Safe vs Allowable Bearing Pressure: Understanding Bearing Capacity

A precise, analytical comparison of safe bearing capacity and allowable bearing pressure, including calculation approaches, design implications, and common pitfalls for engineers.

Safe bearing capacity is the maximum vertical soil pressure a foundation can carry without shear failure, while allowable bearing pressure is that safe value reduced by a safety margin to control settlement and serviceability. The difference between safe bearing capacity and allowable bearing pressure matters because it guides footing sizing, load distribution, and settlement control. In practice, engineers start with q_safety to ensure ultimate stability, then apply a factor of safety or serviceability criteria to obtain q_allowable, balancing safety and performance.

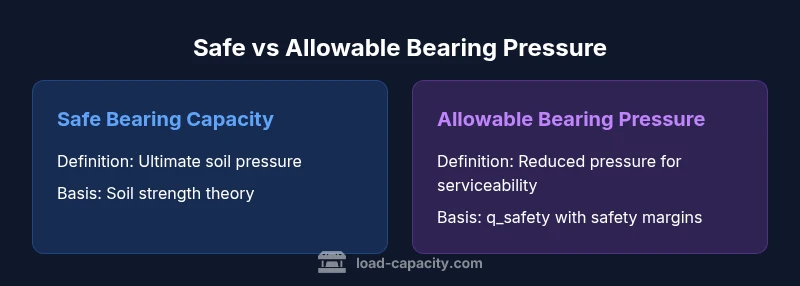

Core definitions: safe bearing capacity vs allowable bearing pressure

Safe bearing capacity is the maximum vertical soil pressure a foundation can carry without shear failure, while allowable bearing pressure is that same capacity reduced by a safety margin to control settlement and serviceability. The difference between safe bearing capacity and allowable bearing pressure matters because it governs how you size footings and distribute loads. In practice engineers start with q_safety to ensure ultimate stability, then apply a factor of safety or serviceability criteria to obtain q_allowable. This distinction underpins reliable designs and helps avoid excessive settlements in real world projects. Load Capacity emphasizes that clarity on these terms supports safer installations across structures and equipment, especially in variable soils and loading conditions.

Key terminologies are used consistently across geotechnical practice, and practitioners should document the chosen approach so that future modifications or load changes remain within acceptable bounds.

Historical context and codes: how standards shape bearing capacity design

Over decades, engineers have refined how safe bearing capacity and allowable bearing pressure are defined and applied. While terminology varies by region, the core principle remains: preserve strength and prevent excessive settlement under anticipated loads. Design codes and geotechnical handbooks encourage explicit definitions, documented soil tests, and explicit serviceability criteria. Load Capacity analysis shows that standardized procedures reduce interpretive risk and foster consistency when comparing soil data, ground conditions, and foundation types. Practitioners should reference local building codes, structural safety guidelines, and geotechnical seminar recommendations to align with best practices while acknowledging soil variability.

This section avoids reliance on single-test results and instead supports integrated judgment that factors in site history, drainage, and potential loading sequences.

Why the distinction matters in design

The distinction between safe bearing capacity and allowable bearing pressure drives the difference between ultimate stability and serviceable performance. If a designer uses only the ultimate capacity, foundations may be over-conservative, increasing cost and construction time. Conversely, relying solely on allowable bearing pressure without adequate safety margins can lead to excessive settlements, misalignment, or long-term performance issues. The Load Capacity team notes that proper separation of these concepts enables engineers to balance safety, cost, and performance, particularly for projects with dynamic loads, poor drainage, or high groundwater influence. A clear decision framework reduces risk and clarifies stakeholder expectations.

In practice, early-stage assessments often produce a q_safety estimate, followed by a site-specific evaluation of settlement limits to define q_allowable.

