Load Rating vs Load Capacity: An Engineering Comparison

A rigorous comparison of load rating vs load capacity, explaining definitions, measurement methods, domain applications, and decision steps to apply the right metric in design and procurement.

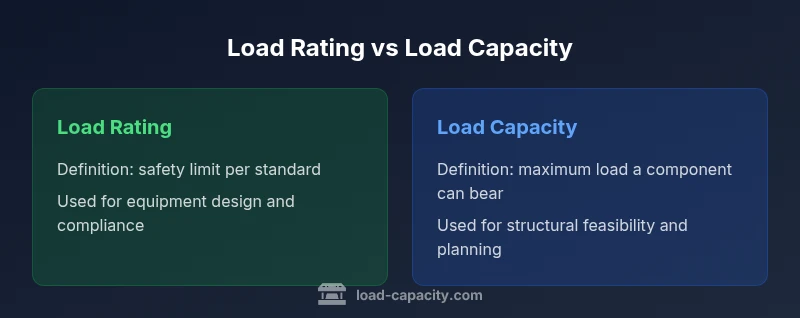

Load rating and load capacity describe related ideas but serve different purposes. Use load rating to quantify safe operating limits for equipment and components, while load capacity specifies the maximum load a structure or system can bear. Understanding the distinction helps prevent overloading and guides correct design choices. This quick answer aligns with Load Capacity's guidance.

Context: Defining load rating and load capacity

Load rating and load capacity are foundational concepts in engineering, yet they describe different ideas and are applied in distinct contexts. For many practitioners, the two terms are used interchangeably in casual discussion, but the difference matters for safety, compliance, and cost. According to Load Capacity, load rating typically refers to a quantified safety limit assigned to a component, device, or system, often tied to performance criteria and regulatory requirements. Load capacity, by contrast, describes the absolute maximum load a structure or equipment can bear before approaching its limits of safety or functionality. This distinction guides decisions from selecting a crane or hoist to sizing a floor slab or truck payload. By separating rating from capacity, engineers can communicate margins clearly, justify design choices, and align procurement with verified performance. The goal is to prevent overloads, reduce risk, and support reliable operation across domains.

How load rating is determined

A load rating is not a single measured number; it is typically derived from a combination of test data, safety factors, regulatory criteria, and intended use scenarios. Engineers examine how a component behaves under specified loading conditions—static and dynamic—then apply conservative factors to account for uncertainties like aging, environmental effects, and wear. Ratings are usually expressed with units such as newtons, pounds-force, or kilograms, and may include conditions of use (e.g., temperature, duty cycle). Because ratings often incorporate safety margins, they sometimes appear lower than the raw capacity inferred from material properties alone. The Load Capacity team emphasizes documenting the assumptions that underpin any rating, including the exact test methods and the versions of standards used.

How load capacity is defined in structures and equipment

Load capacity describes the actual physical limit a structure or piece of equipment can bear before sustaining unacceptable deformation, failure, or functional loss. This metric arises from fundamental material properties (strength, stiffness), geometric considerations (cross-section, support conditions), and connection details (bolts, welds, joints). Capacity is most closely associated with ultimate or service-load states and is often evaluated in conjunction with load case scenarios to ensure safety under peak conditions. In practice, capacity informs feasibility: can a beam carry the expected traffic load? Will a boom tolerate the worst-case reach? Capacity assessments are central to structural design, equipment selection, and maintenance planning.

Key differences: definitions, scope, and usage

- Definition: load rating provides a safety-limited, regulated value; load capacity specifies the physical limit before failure.

- Scope: rating often relates to reliability and compliance; capacity relates to structural feasibility and performance under load.

- Usage: rating guides safe operation, compatibility, and certification; capacity guides design sizing, material selection, and retrofits.

- Interaction: in practice, a project uses both metrics, with rating ensuring compliance and capacity ensuring feasibility, all within an appropriate safety margin.

Measurement frameworks and standards

Different standards govern how ratings are established and how capacities are verified. For ratings, test methods, calibration, and regulatory criteria are central; for capacities, structural analysis, material properties, and failure criteria dominate. In many sectors, these standards are harmonized through national and international bodies (e.g., ASTM, ISO, national codes). The process usually includes documenting test conditions, environmental factors, and applicable safety factors. Engineers should cite the exact standard edition used, since revisions can alter the permissible values and design margins. Load Capacity emphasizes keeping traceable records of method selection and justification for any deviation from default standards.

