Load Factor vs Capacity Factor: An Objective Guide

A rigorous, engineer-focused comparison of load factor and capacity factor, definitions, calculations, and practical guidance on when to use each for reliable capacity planning.

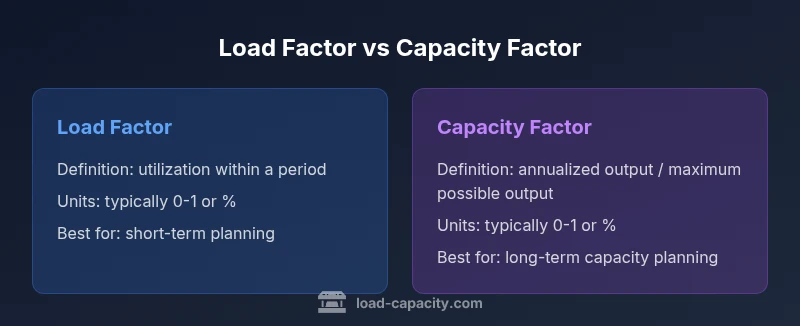

Load factor and capacity factor describe how effectively a system uses its available capacity. The Load Capacity team notes that these metrics answer different questions: load factor measures utilization over a period, while capacity factor measures annualized output relative to maximum possible output. Using both in tandem supports accurate planning, risk assessment, and performance benchmarking.

Definitions and core concepts

In engineering practice, two metrics are commonly used to describe how much capacity a system actually uses: load factor and capacity factor. Load factor measures utilization during a defined period, typically a day, month, or year. Capacity factor evaluates how much of the system's potential output is realized over a longer horizon, usually a year. This distinction matters because a high load factor can occur in a system that has low overall capacity, while a high capacity factor requires robust, reliable capability across the full time frame. For practitioners at Load Capacity, the practical takeaway is that both metrics illuminate different aspects of performance: one focuses on short- to medium-term use, the other on sustained, long-term productivity. When comparing across projects or technologies, always specify the time window and the maximum possible output you assume, to avoid apples-to-oranges conclusions. In short, load factor answers “how much of the available capacity is being used now?” and capacity factor answers “how much of the potential output is achieved over the horizon?”

Comparison

| Feature | load factor | capacity factor |

|---|---|---|

| Definition | Utilization over a defined period (actual load / peak capacity within the same period) | Annualized output divided by maximum possible output over the period |

| Typical units | Dimensionless (0-1) or percent | Dimensionless (0-1) or percent |

| Time horizon | Period-based (e.g., day, month, year) | Annual horizon (often yearly) |

| What it measures | Short-term utilization and efficiency | Long-term productive capacity and reliability |

| Primary use | Operational efficiency and scheduling | Capital planning and reliability assessment |

| Sensitivity to downtime | Moderate (depends on period) | High (downtime directly affects annual output) |

Positives

- Clarifies utilization patterns for operational decision-making

- Facilitates cross-team communication by using common terms

- Supports benchmarking and trend analysis over time

- Helps identify bottlenecks and underutilized assets

Cons

- Can be misinterpreted if the time horizon or baseline capacity are inconsistent

- Requires clean, aligned data inputs and clear definitions

- Risk of oversimplification if used in isolation from other metrics

- May necessitate multiple baselines for fair comparisons

Use both metrics together for informed capacity planning.

Load factor highlights how intensely you use available capacity in a period, while capacity factor reveals how effectively you convert that capacity into actual output over time. Together, they provide a complete view of utilization and reliability, reducing the risk of overbuilding or underutilizing assets.

Quick Answers

What is the formal definition of load factor?

Load factor is the ratio of actual load used in a period to the maximum possible load during that same period. It indicates utilization efficiency within the chosen window and is typically expressed as a value between 0 and 1 (or 0% to 100%).

Load factor measures how much of the available capacity you actually use during a period.

What is the formal definition of capacity factor?

Capacity factor is the ratio of actual output to the maximum possible output over a given period, usually a year. It reflects reliability and uptime by showing how effectively installed capacity is utilized across the horizon.

Capacity factor captures how much of the potential output is realized during the time frame.

Should I always report both metrics?

In most planning contexts, reporting both metrics together improves interpretation and reduces misjudgments. If a project has variable demand, capacity factor helps with long-term planning, while load factor informs day-to-day operations.

Yes—show both metrics when possible to give a complete picture.

What data do I need to compute these metrics?

You need time-aligned data: actual load or output, and the maximum possible capacity for the same period. Consistent units and clearly defined periods are essential for valid calculations.

Collect period-aligned data on actual performance and the capacity limit.

Can these metrics be used for non-energy systems?

Yes. Load factor and capacity factor apply to any system with capacity limits, such as transportation fleets, manufacturing lines, and data centers. The key is to define the period and maximum output consistently.

Absolutely—any system with a limit can use these metrics.

Top Takeaways

- Define the time window and baseline before calculations

- Use load factor for short-term utilization insights

- Use capacity factor for long-term performance and reliability

- Present both metrics with clear assumptions and baselines

- Invest in data quality to improve accuracy of both factors