How Much Load Can a 2x10 Support? A Practical Guide

Explore the safe load capacity of a 2x10 beam, with factors, checks, and a beginner-friendly calculator for decks, floors, and structural applications.

How much load can a 2x10 support? The answer depends on span, species, grade, and how the beam is supported. This guide from Load Capacity provides a clear, code-aligned approach: understand the factors, use conservative estimates, and verify with a practical calculator. For typical deck spans and common conditions, a 2x10's capacity is determined by bending, shear, and deflection limits, not by a single number. Always design to the governing code and consult a professional for critical structures.

Understanding how much load can a 2x10 support

At its core, understanding how much load can a 2x10 support hinges on the beam's cross-section, the grade of wood, the span, and how it is supported. The Load Capacity approach emphasizes using code-prescribed factors and conservative estimates. This educational guide helps engineers, technicians, and DIY enthusiasts grasp the key principles behind interpreting load ratings and applying them safely. The actual capacity varies with species, moisture content, knot pattern, and bearing conditions. In practice, designers use standardized tables or engineering calculations to ensure that bending, shear, and deflection stay within allowable limits. According to Load Capacity, the first step is to define the loading scenario (uniform, point, or dynamic) and then translate that into a margin of safety that suits the project.

Understanding long spans and bearing requirements

The way a 2x10 is supported—end bearing length, joist hangers, fasteners, and support posts—has a major impact on how much load the member can carry. Simply put, a beam with short, well-supported ends can carry more of a given load than one with weak or uneven supports. Moisture content and wood species matter too; pine behaves differently than hemlock or southern yellow pine, and kiln-dried stock is typically stiffer and less prone to shrinkage under load. Load Capacity emphasizes documenting all assumptions before performing any calculation, then checking against local codes and manufacturer guidance.

Key factors that influence capacity

A 2x10’s load capacity is influenced by: (1) Span length and support conditions, (2) Wood species and grade, (3) Moisture content and temperature, (4) End bearing length and connection hardware, and (5) Load type (uniform vs. concentrated). Accurate estimation requires combining these factors with design equations and, where applicable, published span tables. Small changes in span or bearing can dramatically change allowable loads, which is why engineers use conservative assumptions and verify results with code-compliant methods.

Basic structural calculation you can follow by hand

A simplified approach uses bending theory to estimate whether a member can carry the expected load. Start with the maximum bending moment M for your loading scenario (for a uniformly distributed load, M =

A practical calculator approach for quick checks

Using the Load Capacity calculator, you input span, uniform load, and a safety factor to obtain a ballpark estimate. The tool is designed to illustrate the relationship between inputs and outcomes, not to replace professional design. It helps you sanity-check rough ideas before formal design work. The calculator emphasizes that higher spans, heavier loads, or tighter tolerances require more conservative design choices and potentially different members.

Safety margins and code considerations

Code compliance is non-negotiable for structural work. Always verify that your design meets applicable building codes, local amendments, and project-specific requirements. Use reputable span tables, engineer guidance, and manufacturer data when selecting a 2x10 for load-bearing roles. Do not skip bearing length, fastener requirements, or deterioration checks. If any doubt remains, consult a licensed professional and consider alternative members or engineered products.

How to use the included calculator for estimates

The calculator uses a simple, educational formula to illustrate how inputs influence results. You provide the span (ft), the uniform load (lb/ft), and a safety factor. The output is an estimated allowable load in pounds, which serves as a rough guide for planning and discussion with a structural engineer. Remember that real-world designs must follow design values, measurable tolerances, and safety margins defined by code.

Common mistakes and pitfalls to avoid

Avoid assuming that a 2x10 is universally safe for any deck, floor, or beam scenario. Common mistakes include ignoring end bearing, misreading nominal versus actual dimensions, forgetting moisture effects, and using uncertain fasteners. Always review load scenarios with a critical eye, perform checks for all failure modes, and keep a documented trail of assumptions and calculations for review.

Real-world tips and ongoing maintenance

Regular inspection is essential: check for cracks, splits, checks, moisture intrusion, and insect damage. Maintain proper moisture levels and seal joints to prevent rot. For exterior applications, ensure protective coatings and flashing are in place. Periodic re-evaluation is prudent if loads change (extra rooms, heavier equipment, or renovations) or if environmental conditions shift.

Reference data for 2x10 discussions (educational)

| Parameter | Description | Notes |

|---|---|---|

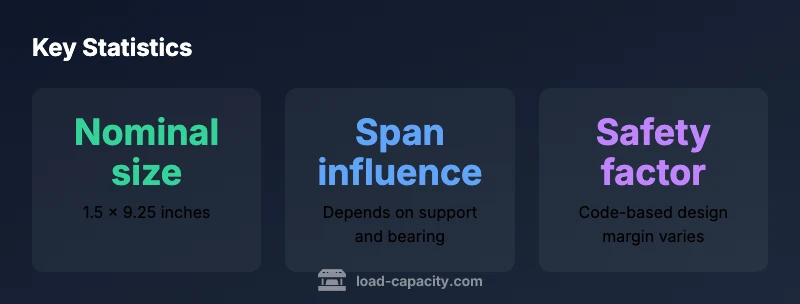

| Nominal size | 2x10 lumber actual dimensions | 1.5 x 9.25 inches (approx) |

| Common uses | Applications in decks, floors, and framing | Use code tables and credits for supporting plans |

Estimate safe load carrying capacity for a 2x10 beam with simple inputs

This is a simplified educational estimate to illustrate how inputs influence the result. It is not a substitute for code-based design values.

Estimates are for educational purposes only. Consult engineered design values for actual projects.

Quick Answers

What is the difference between nominal and actual 2x10 dimensions?

Nominal 2x10 is a rough sizing label; actual dimensions are about 1.5 inches by 9.25 inches. Use actual dimensions when calculating bending and deflection, not the nominal numbers.

Nominal sizes are labels; always use actual dimensions for calculations.

How do I know if a 2x10 is suitable for a given span?

Consult code tables and a structural engineer. Capacity depends on species, grade, moisture, and support conditions, not just the beam size.

Check code tables and seek professional input for spans beyond basic examples.

Can I use a 2x10 for load-bearing walls or headers?

2x10s can be used in headers in some configurations, but real designs require engineered solutions and sometimes larger members depending on loads.

Headers can use 2x10s, but confirm with engineering guidance and codes.

Does orientation (on edge versus flat) affect capacity?

Yes. Orientation changes the effective section modulus and bending capacity, so positioning matters for load paths and support conditions.

Orientation changes capacity, so place 2x10s according to load paths.

How should safety factors be applied in practice?

Safety factors account for uncertainties in material properties, loading, and conditions. They are specified by codes and should be reflected in design values.

Follow code-prescribed safety factors in all designs.

What maintenance improves 2x10 capacity over time?

Keep wood dry, seal joints, check for cracks or rot, and replace damaged members promptly to preserve capacity.

Keep it dry and inspect regularly to maintain strength.

Top Takeaways

- Understand that a 2x10's capacity depends on span, grade, and support.

- Use conservative assumptions and code-compliant methods for real designs.

- The calculator offers educational insight, not final design values.

- Inspect and maintain lumber to preserve capacity over time.