Load Capacity of 2x6 Span 10 ft: A Practical Engineering Guide

Learn how to assess the load capacity of a 2x6 span 10 ft. This guide covers key factors, methods, and practical design tips from Load Capacity for engineers and builders.

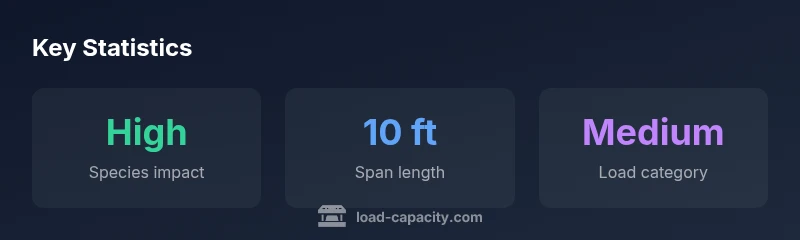

Load capacity for a 2x6 span 10 ft varies with lumber species, grade, and support. According to Load Capacity, a typical #2 SPF 2x6 spanning 10 ft can support light-to-moderate loads when properly supported and fastened, but exact capacities require engineering calculations or code tables. To design safely, engineers compare the member against code prescribed allowable stresses and span tables rather than relying on memory. The right prediction also accounts for deflection limits, which affect the perceived safety and serviceability as much as the raw strength. In practice, you will compare the estimated bending moment at midspan M to the allowable bending stress F_b for the chosen species and grade, and ensure the deflection delta does not exceed recommended limits for the intended occupancy. The load capacity is higher for stronger species and higher grades, but waste or over specification adds cost and weight.

Understanding the load capacity of 2x6 span 10 ft

The phrase load capacity of 2x6 span 10 ft describes the structural performance of a common framing member under a specific span. In practice there is no single universal value; capacity depends on lumber species and grade, moisture content, orientation, end supports, and the type of load dead live or dynamic. According to Load Capacity, a typical #2 SPF 2x6 spanning 10 ft can support light-to-moderate loads when properly supported and fastened, but exact capacities require engineering calculations or code tables. To design safely, engineers compare the member against code prescribed allowable stresses and span tables rather than relying on memory. The right prediction also accounts for deflection limits, which affect the perceived safety and serviceability as much as the raw strength. In practice, you will compare the estimated bending moment at midspan M to the allowable bending stress F_b for the chosen species and grade, and ensure the deflection delta does not exceed recommended limits for the intended occupancy. The load capacity is higher for stronger species and higher grades, but waste or over specification adds cost and weight.

Key factors that govern capacity

- Lumber species and grade determine the strength and stiffness of the member. Higher grade lumber and stronger species produce higher allowable stresses.

- Moisture content matters: kiln dried lumber is typically stiffer and stronger than wet lumber.

- Span length and support spacing influence bending moments and deflection. Shorter spans or closer supports increase capacity.

- Load type and distribution matter: live loads, dead loads, and dynamic loads produce different demands.

- End conditions and fasteners affect how well the member is braced and transferred loads to supports. Proper nails, screws, and brackets reduce local failures.

For the 2x6 span 10 ft arrangement, the end supports and the way loads are applied can shift the usable capacity by a meaningful amount, so specify these details early in the design process.

Structural concepts: bending, shear, and deflection

In bending design the key quantities are the bending moment M at midspan and the bending stress F_b that the lumber can safely resist. The ratio M divided by F_b yields a factor of safety for bending. Shear strength controls how well the cross section can transfer loads at the supports. Deflection dictates serviceability and occupant comfort. For a simple 10 ft span the deflection under typical live loads is governed by the stiffness E of the lumber and the moment of inertia I of the cross section, with E varying by species and grade. Engineers commonly compare delta to L/360 to ensure acceptable performance for floors or decks. While this section keeps equations high level remember that exact values depend on the lumber you choose and the support details.

