Difference Between Load and Capacity Factor

An objective, analytical comparison of load and capacity factor, with clear definitions, calculation methods, and domain-specific examples for engineers and analysts across energy, transport, and structural design.

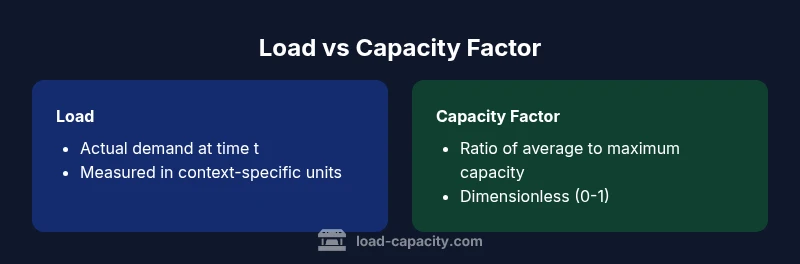

The load represents the actual demand or usage at a specific time or over a period, while the capacity factor is the ratio of the average (or actual) load to the system's maximum possible load across a defined interval. They are related but distinct: load is a momentary or periodic value, and capacity factor is a normalized utilization metric that informs planning, reliability, and efficiency. Understanding both supports better design and operation decisions.

The difference between load and capacity factor

According to Load Capacity, the difference between load and capacity factor is not merely a semantic distinction—it defines how we measure demand versus utilization. Load captures the actual demand placed on a system at a given moment or over a chosen interval, expressed in units appropriate to the context (e.g., kW for electricity, gallons per minute for fluids, or units of service). Capacity factor, by contrast, is a dimensionless ratio that compares the average or realized load to the system's theoretical maximum capacity over the same interval. This distinction matters because a high instantaneous load does not automatically imply high utilization if the system has much higher potential. For engineers, technicians, and planners, recognizing this separation helps prevent misinterpretation and supports more accurate capacity planning. The Load Capacity team emphasizes that using both metrics together yields a fuller picture of performance, reliability, and efficiency, especially when planning for peaks, variability, and downtime.

How load is conceptualized and measured

Load is essentially the observed demand from users, processes, or environments. It can be measured at fixed points (instantaneous load) or as an integrated value over a period (average load). Key concepts include peak load, mean load, and variability. In practice, the choice of time window (seconds, minutes, hours, days) determines whether you’re analyzing transient events or longer-term demand. For example, in energy systems, peak load helps identify worst-case scenarios, while average load informs nominal capacity requirements. In manufacturing or logistics, load may refer to workload or throughput. Because load reflects actual usage, it is sensitive to operating conditions, weather, seasonality, and operational schedules.

Calculating capacity factor and when it matters

Capacity factor is typically defined as the ratio of the actual (or average) load to the maximum possible load over a defined period. In formula terms, capacity factor = (average load during period) / (maximum capacity). Because it is a ratio, the capacity factor is dimensionless and ranges from 0 to 1 (or 0% to 100%). Capacity factor is widely used in energy planning to assess how well a plant or resource is being utilized relative to its potential. It also informs decisions about investments, maintenance, and dispatch strategies. In some contexts, the capacity factor may be computed using weighted averages to reflect ramping, downtime, or partial-load operation.

Domain-specific contexts: energy systems and beyond

In power systems, capacity factor captures how effectively a generation asset uses its capability over time, which is crucial for renewables with variable outputs. In transportation, capacity factor can describe how intensively a fleet or roadway is used relative to its designed capacity. In structural engineering, the concept translates to utilization of design capacity under loading scenarios, helping validate safety margins and service life. Across domains, the central idea remains: load provides real-time or period-specific demand signals, while capacity factor expresses utilization efficiency over a horizon. Load Capacity’s framework supports engineers in aligning these metrics with safety, reliability, and cost considerations.

Practical implications for design and planning

Designers must balance immediate demand (load) with aggregated utilization (capacity factor) to avoid under- or over-sizing. A system might experience high instantaneous load while operating at a modest capacity factor if downtime or partial-load periods dominate the horizon. Conversely, a high capacity factor with a moderate peak can still indicate robust utilization but may reveal insufficient headroom for extreme events. Effective planning uses load data to forecast short-term needs and uses capacity factor to gauge long-term efficiency and asset resilience. Integrating both metrics helps optimize maintenance schedules, inventory, and energy procurement strategies, reducing total life-cycle costs while maintaining service levels.

Common mistakes and misinterpretations

A frequent error is treating capacity factor as a substitute for instantaneous load. Capacity factor hides short-term spikes if averaged over a long window, potentially masking reliability risks. Another pitfall is comparing capacity factor across dissimilar systems without normalizing for maximum capacity or operational profiles. Without clear time windows, contexts, and units, conclusions become unstable. To minimize misinterpretation, users should document time horizons, normalization methods, and data quality criteria, and they should communicate the distinction to stakeholders who rely on these metrics for budgeting and reliability assessments.