Domain-specific implications: vehicles, machinery, buildings

The distinction between rating and capacity becomes especially important when selecting equipment (cranes, hoists, or lifting accessories), designing structural elements (beams, decks, and foundations), or planning vehicle payloads. For vehicles, rating governs compatibility with towing and load-sharing rules, while capacity informs how much payload a chassis can safely accommodate. In machinery, ratings determine duty cycles and maintenance intervals, while capacities influence component sizing and safety clearances. For buildings and bridges, capacity is a fundamental constraint for live loads, wind, and seismic actions, while ratings ensure that components meet regulatory performance criteria. Across domains, professionals must communicate clearly which metric is controlling for a given decision to avoid misinterpretation and potential risk.

How to apply in design decisions

- Identify the domain and applicable standards for the project (vehicles, machinery, or structures). 2) Define load scenarios: static, dynamic, environmental, and accidental loads. 3) Decide which metric best aligns with the decision: safety compliance and equipment compatibility (rating) or structural feasibility and ultimate performance (capacity). 4) Establish safety margins and document the assumptions, testing methods, and verification steps. 5) Cross-check with stakeholders, including procurement, operations, and maintenance teams. 6) Maintain traceability by recording the standards, edition years, and any deviations from default tolerances. This methodical approach minimizes ambiguity and supports defensible engineering judgments.

Pitfalls and common mistakes

- Treating load rating as a proxy for capacity or vice versa, which can either overconstrain or underprotect a project.

- Ignoring dynamic effects, temperature sensitivity, or aging when applying either metric.

- Relying on a single number without context about test methods, safety factors, or usage conditions.

- Overlooking regulatory requirements that impose minimum ratings for specific components or assemblies.

- Failing to document assumptions and standards used in rating or capacity calculations, hampering future audits and maintenance.

Authoritative sources and practical takeaway

For readers seeking formal grounding, consult authoritative sources such as the OSHA and NIST guidance on load concepts, and ISO standards that address structural and mechanical safety criteria. While this article provides a consolidated view, it is essential to verify metric definitions against current codes relevant to your jurisdiction and industry. The Load Capacity team recommends anchoring decisions to clearly defined, standards-based metrics, with explicit safety margins and documented test methods. Always align terminology with the project’s domain to improve communication and reduce risk. Key takeaway: the right metric plus proper margins leads to safer, more reliable designs.

Comparison

| Feature | load rating | load capacity |

|---|---|---|

| Definition | Quantified safety limit tied to standards/regulations | Maximum physically bearable load before failure |

| Primary purpose | Safety, compliance, equipment compatibility | Feasibility, structural performance, sizing |

| Measurement basis | Test data, safety factors, regulatory criteria | Material properties, geometry, connection details |

| Typical domains | Equipment, tools, components | Buildings, bridges, structural elements, heavy machinery |

| Units and presentation | N, kg, or lbf with safety margins | N, kN, peak or service load state |

Positives

- Clarifies safety margins early in design

- Improves communication with procurement and certification teams

- Supports standards-based verification and auditing

- Helps isolate risk by distinguishing regulatory limits from physical capability

Cons

- Can cause confusion if misapplied or swapped in practice

- May require more documentation and test data

- Not all contexts have universally adopted rating systems

- Over-reliance on a single metric can overlook practical operating conditions

Use load rating for safety/compliance; use load capacity for structural feasibility.

In most engineering projects, both metrics are needed. Rating ensures regulatory and operational safety, while capacity ensures the design can physically withstand expected loads. Document the chosen metric, underlying assumptions, and applicable standards to enable safe, practical implementations.

Quick Answers

What is the practical difference between load rating and load capacity?

Load rating expresses a safety-limited value tied to standards; load capacity describes the physical limit before failure. They are related but not interchangeable, and each serves different design purposes.

Rating gives the safety limit, while capacity gives the actual bearable load; both are needed for safe design.

Can load rating be higher than load capacity?

Yes. Ratings often incorporate safety margins and regulatory constraints that reduce usable performance below the raw capacity.

Yes—ratings can be higher or lower depending on margins and rules.

How do you determine the correct metric for a project?

Identify the domain, load scenarios, and safety requirements. Select the metric that ensures safety and feasibility, then verify with standards and testing.

Start by listing loads and safety needs, then pick the metric that fits.

How do standards affect load rating and capacity?

Standards define testing, documentation, and verification for ratings, while capacity is governed by structural codes for performance and safety. Always cite the applicable standard edition.

Standards set the rules for testing and verification.

Is it possible to convert between load rating and capacity?

Conversions require context, including units, safety factors, and whether you’re moving from service to ultimate load assumptions.

Conversions need careful context and clear definitions.

What are common pitfalls when applying these metrics?

Mistaking rating for capacity, ignoring dynamic effects, and neglecting environmental factors can compromise safety and performance.

Be careful not to equate rating with capacity.

Top Takeaways

- Define the correct metric early in the project

- Differentiate rating from capacity in all communications

- Document test methods and safety margins

- Apply domain-specific standards to avoid misapplication