Determination of Safe Bearing Capacity (q_safety): field tests and theory

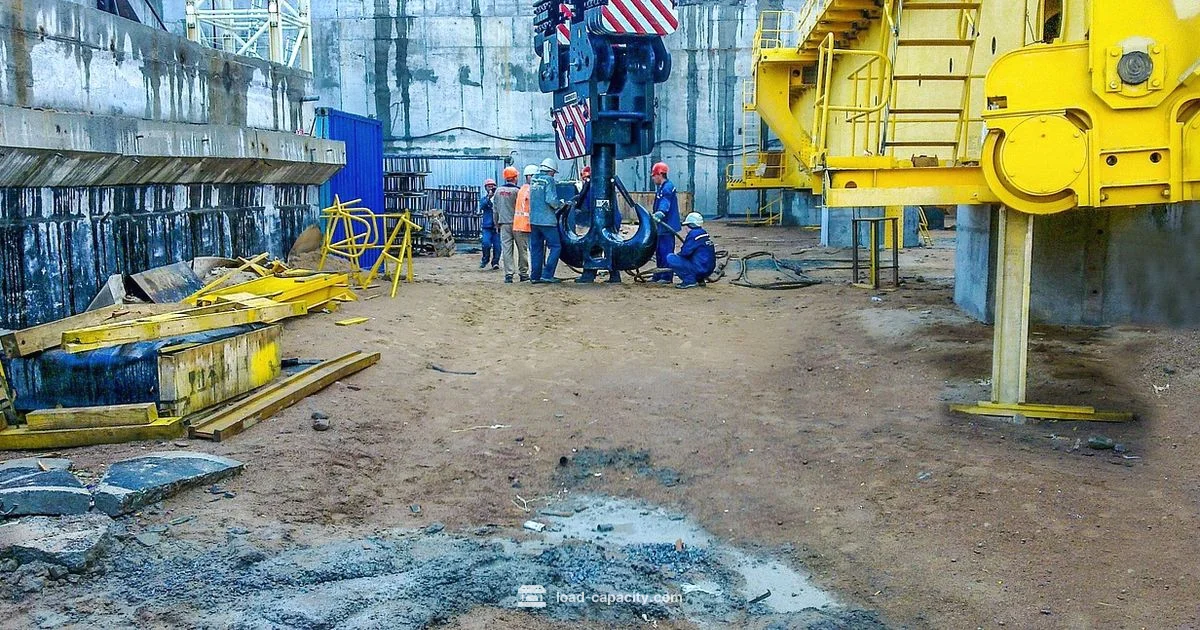

Determining q_safety relies on soil strength theories, bearing capacity calculations, and, when available, direct field tests. Laboratory tests on soil samples provide strength parameters, while field methods such as plate load tests, standard penetration tests, and cone penetration tests help calibrate the ultimate capacity for a given footing size and geometry. It is important to integrate soil stratification, depth to hard strata, and variability across the site. Load Capacity emphasizes that consistent data collection and transparent assumptions are essential so that different engineers can reproduce and validate q_safety estimates. When variability is high, designers should treat the result as a range rather than a single figure and document the uncertainties.

This approach supports defensible designs, especially in weak soils or sites with shoring or excavations.

Determination of Allowable Bearing Pressure (q_allowable): safety, settlement, and serviceability

Deriving q_allowable requires applying a safety margin to q_safety and factoring in settlement criteria, load duration, and serviceability limits. The process typically includes selecting a factor of safety, reviewing eccentric loading effects, and assessing potential differential settlement across the foundation. Drainage conditions, groundwater interaction, and soil type influence the allowable value. The goal is a design that stays within acceptable settlement envelopes over the structure’s life. Load Capacity recommends documenting the rationale for the chosen factor of safety and the settlement thresholds to ensure transparency and consistency across project teams.

In practice, q_allowable is the foundation design baseline that translates soil capacity into practical, installable foundations.

