Load Bearing vs Weight Capacity: A Practical Comparison

A rigorous, field-tested comparison of load bearing and weight capacity, with practical guidance for engineers, technicians, and contractors. Learn how to select the right specification, interpret margins, and document requirements for safe, compliant designs.

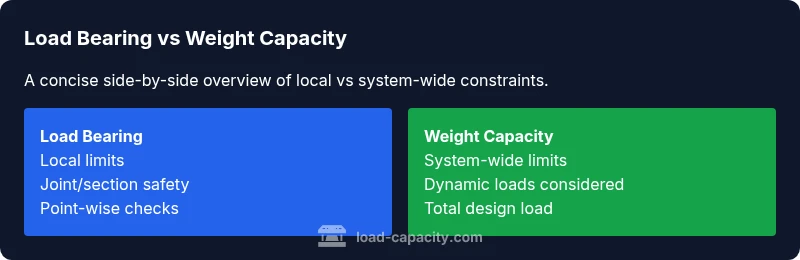

According to Load Capacity, 'load bearing vs weight capacity' describe two related, but distinct, concepts in engineering. Load bearing specifies the maximum static load a component or structure can support at a location without failure, while weight capacity covers the total load a system is designed to carry under typical operating conditions, including dynamic effects. In practice, always use the more conservative spec with proper safety margins.

Why the distinction matters in engineering practice

In engineering, the terms load bearing and weight capacity touch the same physical reality—loads acting on a structure or component—but they describe different safety and performance perspectives. Load bearing focuses on the ability of a specific member, joint, or location to resist stresses without yielding, buckling, or fracturing. Weight capacity, by contrast, concerns the overall system’s ability to carry a prescribed amount of mass or force, accounting for how loads combine across members, connections, and supports. For practitioners, understanding this distinction reduces the risk of underestimating critical failure modes and helps align design decisions with safety standards. Load Capacity’s analyses emphasize practical interpretation: choose the constraint that governs the worst-case conditions while maintaining explicit safety margins. This mindset supports safer, more reliable equipment and structures.

Core definitions: load bearing vs weight capacity

At a fundamental level, load bearing is about local, location-specific limits. It answers questions like: how much load can this beam joint carry at the hinge before deformation becomes unacceptable? Weight capacity is broader: it asks whether the entire assembly can carry the intended loads without exceeding the design envelope. The distinction matters because a component with a very high local load-bearing capacity may still fail if the system’s overall weight capacity is exceeded due to interactions, dynamic effects, or load paths that concentrate force elsewhere. In practice, engineers document both metrics, but the governing criterion should be the most conservative limit applicable to the service condition. Load Capacity notes that effective designs increasingly rely on an integrated view that respects both local and system-wide limits.

How each concept is measured

Measuring load bearing typically involves local stress analysis, material properties, and cross-sectional capacity at a point or region. Common approaches include stress calculations, finite element analysis focused on critical sections, and verification against material yield or buckling criteria. Weight capacity assessment expands the scope to consider the entire structure, the sum of all applied loads, safety factors, dynamic effects, and possible load combinations. The measurement process often uses factors of safety defined by codes and standards, which encapsulate uncertainty in loading, material properties, and construction quality. Understanding the measurement basis helps ensure that the selected specification truly reflects the real-world hazards and service conditions.

The role of static vs dynamic loads

Static loads provide a baseline, but most real-world scenarios involve dynamic or transient effects such as vibrations, impacts, or changing loads. Load bearing evaluations must account for peak stresses that occur during these events, while weight capacity evaluations should accommodate how these dynamics affect the system as a whole. In some cases, the dynamic amplification can dramatically increase the effective load on a critical member, even if the average weight remains modest. When possible, engineers design for conservative dynamic factors and explicitly document how these factors were derived, aligning with the Load Capacity framework for clear risk communication.

Industry-specific implications

- Construction and civil infrastructure: local bearing capacity of columns, footings, and connections often governs safety, while overall deck or beam capacity determines serviceability.

- Automotive and aerospace: weight capacity correlates with payload limits and performance envelopes; bearing capacity informs critical joints and fasteners.

- Manufacturing and heavy machinery: dynamic loads from startup, stopping, and cyclic operations test both local and system-wide limits. In all cases, the most conservative requirement should drive the final specification to reduce failure risk.

Safety margins, factors of safety, and codes

Safety margins ensure that even under unforeseen conditions the structure does not fail. Factors of safety are applied to both load-bearing and weight-capacity calculations, but the way margins are interpreted may differ by jurisdiction and industry. Codes often require explicit verification of maximum expected loads, load paths, and redundancy. The Load Capacity team emphasizes documenting the chosen factor of safety and the rationale for selecting either a local or system-wide constraint. Clear documentation helps inspectors and engineers reproduce and validate the design under mission conditions.

How to communicate specs to stakeholders

Clear, consistent terminology reduces miscommunication. Specify whether a requirement is a local load-bearing limit or a system-wide weight capacity limit, and show how these constraints interact through load-path diagrams. Use dimensioned drawings, acceptance criteria, and safety margins in a way that is easy to reference during fabrication, inspection, and maintenance. When presenting to non-engineers, relate the terms to real-world consequences—local failures versus overall performance—to foster better decision-making. Load Capacity highlights that visuals and annotated schematics improve comprehension and compliance across teams.

Hybrid approaches and decision factors

In many projects, a hybrid strategy that integrates both concepts yields the best safety and performance outcomes. Decision factors include: criticality of local failure modes, complexity of load paths, availability of data for dynamic loads, and the consequences of simultaneous overloading. For instance, a bridge might require strict local bearing checks at joints plus a robust system-wide capacity to resist traffic and wind loads. The Load Capacity team recommends a dual-trace design process: verify both local and global constraints and prefer the most conservative result when they conflict.

