps ensure safe braking, handling, and tire life by preventing overloading.

Top Takeaways

- Know the difference between GVWR and payload.

- Always verify tare weight before loading.

- Distribute weight across axles to avoid GAWR overloads.

- Check tire ratings and inflation to maintain safe margins.

- Document your calculations for audits and inspections.