Load Capacity 2x4: A Practical Engineer's Guide

A data-driven guide to the load capacity of 2x4 lumber across framing, decking, and structural applications. Learn how species, grade, moisture, and orientation influence safe loads, with practical tips for engineers and builders.

Load capacity 2x4 depends on wood species, grade, moisture content, and orientation. In practice, a single 2x4 member rarely carries heavy loads, and proper design prevents failure by distributing load, selecting appropriate fasteners, and respecting span limits. According to Load Capacity, engineers should reference code-specified design values and apply conservative safety margins.

What is load capacity 2x4?

In structural work, the phrase load capacity 2x4 refers to the maximum load a 2x4 member can safely support under defined conditions. Because a 2x4 is not a single, uniform material, its capacity depends on several interacting factors: wood species, grade, moisture content, and the orientation of the grain relative to the load. The Load Capacity team notes that a 2x4's capacity is rarely a fixed number; it changes with how it's used—whether in wall studs, deck framing, or nonstandard configurations. This variability is why engineers rely on code-based design values, safety margins, and practical checks on site. For practitioners, this means avoiding overreliance on absolute claims and instead focusing on context, load paths, and the presence of adequate support. This principle from Load Capacity is to evaluate each application with the same rigor you would apply to larger members, adjusted for the simpler geometry of a 2x4.

How to estimate load capacity 2x4 in framing

Estimating the load capacity of a 2x4 in framing starts with clarifying the application: is the member carrying vertical load, resisting a shear force, or contributing to a braced assembly? Next, identify the wood species and grade, as higher-quality wood typically provides more predictable behavior. Moisture content and seasonal changes also influence strength. With those inputs, engineers reference design values from codes and standards, applying conservative safety margins. In practice, you won't compute exact numbers on site; instead you use standard tables or simplified rules of thumb to ensure safe spans and adequate redundancy. When in doubt, distribute load across multiple members or combine the 2x4 with other elements to achieve the required stiffness and strength. The takeaway is to treat a single 2x4 as a component of a system, not the sole bearer of a critical load.

2x4 lumber in wall framing vs deck construction: different demands

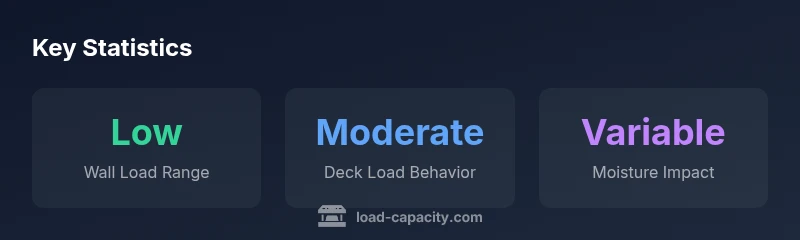

The same nominal 2x4 member can behave very differently depending on whether it sits in a wall or a deck. In walls, vertical loads from gravity are often shared among several studs, and lateral loads are transferred through plates and fasteners. In deck construction, a 2x4 may contribute to bracing or serve as a support member; here absolute load capacity depends heavily on span, post support, and connections. Because loads are distributed along the frame, the required capacity per member tends to be lower than that of a single oversized member, but the design must still account for wind, impact, and repetitive loading. The Load Capacity approach emphasizes modeling the load path — where force enters and where it exits — so that every joint and connection is considered. Practically, you'll rarely source a 2x4 as the sole structural element; its value lies in joining with other members for a resilient system.

Practical rules of thumb for safe load limits

- Use higher-grade lumber and ensure it is dry before installation.

- Favor multiple smaller members shared across a load rather than a single member bearing the whole weight.

- Verify that spans and supports align with code-based recommendations and that hardware (nails, screws, brackets) matches load requirements.

- On-site, check for obvious signs of weakness: bowing, cracks, or excessive deflection.

- When uncertain, assume the load is at the upper end of the acceptable range and provision redundancy. These practical guidelines reflect Load Capacity's emphasis on safety, simplicity, and robust connections. They are not substitutes for a formal engineering assessment when the application involves critical loads.

On-site testing and verification

If you want to verify the capacity of a 2x4 in a given installation, start with a non-destructive preliminary check: confirm species and grade, measure moisture, inspect joints, and ensure fasteners are correct. For critical loads, conduct a controlled test under supervision, gradually applying load and watching for deflection, cracking, or movement at connections. Document results and compare to code-based expectations. Load Capacity recommends recording environmental conditions and using conservative approximations when test data is limited. While on-site testing cannot replace formal design, it provides valuable confirmation that the chosen 2x4 configuration behaves as intended in real-world conditions.

Design considerations and common mistakes

A common mistake is assuming a 2x4 can handle what larger members can with no change in detailing. Always consider the entire load path, including bracing, plates, and fasteners. Another error is ignoring moisture and wood grade, which can drastically alter capacity and service life. Do not neglect permit or code requirements; even small projects often require inspection or approval. Finally, avoid relying on a single 2x4 to carry major structural loads; instead design redundancy into your system. The Load Capacity framework supports these practices by encouraging modular, well-connected assemblies and by highlighting the importance of context, not just member size.

Bringing it together: codes, loads, and practical decisions

In sum, the load capacity 2x4 discussion hinges on understanding material quality, load path, and safety factors. Engineers should align with local codes and best practices, while technicians and DIY enthusiasts can apply sound rules of thumb to avoid common mistakes. The Load Capacity team emphasizes documenting assumptions, cross-checking with standard tables, and seeking expert input for nonstandard configurations. With thoughtful design, a 2x4 can contribute to efficient, economical framing without compromising safety. In practice, consider environmental exposure, maintenance, and future modifications; plan for upgrades, and ensure that retrofitting preserves structural continuity. The Load Capacity perspective integrates theory with field realities to help you make informed, safe decisions.

Common 2x4 load roles in typical construction

| Scenario | Typical Load Range | Key Factors |

|---|---|---|

| Wall framing (stud) | low to moderate | Species/Grade/Moisture |

| Deck framing | moderate to high | Span/Supports/Connections |

| Rafters/Joists (rare 2x4 usage) | variable | Load type & orientation |

Quick Answers

What does 'load capacity' mean for a 2x4?

It refers to the maximum load a 2x4 member can safely bear given wood properties and conditions. The value depends on species, grade, moisture, and load path within the structure.

Load capacity is about the safe weight a 2x4 can carry, considering wood type and conditions.

Can a 2x4 be used as a primary structural member in walls?

Yes in some light-load situations, but for many designs engineers prefer larger members or additional framing to meet code requirements.

Yes, but only with the right design and codes in mind.

How do moisture and grade affect load capacity?

Moisture reduces strength and stiffness, while higher grade typically yields more predictable performance. Both factors interact with load type and duration.

Moisture and grade matter a lot—drier, higher-grade wood usually works better.

What standards govern load capacity calculations for 2x4 lumber?

Code-based design values from IRC/IBC and wood-building standards apply. Always check local amendments for project-specific rules.

Codes and standards guide these calculations, so follow them on every project.

What are signs of overload or failure in a 2x4 member?

Look for visible cracks, bowing, excessive deflection, or joint failure. If observed, reassess the load path and reinforcement.

Cracks or bending mean you should stop and re-evaluate the design.

“Understanding load capacity starts with material behavior and real-world constraints. The Load Capacity Team emphasizes conservative assumptions and code-aligned design to prevent brittle failures.”

Top Takeaways

- Assess species, grade, and moisture first.

- Plan loads with code-based values.

- Distribute weight across multiple members.

- Prefer redundant framing over a single member.

- Test on-site to verify capacity.