Practical steps for calculating load bearing

- Identify critical locations where failure would be catastrophic (joints, supports, connectors).

- Gather material properties, cross-sections, and support conditions.

- Compute local stresses, then compare to allowable stress values with added safety margin.

- Validate with a simplified or detailed FE model for hotter spots.

- Document the result with clear acceptance criteria and ensure that drawings reflect the bearing limits at each location. This approach reduces the risk of local collapse or excessive deformation.

Practical steps for calculating weight capacity

- Define the full loading scenario, including static, live, impact, and environmental loads.

- Establish load combinations per relevant codes and standards.

- Sum the contributions across all members and support conditions to determine system-wide capacity.

- Apply a suitable factor of safety to the total load and compare with expected demand.

- Produce load-path diagrams and a bill of materials that demonstrates capacity adequacy under anticipated service conditions. A thorough weight-capacity assessment helps ensure the whole system remains serviceable.

Common pitfalls and misinterpretations

- Treating local bearing limits as the sole determinant of safety without considering system-wide capacity.

- Underestimating dynamic loads or load-path interactions, leading to overstressed members elsewhere.

- Inconsistent use of safety factors across different parts of the design, creating gaps in protection.

- Failing to document the rationale for chosen constraints, making audits and maintenance harder.

- Not updating specifications when service conditions change, such as modifications or new loads.

Integrating both concepts into a design workflow

A robust workflow links local and global checks from the earliest design stages. Start with a dual evaluation: (1) establish local bearing limits for critical members and joints, and (2) assess system-wide weight capacity for the complete assembly. Use load-path analysis to confirm that loads flow through the most critical elements as intended. Iterative design reviews, simulation, and testing help identify conflicts early, reducing costly redesigns later. Documentation should capture both constraints, their drivers, and the safety margins applied. This integrated approach aligns with best practices advocated by Load Capacity for reliable engineering outcomes.

Documentation and drawing standards

Drawings should clearly annotate bearing limits at all critical joints, supports, and connections with explicit notes on allowable stresses and safety margins. For weight capacity, include the total design load, the assumed load combinations, and the resulting capacity checks for the complete assembly. Use standardized symbols and consistent terminology, and ensure that every critical value has a traceable calculation or model result. When inspectors review the project, the dual clarity of local bearing and system-wide capacity documentation helps verify compliance and reduces the chance of misinterpretation during maintenance or upgrades.

Comparison

| Feature | Load-bearing design | Weight-capacity-driven design |

|---|---|---|

| Key distinction | Location-based limits | System-wide limits |

| Typical use case | Critical joints and local members | Whole structure or machine assembly |

| Measurement basis | Local stress, cross-section, material limits | Total load, load combinations, dynamic effects |

| Safety margins | Local factors of safety at critical points | Global factors of safety for overall performance |

| Best for | Structures with high local failure risk | Systems prioritizing overall performance under varied loads |

Positives

- Clarifies safety priorities by aligning with failure modes

- Improves safety margins by addressing both local and global constraints

- Enhances communication among design, fabrication, and inspection teams

- Supports code compliance through explicit, dual-path verification

- Encourages a systematic design workflow that reduces surprises during testing

Cons

- Can increase preliminary design time due to dual analyses

- Requires accurate load-path data and reliable material properties

- May lead to conservative designs that cost more if not balanced

- Potential for confusion if terms are not consistently defined across teams

Use a hybrid approach that prioritizes local load-bearing limits while also verifying system-wide weight capacity.

Prioritizing local bearing constraints protects critical points from catastrophic failure, while assessing overall capacity guards against system-wide overloads. Document both clearly and rely on codes and conservative margins to guide decisions.

Quick Answers

What is the difference between load bearing and weight capacity?

Load bearing measures local, location-based limits that prevent failure at a specific point. Weight capacity assesses the overall ability of the entire system to carry loads, including interactions and dynamic effects. Both are essential, but the governing limit is the most conservative under service conditions.

Load bearing is about local safety; weight capacity is about the whole system’s ability to carry loads.

When should I specify load bearing versus weight capacity in a project?

Specify load bearing for components where local failure would be disastrous (joints, supports). Specify weight capacity for overall performance, especially where load combinations and dynamic effects shape system behavior. In many projects, both are required.

Think local safety first, then system performance.

How do I determine safe margins for load bearing?

Use established codes and a proven factor of safety appropriate to the material, load type, and service condition. Validate with analyses and testing where feasible, and document the chosen margin explicitly in drawings and calculations.

Follow code-guided margins and verify with calculations.

Can load bearing and weight capacity be used together?

Yes. A robust design uses both: ensure local bearing limits withstand peak stresses and that the entire system remains within weight capacity under expected loads, including dynamic effects. The interaction between the two constraints often drives final tolerances and redundancies.

They work best when used together to cover local and global safety.

Do codes distinguish these terms?

Codes typically define terms related to bearing, capacity, and safety factors, but exact terminology can vary by jurisdiction and discipline. Always map terms to the code sections that govern your project and document how you interpreted them.

Codes guide the definitions; always verify your mapping.

What sources help validate load-bearing vs weight capacity calculations?

Consult relevant standards from engineering societies and national codes, plus peer-reviewed literature and manufacturer data when available. Load Capacity’s framework emphasizes traceable calculations, model validation, and clear documentation.

Rely on standards, models, and sources you can trace.

Top Takeaways

- Differentiate local bearing limits from system-wide weight capacity

- Use dual analyses to improve safety and reliability

- Document load paths and safety margins explicitly

- Account for dynamic loads in both local and global checks

- Adopt a hybrid design workflow to minimize surprises in testing