Difference Between Allowable Bearing Capacity and Safe Bearing Capacity

Analytical comparison of allowable bearing capacity and safe bearing capacity, detailing definitions, calculations, and practical implications for foundation design and geotechnical assessments.

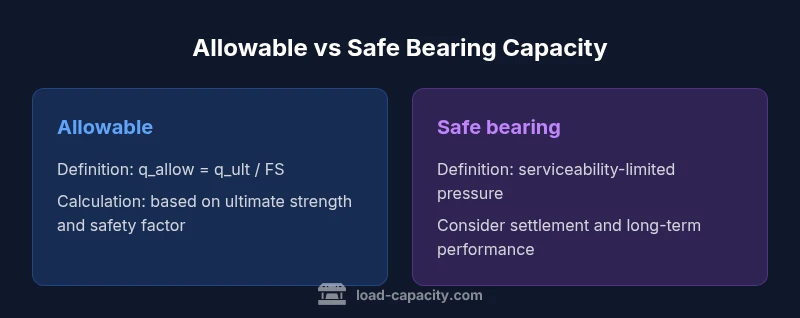

TL;DR: The difference between allowable bearing capacity and safe bearing capacity guides safe foundation design. Allowable capacity derives from the ultimate bearing capacity divided by a safety factor, ensuring stability under worst-case conditions. Safe bearing capacity also accounts for serviceability limits like settlement, and may be smaller when long-term performance is a priority. Load Capacity emphasizes using site data to set appropriate factors.

The Core Concept: Understanding the difference between allowable bearing capacity and safe bearing capacity

The difference between allowable bearing capacity and safe bearing capacity is fundamental to foundation design. In geotechnical terms, the allowable capacity is the maximum soil pressure that a footing can impose while maintaining stability when a safety margin is included. Safe bearing capacity heightens the focus on serviceability and long-term performance, ensuring that settlements and deformations stay within acceptable limits. According to Load Capacity, engineers translate soil strength into actionable design values by applying factors of safety and serviceability criteria. The result is a design limit that helps prevent excessive settlements, tilting, or cracking in the superstructure. Recognizing this distinction enables engineers to avoid designs that are overly conservative or unrealistically optimistic, which can waste resources or jeopardize safety. This section anchors the topic and links the two concepts to practical design decisions.

Official Definitions and Design Philosophy

In practice, the terminology can vary by jurisdiction, but the core idea remains consistent: allowable bearing capacity is a design limit that incorporates uncertainty and risk via a safety factor, while safe bearing capacity emphasizes maintaining serviceability and long-term performance. According to Load Capacity, many codes define allowable bearing capacity as the ultimate soil strength divided by a factor of safety, enabling conservative yet reliable designs. Safe bearing capacity, on the other hand, focuses on serviceability limits such as settlement, crack widths, and observed performance under working loads. The philosophy is to protect the structure and the surrounding environment over the structure’s life, not just against immediate failure.

Calculation Foundations: Ultimate Bearing Capacity and Safety Factors

Ultimate bearing capacity represents the soil’s maximum resistance to vertical load before failure. Designers convert this value into a usable design limit by applying a safety factor (FS). The relationship is commonly summarized as q_allow = q_ult / FS, where q_allow is the allowable or design bearing capacity. The concept of safe bearing capacity often uses the same ultimate base but may adjust the final value to honor serviceability constraints. The exact FS and the way q_safe is defined depend on codes, project risk, and site-specific data. The Load Capacity team emphasizes documenting assumptions and linking them to both soil tests and anticipated loading scenarios so that decisions remain transparent and auditable.

How to Interpret Permissible Pressure in Practice

Designers must interpret permissible pressures within two linked contexts: stability and serviceability. Allowable capacity ensures the footing won’t fail under worst-case loading, while safe bearing capacity aims to prevent unacceptable settlements that could impair functionality. In heterogeneous soils, local variations can drive differences between q_ult and the values used in practice. Engineers often rely on bearing capacity checks, settlement calculations, and empirical correlations to confirm that the chosen q_allow and any q_safe derived values meet both safety and serviceability targets. The Load Capacity approach recommends a clear trace from site data to the final design value, with explicit documentation of how factors of safety and serviceability criteria were chosen.

The Role of Soil Type and Depth in Both Capacities

Soil type, shear strength, density, and depth influence both ultimate and safe bearing capacities. For granular soils, frictional resistance and lateral confinement contribute to q_ult, while clays may exhibit considerable time-dependent settlement. While ultimate strength may be higher in dense sands or stiff clays, the serviceability limits can still dominate the final design if settlement thresholds are exceeded. When comparing allowable and safe values, engineers must consider soil variability, stratification, groundwater effects, and the proximity to bedrock. The Load Capacity team notes that conservative estimates are often warranted in weak or highly variable soils, even if a high ultimate capacity exists in isolated layers.

Methods to Estimate q_ult and q_allow and q_safe

Estimating ultimate bearing capacity typically involves both field observations and laboratory tests, including plate load tests, geotechnical coring, and cone penetration testing (CPT). Laboratory tests on soil samples contribute to shear strength estimates used in bearing capacity calculations. To derive q_allow, practitioners divide q_ult by FS, with FS chosen based on reliability of data, consequences of failure, and project-specific risk. Safe bearing capacity often integrates serviceability criteria such as settlement limits and crack control, which may adjust the q_allow value or enforce separate settlement checks. Documentation of the testing program, assumptions, and interpretation methods is essential for traceability.