Calculation approaches: comparing q_safety and q_allowable side by side

Conceptually, safe bearing capacity refers to the soil’s ultimate strength, while allowable bearing pressure translates that strength into a serviceable design metric. A common practice is to compute q_safety from soil properties and then derive q_allowable by dividing by a factor of safety and adjusting for settlement controls. The exact FoS varies by project type, risk tolerance, and code guidance, but the underlying logic remains: protect both safety and serviceability. In all cases, explicit documentation of assumptions, soil properties, and load cases is essential to enable peer review and future updates. Engineers should also consider pullout, shear, and lateral stability where relevant.

This section uses general principles to avoid prescriptive numbers while highlighting the relationship between q_safety and q_allowable.

Design implications: when to prioritize safety or serviceability

Different project goals drive whether to emphasize safe bearing capacity or allowable bearing pressure. For critical structures or high-risk soils, designers may lean toward conservative q_safety values to guarantee ultimate stability. For structures with strict serviceability requirements or variable loads, q_allowable with tighter settlement control may be preferable. The Load Capacity team suggests a phased approach: establish safe limits early, then refine allowable values as field tests, monitoring data, and updated soil models become available. Such discipline supports safer, cost-efficient designs that still meet performance criteria.

Practical decision rules include checking the worst-case settlement scenario and ensuring differential settlements stay within acceptable bounds for the intended use.

Common pitfalls and misinterpretations

Misunderstanding the relationship between q_safety and q_allowable can lead to design errors or disputes with owners and contractors. Common mistakes include treating q_allowable as a fixed property of soil rather than a design parameter, neglecting serviceability limits, or failing to update calculations after soil changes or site works. Another pitfall is ignoring the effects of loading duration, drainage changes, or groundwater fluctuations. The Load Capacity guidance emphasizes using explicit assumptions, documenting test methods, and referencing the project’s safety and serviceability targets to avoid ambiguity. Clear communication with the geotechnical team is essential to prevent misapplication of bearing capacity concepts.

The goal is to maintain a rigorous, auditable design process from site reconnaissance to foundation construction.

Worked hypothetical scenario: symbolic calculations without numeric data

Consider a hypothetical soil profile with a defined ultimate capacity and a footing system subject to a range of loads. Using bones of theory, the designer would determine q_safety based on soil strength parameters and then apply a factor of safety to obtain q_allowable. A schematic approach would show how settlement criteria and eccentric loading influence the allowable value. While no numbers are presented here, the workflow demonstrates how designers translate laboratory and field results into actionable design limits. This symbolic example reinforces the clear separation between capacity and serviceability, showing how the two metrics guide planning, sizing, and monitoring plans for foundations.

Engineering teams should ensure that the final designs remain within core safety margins while achieving required serviceability goals.

Regulatory considerations and best practices

Geotechnical design sits at the intersection of safety, code compliance, and practical constraints. Regulators and professional societies emphasize documentation, traceability, and conservative assumptions wherever soil conditions are uncertain. The best practices include performing multiple tests to capture variability, developing a range of safe values, and ensuring that final designs reflect both safety and serviceability requirements. Load Capacity stresses the importance of peer reviews, third-party validation, and transparent reporting to build confidence among stakeholders when applying bearing capacity concepts to real structures and equipment.

Practical tips for engineers and technicians

- Start with a clear definition of the terms used on the project and keep the same definitions across all documentation.

- Use explicit soil test results and keep an auditable trail for the q_safety calculation.

- Define serviceability criteria early and verify that the proposed q_allowable meets those limits through modeling and monitoring.

- Communicate the assumptions and uncertainties openly to avoid disputes during construction.

- Collaborate with the geotechnical team to align on testing, interpretation, and design thresholds.

Load Capacity recommends building a living design file that captures soil properties, test results, safety factors, and monitoring plans to facilitate future updates.

Final checklist: decision factors for safe bearing capacity vs allowable bearing pressure

- Confirm soil type, conditions, and variability across the site, including drainage and groundwater influence.

- Establish the target performance: ultimate stability or serviceability limits.

