Operating Load vs Lift Capacity: A Comprehensive Comparison

A detailed, engineer-focused comparison of operating load and lift capacity, explaining definitions, methods, safety margins, and design implications for vehicles, structures, and equipment.

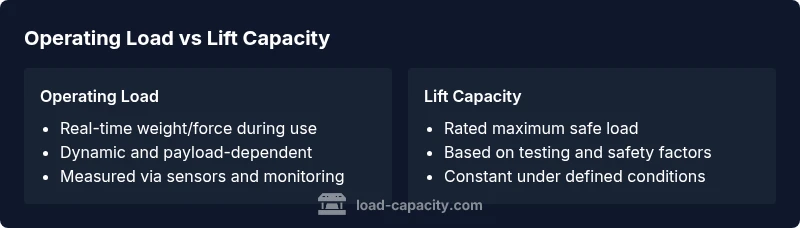

Operating load vs lift capacity distinguishes real in-use forces from rated lifting limits. Operating load is the actual weight or dynamic force encountered during operation, including motion and payload changes. Lift capacity is the maximum safe load a crane, vehicle, or structure is rated to lift or support under defined test conditions. Understanding this distinction helps engineers apply safety margins and prevent overload across contexts.

Understanding operating load and lift capacity

In engineering practice, two core concepts shape how safe and effective a system is: operating load and lift capacity. The operating load, sometimes called in-use load, represents the actual weight or force the system experiences during operation. This includes static weight, dynamic effects from acceleration, deceleration, braking, and any payload or attached equipment. The lift capacity, by contrast, is the rated maximum load the component can safely lift or support under defined testing conditions and safety margins. According to Load Capacity, the distinction matters because real-world use rarely matches idealized test conditions, and safety margins must account for unexpected surges, vibrations, or misloads. In the context of vehicles, trailers, cranes, or building structures, engineers must consider both quantities to prevent structural failure, mechanical overload, or unsafe operating events. The design process typically uses lift capacity as a constraint, with operating load used to verify that actual use stays within safe envelopes. In summary, operating load is a variable, in-use quantity, while lift capacity is a fixed or semi-fixed rating that provides a guaranteed limit under standard conditions."

- tabulation allowed

Comparison

| Feature | Operating load | Lift capacity |

|---|---|---|

| Definition | Actual weight/force experienced in operation (may vary with speed, acceleration, payload) | Rated maximum load the equipment can safely lift or support under testing conditions and safety margins |

| Primary purpose | Ensure safe operation during real use | Provide guaranteed safe lifting limits under defined conditions |

| Measurement basis | Live measurements; dynamic effects; usage profiles | Testing standards; engineering assumptions; safety factors |

| Typical units | kg, lb | kg, lb |

| Dynamic behavior | Fluctuates with motion and duty cycle | Generally fixed within rating conditions |

| Safety margins | Context-dependent; depends on envelope and use | Built into the rating as a factor of safety |

| Usage guidance | Use to monitor and control real-world overload risk | Use as a boundary for equipment selection and operation |

Positives

- Clarifies safety boundaries by separating real-world loads from rating limits

- Promotes proactive risk management through dual checks

- Supports regulatory and audit readiness with explicit margins

- Encourages better instrumentation and monitoring of in-use conditions

- Helps teams communicate risk with clear, measurable criteria

Cons

- Can add design and verification complexity

- May require additional sensors and data analysis

- Risk of confusion if terminology isn\u2019t consistently applied

- Overemphasis on one metric may slow decision making

Adopt a dual-load framework: prioritize lift capacity for guaranteed safety while continuously monitoring operating load to stay within approved envelopes.

Lift capacity sets the guaranteed safe limit under tested conditions, while operating load reflects real-use conditions that can deviate due to dynamics. Using both ensures safety, reliability, and compliance across vehicles, structures, and equipment.

Quick Answers

What is the practical difference between operating load and lift capacity?

Operating load is the real-world weight or force experienced during use, including dynamic effects. Lift capacity is the maximum safe load the equipment is rated to lift under defined testing. They are related but not interchangeable, and both influence safety margins and design decisions.

Operating load is what the system experiences in use; lift capacity is the rated maximum it can safely lift. They aren’t the same, and both matter for safety.

Why should I consider both metrics in design and operation?

Using both metrics provides a complete safety picture: lift capacity ensures a guaranteed limit, while operating load captures real-use conditions. Together they support safer operation, better maintenance planning, and compliant commissioning.

Together they give you a complete safety check for design and use.

How do dynamic factors affect operating load?

Dynamic factors such as acceleration, deceleration, vibration, and payload movement make operating load fluctuate. Proper monitoring and controls help ensure these fluctuations stay within safe envelopes even when loads are not constant.

Movements change the load you actually experience, so monitoring is key.

Can operating load exceed lift capacity?

If real-world operating load approaches or exceeds lift capacity, there is a clear overload risk. This triggers corrective actions such as reducing load, adjusting duty cycles, or upgrading components.

Overload means you need to reduce load or adjust the system.

How are lift capacities typically determined?

Lift capacities are established through testing, industry standards, and engineering safety factors. They are designed to account for worst-case conditions and provide a predictable boundary for safe operation.

Ratings come from testing and standards to keep things safe.

Top Takeaways

- Prioritize lift capacity for safety guarantees

- Monitor operating load to catch in-use overloads

- Use envelopes that account for dynamics and aging

- Document margins to ease audits and maintenance

- Maintain clear terminology to avoid misinterpretation