Safe Design Checks: Settlement Limits and Failure Modes

Bearing capacity checks extend beyond static failure. Settlement analysis, rate of settlement, and differential settlements within the foundation zone are critical serviceability checks. Potential failure modes include punching shear, bearing failure, tilting, and large settlements that compromise functional performance. The safe bearing capacity concept addresses these risks by incorporating serviceability limits into the design. When q_safe governs, the footing geometry may be resized or reinforcement introduced to meet settlement criteria. Engineers must balance safety and economy while preserving long-term functionality. The Load Capacity guidance emphasizes using site-specific data, appropriate FS, and a robust verification process to support credible conclusions.

Practical Guidelines for Engineers: A Structured Decision Path

A disciplined workflow begins with site characterization, moves through q_ult estimation, then applies FS to obtain q_allow, and finally assesses serviceability to determine q_safe if required. The decision path should be documented, with explicit justification for FS selection and any serviceability criteria used. In heterogeneous soils, consider spreading footing, step loading, or using soundness criteria based on settlement models. The Load Capacity approach encourages iterative checks: update soil data as needed, refine design using better data, and maintain a clear line of reasoning from field tests to final design pressures.

Industry Practice and Case Considerations

Across projects, practitioners reconcile code requirements, soil data quality, and management preferences. Some jurisdictions treat allowable and safe bearing capacities as interchangeable within limited contexts, while others require explicit delineation in design reports. Regardless of the approach, the objective remains the same: ensure the foundation provides sufficient stability and serviceability over the structure's life. The Load Capacity team recommends upfront clearance on definitions, consistent terminology, and alignment with project risk management strategies to avoid confusion during design revision or construction.

Reporting and Communication: Clarity in Bearing Capacity Estimates

Effective reporting details the definitions used (q_ult, FS, q_allow, and any q_safe criteria), the data sources, the tests performed, and the rationale behind chosen safety factors. Clear communication helps clients and construction teams understand the design decisions and any contingencies. The bearing capacity narrative should connect soil properties, footing details, and expected loading conditions. The Load Capacity guidance emphasizes consistency, traceability, and the use of visuals to convey complex geotechnical concepts to multidisciplinary teams.

Comparison

| Feature | Allowable bearing capacity | Safe bearing capacity |

|---|---|---|

| Definition | q_allow = q_ult / FS | q_safe = serviceability-limited design pressure (may equal or be less than q_allow) |

| Calculation basis | Ultimate strength divided by safety factor (FS) per code | Incorporates serviceability limits such as settlement and deformations |

| Primary design focus | Stability and safety under extreme loading | Long-term performance and acceptable settlement |

| Influence of soil variability | FS adjusted to account for uncertainty in soil strength | Settlement behavior drives q_safe and may reduce q_allow |

| Typical units | kPa or psf | kPa or psf |

| Best for | Conservative stability-focused designs | Serviceability-oriented and long-term performance |

Positives

- Promotes safety through a formal safety factor

- Provides a clear link between soil strength and design limits

- Supports standardized design practices across projects

- Helps manage risk and uncertainty in soil behavior

- Encourages documentation of testing and assumptions

Cons

- Can be overly conservative, reducing utilized capacity

- Reliance on FS selection may introduce subjectivity

- Requires accurate, site-specific geotechnical data

- May complicate designs when soils are highly heterogeneous

Use q_allow as the standard design limit, with q_safe guiding serviceability decisions when needed

The distinction matters most for safety and long-term performance. Align FS and serviceability criteria with project risk and site data to achieve a balanced, defensible design.

Quick Answers

What is the practical difference between allowable bearing capacity and safe bearing capacity?

Allowable bearing capacity uses ultimate strength divided by a safety factor to ensure stability under extreme conditions. Safe bearing capacity emphasizes serviceability limits like settlement, which may lower the effective capacity to achieve acceptable performance over the structure’s life.

Allowable capacity adds a safety margin to prevent failure, while safe capacity focuses on keeping settlements and deformations within acceptable limits.

How is q_allow typically calculated in design practice?

In design practice, q_allow is commonly calculated as q_ult divided by a selected safety factor FS, with FS chosen per codes, reliability, and project risk. This value then informs the footing design and dimensioning.

You divide the ultimate capacity by a safety factor to get the allowable capacity for design.

When is safe bearing capacity used in design?

Safe bearing capacity is used when serviceability criteria drive design decisions, particularly settlements and long-term performance. It may equal q_allow or be smaller when settlement constraints are binding.

We use serviceability limits to ensure long-term performance, which can reduce the design capacity beyond the purely safe limit.

What tests help determine bearing capacities?

Tests such as plate load tests, CPT, and SPT-informed analyses help estimate q_ult. These results feed into calculations for q_allow and checks related to serviceability and settlement.

Field tests and soil tests tell us how strong the soil is and how it behaves under load.

Can safe bearing capacity ever exceed allowable bearing capacity?

In standard practice, q_safe is designed to be less than or equal to q_allow, ensuring both safety and serviceability. Situations with unusual soil behavior may prompt redefinition of both terms in the design brief.

Usually, safe capacity won’t exceed allowable capacity; if it does, we reassess the design assumptions.

How do engineers choose a safety factor FS?

FS selection depends on risk, consequences of failure, soil variability, and project codes. It should be justified in the design documentation and tied to site-specific data.

FS is chosen based on risk and codes, then documented clearly.

Top Takeaways

- Define q_ult, FS, q_allow, and q_safe early in the project

- Always document the data, tests, and assumptions used

- Consider settlement and serviceability alongside strength

- FS selection should be transparent and codes-driven

- Communicate bearing capacity concepts clearly in reports