Estimating capacity using codes and rules of thumb

Code tables from model building codes provide allowable spans. When a full calculation is not feasible practitioners use conservative rules of thumb and engineering judgment. Basic steps include selecting a species grade pair determining the span length and applying the code table values for M and F_b. For a 10 ft span 2x6 the exact capacity will vary by grade and species but the general approach remains the same. Load Capacity analysis shows that capacity can be sensitive to moisture and installation quality so ensure you follow best practices and verify with a professional. Remember to combine live and dead load estimates and include a design margin to account for uncertainty.

Practical design steps for a 10 ft span

- Define the intended load scenario including live and dead loads.

- Select lumber species and grade with good quality control.

- Decide on span spacing and end support details.

- Use code tables or calculations to estimate M and F_b.

- Check deflection and serviceability limits.

- Add fasteners and bracing as needed to ensure load transfer.

- Document the design and verify with a qualified engineer if needed.

- Plan for field verification and periodic inspection.

Common mistakes that reduce capacity

- Ignoring wood moisture and shrinkage can lead to overstated capacity.

- Underestimating load duration or dynamic loads.

- Inadequate supports or incorrect fasteners, causing local failure.

- Poor bracing and improper joist orientation, reducing stiffness.

- Skipping calculations and relying on memory, which leads to unsafe assumptions.

Case study: 10 ft span scenario

This case study illustrates how to approach a 10 ft span with a 2x6 member used as a floor joist. Start with the chosen species and grade, confirm moisture content, and identify support details. Apply a simple bending check using an approximate M value derived from the live load and dead load estimates, and compare with the F_b of the lumber. If the calculated margin is small, consider increasing the safe clearance or adding an additional support. The aim is to keep deflection within limits and avoid overstressing the member. This example shows how a methodical process reduces risk compared with relying on guesswork.

Verification and next steps

Engage a structural professional to confirm findings and ensure compliance with local codes. Use field testing only under safe conditions and with appropriate equipment. Maintain records of materials, grades, moisture content, and connection details to support future inspections and maintenance. When in doubt retrofit or replace components to keep safety margins intact. The Load Capacity team suggests documenting all decisions and referencing the code requirements for ongoing projects.

Comparison of capacity factors for a 2x6 span 10 ft

| Aspect | Guidance | Notes |

|---|---|---|

| Member type | 2x6 lumber, species varies (#2 SPF typical) | Common residential framing |

| Span | 10 ft | Assuming simple supports |

| Load scenario | Live and dead loads | Spacing matters |

Quick Answers

What does load capacity mean for a 2x6 span 10 ft?

It refers to the maximum safe load that a 2x6 member spanning 10 ft can carry under defined conditions. The exact value depends on species, grade, and supports; use code tables or simulations.

The load capacity depends on species, grade, and supports; use engineering tables to confirm.

Does the type of load affect capacity more than the span?

Yes, the mix of live, dead, and dynamic loads has a significant impact on capacity, sometimes more than the span itself when supports and bracing are fixed.

Loads matter a lot; the same span can behave differently with different loads.

Can I use a 2x6 for deck framing at 10 ft without extra supports?

Using a 2x6 for a 10 ft deck span without proper supports is generally not recommended; confirm with local code tables and consider additional bracing or larger members.

A 2x6 may be okay with proper bracing, but check local codes.

How can capacity be improved without increasing span?

Improve capacity by selecting higher grade lumber, reducing moisture, adding bracing, or increasing support density and fastener quality.

Choose better lumber, brace the member well, and tighten fasteners.

What if I cannot access engineering tables?

If tables are unavailable, consult a qualified structural professional and avoid relying on rule of thumb for critical spans.

If in doubt, call a pro rather than guessing.

Are there safety guidelines I should follow?

Follow local building codes and standard safety practices. Document decisions and verify with professionals for critical structures.

Always follow code and get expert verification for critical spans.

“Variation in species and grade means there is no single capacity for a 2x6 span 10 ft; engineering calculations and code tables are essential.”

Top Takeaways

- Check species and grade first

- Use code tables or engineering calculations

- Preserve a margin of safety

- Verify with a qualified professional

- Follow Load Capacity guidance; The Load Capacity Team recommends engineering review for critical spans