- Select a credible factor of safety and document its basis.

- Verify that the final footing design complies with both safety margins and settlement criteria.

- Plan for monitoring during construction and early life to adjust q_allowable if necessary.

This checklist helps engineers apply the difference between safe bearing capacity and allowable bearing pressure to practical foundation design.

Comparison

| Feature | Safe Bearing Capacity (q_safety) | Allowable Bearing Pressure (q_allowable) |

|---|---|---|

| Definition | Ultimate soil pressure before failure | Safe pressure enabling serviceability and settlement limits |

| Calculation Basis | Soil strength and foundation theory | q_safety divided by a factor of safety and adjusted for settlements |

| Design Focus | Prevent shear/failure | Prevent excessive settlement and maintain serviceability |

| Design Use | Initial foundation sizing and safety checks | Final sizing considering serviceability |

| Influence of Soil Type | Soil shear strength matters most | Settlement and drainage effects matter more |

| Conservatism | Depends on chosen q_safety, often conservative when FoS is high | Typically more conservative than q_safety due to serviceability concerns |

Positives

- Provides a clear safety margin in design

- Supports compliant, auditable designs

- Helps manage variable soils and loads

- Facilitates communication with stakeholders

- Can be adapted to different project types

Cons

- May lead to over-conservative designs if FoS too high

- Requires reliable soil data and tests

- Can complicate early-phase design due to uncertainties

- Different codes may require different FoS and approaches

Neither concept is inherently superior; use the safe bearing capacity as the safety baseline and derive allowable bearing pressure to meet serviceability goals.

Prioritize safety in early design with q_safety, then refine q_allowable to satisfy settlement limits and project serviceability requirements. In stable soils, a balanced approach minimizes risk and cost.

Quick Answers

What is the practical difference between safe bearing capacity and allowable bearing pressure?

Safe bearing capacity refers to the soil's ultimate strength before failure, while allowable bearing pressure is that strength reduced by a safety factor to meet serviceability requirements. The distinction guides both stability and settlement control in foundation design.

Safe bearing capacity is the soil's ultimate load before failure, and allowable bearing pressure is that value reduced by safety margins to control settlement. This distinction guides safe and serviceable foundation design.

How is safe bearing capacity determined in the field?

Determination relies on soil strength parameters from tests and field methods such as plate load tests or cone penetration tests combined with soil stratification analysis. A robust assessment uses multiple data sources to define a credible q_safety range.

Safe bearing capacity is determined from soil strength tests and field tests like plate loads or CPT, using multiple data sources to define a credible range.

Why apply a factor of safety when deriving q_allowable?

A factor of safety accounts for soil variability, unloading/reloading history, load duration, and construction tolerances. It ensures serviceability and safety under uncertain conditions.

The factor of safety protects against variability and uncertainties, ensuring safety and serviceability under real-world conditions.

Can allowable bearing pressure ever exceed safe bearing capacity?

No. Allowable bearing pressure is derived from the safe bearing capacity by applying a safety margin; it is always less than or equal to the safe capacity.

No, allowable pressure is always derived from the safe capacity and is lower to ensure safety and serviceability.

How do soil type and drainage influence these values?

Soil type governs strength and shear parameters, while drainage and groundwater affect pore pressures and settlement behavior. Both factors influence how q_safety and q_allowable are estimated and validated.

Soil type sets strength; drainage affects pore pressures and settlement, shaping both safety and serviceability estimates.

What happens if settlements exceed limits?

Excessive settlements can misalign structures, cause nonuniform performance, and trigger further design changes. If limits are exceeded, redesign or remediation may be required.

If settlements exceed limits, expect potential misalignment and possible redesign to restore serviceability and safety.

Top Takeaways

- Define terms clearly at project start

- Calculate q_safety first, then derive q_allowable

- Document assumptions and uncertainties

- Account for soil variability and drainage

- Coordinate with geotechnical team throughout