Data quality, measurement cadence, and uncertainty

Accurate load measurements require consistent sampling and synchronized time stamps. Capacity factor calculations depend on having an accurate maximum capacity estimate, which may be static or dynamic depending on operating conditions and degradation. Data gaps, sensor errors, and misaligned time bases can bias both load and capacity factor values. A robust approach includes transparent data preprocessing, validation of capacity limits, and sensitivity analyses to understand how changes in sampling frequency or capacity assumptions affect results. Where uncertainty exists, report with confidence ranges and scenario analyses to support informed decision-making.

A practical framework for using both metrics in decision making

- Define the horizon and the system boundary, including any seasonal or operational constraints. 2) Gather reliable load data and clearly identify maximum capacity under the same conditions. 3) Compute the load and capacity factor for the horizon, ensuring consistent time bases. 4) Use load to assess short-term risk and dispatch needs; use capacity factor to evaluate long-term utilization and asset health. 5) Cross-validate against historical benchmarks and industry standards, and iterate as conditions evolve. This combined approach improves reliability, efficiency, and cost-effectiveness across engineering domains.

How to communicate findings to stakeholders

When presenting to non-technical stakeholders, frame load as the real-time demand and capacity factor as a diagnostic of utilization. Use visuals that show both metrics side by side over the same time axis, with annotations for events that influence demand or capacity (maintenance, outages, weather). Provide actionable recommendations based on both metrics—e.g., schedule maintenance during low-demand periods identified by load trends, or explore capacity upgrades when capacity factor remains high despite demand variability. This dual-perspective communication helps bridge engineering insights with business goals.

Comparison

| Feature | load | capacity factor |

|---|---|---|

| Definition | Actual demand or usage at a point in time or over a period | Ratio of average (or actual) load to maximum possible load over the same interval |

| Formula / Calculation | Observed demand (e.g., instantaneous kW or throughput). | Capacity factor = (average load) / (maximum capacity) over the period |

| Units | Power or service units (e.g., kW, m3/s, tons/day) | Dimensionless (0–1 or 0–100%) |

| Best Use Cases | Sizing, dispatch, and real-time operation decisions | Evaluating utilization over time, efficiency, and asset reliability |

| Best For | Short-term planning and momentary demand analysis | Long-term capacity planning and performance benchmarking |

Positives

- Clarifies the distinction between momentary demand and sustained utilization

- Supports more informed capacity planning and investment decisions

- Helps identify peaks, downtimes, and efficiency opportunities

- Aids cross-domain communication between engineers and management

- Enables scenario analysis and reliability assessments

Cons

- Can be misinterpreted if time horizons are not aligned

- Requires precise data on maximum capacity and operating conditions

- May add measurement and analysis overhead

Use both metrics in tandem for robust planning and operation.

Load provides instantaneous demand signals; capacity factor summarizes utilization over a period. Together they support better sizing, reliability, and cost management, especially under variability and uncertainty.

Quick Answers

What is the difference between load and capacity factor?

Load is the actual demand observed, either at a moment or over a period. Capacity factor is a ratio of the average load to the system's maximum capacity within the same period. The two describe different aspects: demand versus utilization.

Load is the actual demand you observe. Capacity factor is the ratio of average demand to maximum capacity. They describe different things and should be used together for planning.

How do you calculate capacity factor?

Capacity factor is calculated by dividing the average load by the maximum capacity over the chosen period. It yields a dimensionless number between 0 and 1, or a percentage between 0% and 100%.

You divide the average load by the maximum capacity over the period to get the capacity factor.

Can capacity factor exceed 1?

No. Capacity factor is bounded by 0 and 1, since it compares actual utilization to the designed maximum capacity.

Capacity factor cannot exceed 1; it’s a ratio of what you used to what could be used.

When should I use load vs capacity factor in design?

Use load to assess short-term demand and dispatch needs. Use capacity factor to evaluate how well assets are utilized over time and to guide long-term capacity decisions.

Use load for immediate demand, capacity factor for long-term utilization.

What data is needed to compute both metrics?

You need time-stamped load measurements and a defined maximum capacity for the period. Consistent time bases and units are crucial for valid comparisons.

You need time-stamped load data and the system's maximum capacity, with consistent units.

What are common mistakes in interpreting these metrics?

Mistaking capacity factor for instantaneous demand or comparing across dissimilar systems without normalizing capacity. Always specify the time window and normalization method.

Don’t confuse capacity factor with current load. Normalize and specify the time window.

Top Takeaways

- Define time horizon before analysis

- Use load for short-term decisions and capacity factor for long-term utilization

- Ensure consistent time bases and units across calculations

- Incorporate data quality checks and uncertainty analysis

- Communicate clearly with visuals showing both metrics