2x10 Load Capacity: A Practical Engineering Guide

Data-driven guide to 2x10 load capacity for wood framing and decks. Learn nominal vs actual sizes, span considerations, moisture effects, and practical rules for safe, code-compliant design.

Understanding the concept of 2x10 load capacity and its scope

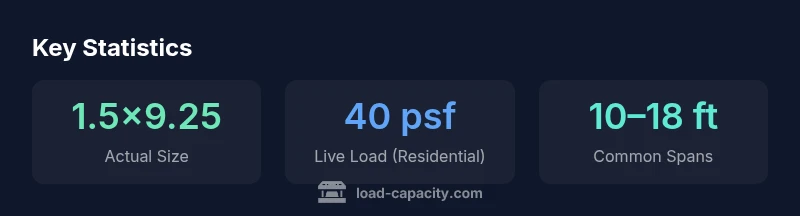

The term 2x10 load capacity is a design concept used by builders, engineers, and designers to describe how much weight a 2x10 member can safely carry in a given configuration. In practice, the concept covers bending strength, shear capacity, and serviceability limits under both live loads (people, furniture, occupants) and dead loads (the weight of the structure, sheathing, and fixed components). The keyword 2x10 load capacity surfaces in designs for floor joists, deck framing, and headers because this size is a workhorse member in many light- to mid-load applications. The actual performance depends on species (for example pine, spruce, fir), grade (such as #2 or #1), moisture content, and how the member is supported. Because nominal sizes are historical conventions, engineers convert them to actual dimensions (1.5 inches by 9.25 inches) when calculating span and load. As you plan a project, always start from a conservative load path and verify with codes and tables. According to Load Capacity, 2026, these variables frame the safe operating envelope for 2x10 members.

Key variables that influence 2x10 load capacity

Several interrelated factors determine how much load a 2x10 member can safely carry. Species and grade are primary: denser woods and higher grades offer greater strength, while more modest grades require tighter controls on span and load. Moisture content matters because wood swells and loses stiffness when wet, reducing bending strength and increasing deflection. The span and support conditions define a beam’s moment capacity and shear distribution; longer spans require stiffer members and fewer midspan deflections. Load type also matters: a uniform live load presents differently than point loads at walls or posts. Finally, the way a member is connected—proper nailing, bolts, hangers, and bearing surfaces—affects actual capacity by preventing failures at joints and reducing localized stresses. In practice, designers use these variables together with published tables and engineering formulas to estimate safe loads for each application. Load Capacity’s guidance for 2026 emphasizes the importance of treating 2x10 load capacity as a function of context, not a single number.

Nominal vs actual size and the impact on capacity

Two common sources of confusion in 2x10 load capacity are nominal sizing and actual cross-section. A nominal 2x10 measures 2 inches by 10 inches on the rough lumber, but the actual cross-section is typically 1.5 inches by 9.25 inches after planing. That seemingly small difference has a meaningful impact on bending strength, deflection, and allowable spans. When engineers perform calculations, they convert the nominal size to its actual dimensions and factor in species, grade, and moisture content. In many code-approved designs, “2x10” is treated as a starting point, not a final specification. Tolerances, rounding, and installation conditions can shift capacity by noticeable margins, so always check the exact member dimensions from your supplier and cross-check with code-prescribed tables.

Spans, deflection, and load distribution

Span length directly governs bending moment and deflection in a 2x10 beam or joist. Longer spans increase the bending moment for the same load, meaning the member must be stronger or additional supports added. Deflection limits are critical for serviceability; excessive sag can cause cracking and occupant discomfort. Load distribution matters: uniform loads over a continuous beam behave differently than point loads at ends or concentrated loads from heavy appliances. For typical light-frame construction, designers select a spacing and a span that balance stiffness, weight, and material cost. The result is a load capacity that is not a single number but a safe range dependent on the exact configuration, species, and grade. Always verify spans with published tables and verify with a qualified engineer for unusual layouts.

Design approaches: from rule-of-thumb to engineering calculations

Most practitioners start with pragmatic rules-of-thumb, such as “2x10s can span about X feet at Y spacing for a given load” based on local experience. However, precise load capacity requires engineering calculations that incorporate bending stress (fb), section modulus, shear capacity, and deflection criteria per the National Design Specification (NDS) and relevant building codes. In small-scale projects, calculators and manufacturer tables provide quick estimates; for critical structures such as multi-story floors or heavy decks, a licensed professional should verify the design. A conservative approach also means accounting for moisture changes between construction and in-service conditions and planning for future loads (furniture, appliances, potential renovations). Load Capacity’s 2026 perspective highlights the value of blending practical rules with formal calculations to ensure safety and compliance.

Real-world scenarios: floors, decks, and headers

In residential floors, 2x10 members commonly serve as floor joists subject to a 40 psf live load plus a dead-load component. In decks, the same members may carry a different ratio of live load depending on anticipated use and local snow or wind loads. Headers built from 2x10s must perform under concentrated loads from openings and structural connections. In all cases, the capacity is constrained by the weakest link: the species-and-grade of the wood, the moisture content at installation, and the accuracy of the bearing surfaces. Proper fasteners and hanger hardware help realize the design capacity and prevent joint failures. Always align 2x10 members with appropriate supports, ensure bearing surfaces are clean and flat, and avoid overloading with incompatible fasteners. These practices improve safety and structural integrity.

Codes, standards, and when to consult a professional

Code-based design for 2x10 load capacity typically references the National Design Specification for Wood (NDS) and regional building codes (IRC/IBC) that govern allowable spans, live loads, and deflection limits. Because local climate, use-case, and installation details vary, confirm your approach with architectural drawings and a qualified structural engineer where required. The Load Capacity team urges engineers and technicians to document assumptions, check moisture content, and consider future modifications to the structure. For critical projects, obtain permits and have calculations reviewed to ensure compliance with safety standards and code requirements. Always rely on credible references and industry guidelines rather than informal estimates.

Maintenance, moisture control, and safety considerations

Wood is a living material whose properties shift with moisture and time. Regular inspection for signs of swelling, warp, cracks, or termite damage helps protect 2x10 members from unexpected failures. Keep humidity under control in enclosed spaces, ensure proper ventilation, and avoid contact with soil or damp substrates unless intentionally designed for such conditions. Guard against accelerated deterioration by using appropriate protective finishes and annual maintenance plans. Finally, always perform load-path checks after renovations or reconfigurations to confirm the modifications did not compromise the structural capacity of the 2x10 members.