Difference Between Weight and Capacity: An Analytical Guide

Explore the difference between weight and capacity with clear definitions, practical examples, and actionable guidelines for engineers, technicians, and designers to apply load concepts safely.

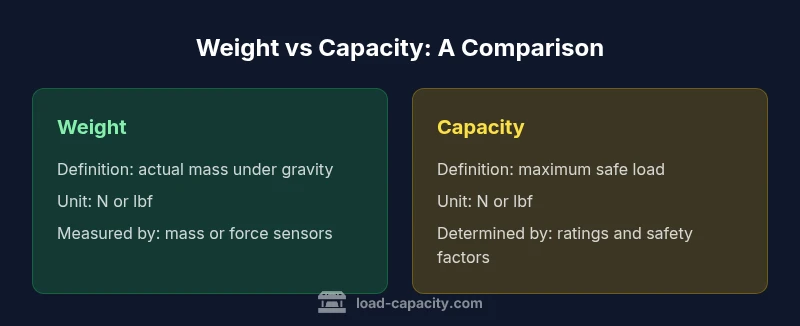

Weight and capacity are two distinct concepts used to describe loads in engineering. Weight measures the actual mass of an object and the force it exerts due to gravity, while capacity defines the maximum permissible load a system can safely handle. Understanding this difference prevents designing around one concept and helps ensure safety, efficiency, and compliance across equipment, vehicles, and structures.

Understanding the Difference Between Weight and Capacity\n\

Units and Measurements: Why Numbers Can Be Confusing\n\

How Weight and Capacity Relate in Real Systems\n\

Common Misconceptions and Pitfalls\n\n- Believing weight equals capacity: they are distinct concepts and must be treated separately in calculations.\n- Assuming capacity remains constant across conditions: capacity can change with configuration, temperature, and wear.\n- Ignoring dynamic effects: moving loads produce higher peak forces than static weight implies.\n- Using a capacity rating as an exact quota: always apply a safety factor and consider duty cycle, reuse, and inspection intervals.\n- Confusing units or misreading datasheets: verify the definitions of SWL, working load limit, and maximum load.

Designing for Safety: Margins, Standards, and Practices\n\

Industry Scenarios: From Vehicles to Structures\n\n- Automotive and trucking: payload capacity determines how much freight a truck can safely carry; weight is the actual mass, while the capacity rating is the limit set by the manufacturer and regulatory bodies.\n- Construction cranes: lifting capacity dictates the maximum mass the crane can move at a given boom angle and radius; dynamic factors like swing and wind can reduce usable capacity.\n- Buildings and bridges: structural capacity governs how much live load a floor, beam, or foundation can carry; engineers sum dead loads, live loads, and environmental forces to verify margins.\n- Industrial equipment: conveyors, lifts, and hoists have rating capacities that guide safe operation; always check the service conditions and maintenance history.\

How to Communicate Weight vs Capacity Clearly\n\

Quick Reference: Key Formulas and Concepts\n\n- Weight W = m × g (mass times gravity). Units: N (SI) or lbf (imperial).\n- Capacity C is a rating defined by the system, often including a safety factor FoS (e.g., C = FoS × W_rating).\n- In practice, design uses W_actual ≤ C; for dynamic loads, apply a multiplier to account for peak forces.\n- Maximum load and SWL: read the datasheet; ensure the context matches your use case (static vs dynamic), and apply a safety margin.\n- Documentation is essential: always cite the standard, test method, and operating conditions that define weight and capacity in your project.

Comparison

| Feature | Weight | Capacity |

|---|---|---|

| Definition | Actual gravitational force on a mass | Upper limit the system can safely support |

| Primary unit | N or lbf | N or lbf |

| Measurement approach | Direct measurement of mass; weight inferred from mass | Engineering rating based on testing and safety factors |

| Primary use | Assess current load and exerted force | Set safe operating limits and design margins |

| Key safety implication | Overloading occurs if weight exceeds capacity | Capacity governs safety margins and compliance |

Positives

- Clarifies design intent and avoids overload

- Improves safety through explicit limits

- Facilitates cross-team communication and documentation

- Supports compliance with standards and codes

Cons

- Can be confusing in early design stages if terms are misapplied

- Capacity numbers may be conservative or vendor-specific

- Requires ongoing verification and maintenance to stay valid

Weight and capacity are distinct but interdependent concepts; treat both correctly for safe, compliant designs.

Use weight to measure actual loads and capacity to define safe limits. Favor explicit safety factors and document assumptions so engineers, technicians, and inspectors stay aligned.

Quick Answers

What is the difference between weight and capacity?

Weight is the actual mass under gravity; capacity is the maximum safe load. They describe different ideas and must be used accordingly.

Weight is mass under gravity; capacity is the safe load limit.

Why can't weight and capacity be used interchangeably?

They measure different things and are used for different decisions in design, testing, and operation.

They measure different things and serve different decisions.

How do you determine safe capacity?

Consult manufacturer ratings, applicable standards, and safety factors; perform calculations and tests under representative conditions.

Check ratings, standards, safety factors, and test under real conditions.

What is SWL vs WLL vs maximum load?

SWL and WLL are terms for safe working limits defined by standards. Maximum load is the upper bound that a system is designed to handle.

SWL and WLL are safe limits; max load is the design upper bound.

How does dynamic loading affect capacity?

Dynamic loads can create peak forces higher than static weight. Always apply factors of safety and consider duty cycles.

Dynamic loads can exceed static weight; use safety factors.

Can capacity change with temperature or wear?

Yes. Capacity can degrade with temperature, wear, and configuration changes; ratings reflect these conditions and should be updated.

Yes, temperature and wear can change capacity.

Top Takeaways

- Define terms clearly in specs.

- Use consistent units for weight and capacity.

- Apply safety factors to published capacity.

- Communicate limits and actual loads to all teams.