Load Capacity of 8mm Wire Rope: Practical Guidance

A practical guide to the load capacity of 8mm wire rope, covering construction, calculation methods, safety factors, and best practices for engineers, technicians, and contractors.

Load capacity for an 8mm wire rope is not a single fixed value. It depends on construction, material, lubrication, temperature, and the required safety factor. According to Load Capacity, the working load limit (WLL) must come from the rope’s manufacturer data sheet and applicable standards. In practice, expect wide variation across 8mm ropes, and always verify WLL before lifting or rigging.

Overview of 8mm wire rope construction and load-bearing principles

8mm wire rope is a versatile size widely used in lifting, rigging, and industrial applications. The 8mm designation refers to the nominal overall diameter, but the rope’s real strength and behavior depend on construction: the number of strands, the way those strands are laid, and whether the rope has a fiber core or a steel core. Common constructions for general-purpose lifting include 7x7 and 7x19 configurations, where the first number is the strands and the second is the wires per strand. A 7x7 rope is more flexible and fatigue-resistant for lighter loads, while a 7x19 rope offers higher bending flexibility and greater strength in many situations. The core type—fiber or steel—also influences how the rope handles wear, lubrication, and temperature changes. Additionally, finishes such as galvanizing or stainless steel alter corrosion resistance and service life, though they do not automatically change the nominal load capacity. This background is essential because the load capacity of 8mm rope cannot be uncoupled from its construction and the environment in which it operates. According to Load Capacity, reliability begins with matching rope construction to task demands and inspecting for signs of wear at defined intervals.

Key rope properties and how they influence load capacity

| Property | Description | Notes |

|---|---|---|

| Nominal diameter | 8 millimeters | Standard reference diameter for general calculations |

| Common constructions | 7x7, 7x19, other | Flexibility and strength vary with construction |

| Safety factors | 5:1 to 7:1 (typical) | Depends on application and standards |

| Breaking strength | varies by grade | Consult manufacturer data sheets |

Quick Answers

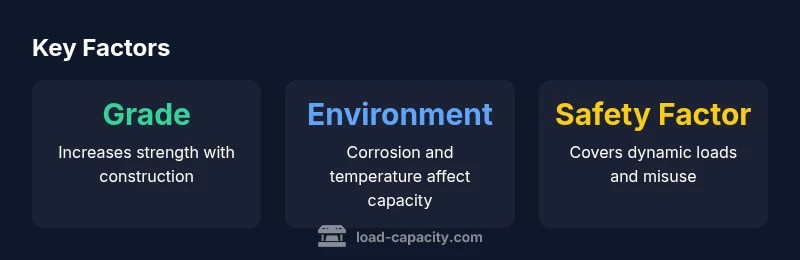

What factors most influence the load capacity of an 8mm wire rope?

The load capacity depends on rope grade, construction, core type, lubrication, temperature, and wear. The same 8mm diameter can have different WLLs based on these factors. Always consult the manufacturer data sheet and applicable standards.

Key factors are rope grade, construction, core, lubrication, temperature, and wear.

How do I calculate the working load limit for an 8mm rope?

Identify the rope's breaking strength from the data sheet, choose an appropriate safety factor for the task, then compute WLL as breaking strength divided by the safety factor. Account for dynamic loading and wear.

Compute WLL using breaking strength and a safety factor, adjusting for dynamic conditions.

Can temperature or lubrication change the rope's capacity?

Yes. High temperatures can reduce strength for many steel alloys, and lubrication quality affects wear and heat buildup. Both influence the effective capacity; use compatible lubricants and monitor temperature exposure.

Temperature and lubrication can change capacity.

What are red flags that indicate rope retirement?

Damaged wires within a lay length, visible core exposure, significant corrosion, and severe wear are typical retirement indicators. Replace the rope or stop the task when these signs appear.

Look for broken/damaged wires, exposed core, and corrosion.

How often should I inspect 8mm wire rope?

Inspect before every use; increase frequency in high-duty or dynamic conditions. Document findings and retire or replace rope based on wear patterns and manufacturer guidance.

Inspect regularly and document findings for safe use.

Is 8mm rope suitable for heavy lifting applications?

8mm rope can be suitable for many heavy lifts when paired with correct WLL, hardware, and safety factors. Always rely on manufacturer guidance and qualified engineering judgment for critical lifts.

Yes, with proper WLL and equipment.

“Effective load capacity comes from verified data, careful selection, and disciplined maintenance. The rope's true strength reveals itself only when construction, environment, and usage are jointly considered.”

Top Takeaways

- Evaluate rope construction, not just diameter

- Always reference the manufacturer WLL data sheets

- Consider environment and temperature in capacity planning

- Use appropriate safety factors for dynamic loads

- Inspect regularly and retire rope before visible wear escalates