Can You Increase Carrying Capacity? A Practical Guide

Learn when and how carrying capacity can be safely increased across vehicles, structures, and equipment. Practical steps, safety standards, and real-world tips to optimize capacity without compromising integrity.

Can you increase carrying capacity? In many contexts, yes, but results depend on the system, loads, and safety margins. This guide explains when you can safely raise carrying capacity for vehicles, structures, or equipment, and outlines practical steps, calculations, and standards to follow. You’ll learn how to assess current limits, identify bottlenecks, and apply proven methods without compromising safety.

Understanding Carrying Capacity and the Question Behind It

Carrying capacity describes the maximum load a system can safely handle without failure or excessive deformation. In practice, the question can you increase carrying capacity hinges on whether the underlying constraints—material strength, geometry, joints, connections, and safety margins—can be adjusted without creating new risks. According to Load Capacity, the most reliable path to higher capacity begins with a clear definition of the operating conditions, followed by a rigorous assessment of how loads travel through the system. This section lays out the fundamental idea: capacity is a property of the entire load path, not a single component. By focusing on the complete load path, engineers can determine whether an increase is feasible, and if so, what combination of design changes, process controls, and testing will preserve safety.

Key Factors That Determine Carrying Capacity

Carrying capacity is not a single number; it emerges from several interacting factors. Material properties set the basic strength and stiffness limits, while geometry defines how load is distributed through the structure. Connections and fasteners determine how forces transfer between parts, and manufacturing tolerances can introduce unforeseen weak points. Environmental conditions, such as temperature, humidity, and vibration, can alter material behavior and long-term performance. Safety margins—design buffers baked into codes and standards—are essential to prevent unexpected overloading. Finally, inspection and maintenance practices influence how well a system sustains its rated capacity over time. Understanding these variables helps decide whether increasing capacity is practical or risky.

Can You Safely Increase Carrying Capacity? When It Makes Sense

Increasing carrying capacity is appropriate when there is evidence that bottlenecks can be addressed without compromising safety. In practice this means: validating that the load path remains intact under higher loads, ensuring joints and connections can carry additional forces, and confirming that materials won’t yield or fatigue prematurely. Incremental changes, supported by testing and monitoring, reduce risk. If critical components show signs of wear, or if the design relies on safety margins that are already tight, increasing capacity may not be advised. The Load Capacity team emphasizes that the safest path is to couple design changes with formal verification and documentation to demonstrate compliance with applicable standards.

Approaches for Vehicles: Boosting Payload Without Compromising Safety

For wheeled platforms, increasing carrying capacity often involves optimizing load distribution, upgrading or re-tuning subsystems, and enhancing monitoring. Practical steps include refining suspension tuning to manage added weight, upgrading tires to handle higher loads with adequate safety margins, and re‑balancing payload to minimize peak loads on axles. Reassessing braking, steering, and drivetrain performance ensures systems respond appropriately under heavier conditions. It’s critical to avoid simply loading up a vehicle without reevaluating the entire load path, as this can mask hidden weaknesses and create failure modes.

Structural and Deck Considerations: Upgrading Capacity in Buildings and Platforms

Structural modifications to increase capacity must respect code requirements and load-path continuity. Common strategies include reinforcing framing members, improving connections, and adding redundancy where failure would be catastrophic. Decks and platforms demand careful attention to local loads, impact forces, and fatigue effects. Before any change, engineers conduct design checks, finite-element analyses where appropriate, and load testing to demonstrate that revised capacity meets safety criteria. Documentation, including revised drawings and calculations, is essential for future inspections and maintenance.

Calculations and Safety Margins: How Engineers Quantify Capacity

Capacity estimation blends static and dynamic considerations. Engineers assess material strength, cross-sectional areas, and stress concentrations, then apply safety factors that reflect uncertainties in real-world use. Dynamic loads—like vibrations, shocks, or rolling loads—can dramatically influence capacity compared with static tests. While formulaic approaches help, the practical takeaway is clear: keep conservative margins and validate with testing under representative conditions. Thorough documentation supports traceability and ongoing compliance with standards.

Real-World Examples and Limits: What Works and What Doesn’t

In practice, several factors limit capacity gains. A stronger component may not compensate for a brittle joint, or a stiffer frame may transfer more stress to smaller elements. Effective capacity enhancements focus on the weakest link in the chain. Case-by-case evaluation, clear scope, and staged implementation help avoid costly mistakes. It’s essential to set realistic expectations and recognize that some systems cannot safely exceed their original design, regardless of improvements elsewhere.

Testing, Validation, and Ongoing Maintenance

Any change aiming to increase capacity should be accompanied by rigorous testing and monitoring. Static tests confirm ultimate strength, while dynamic tests simulate real use to reveal endurance and fatigue behavior. Non-destructive evaluation techniques help detect emerging issues before they become critical. After changes, a maintenance plan with regular inspections ensures the system retains its new capacity and related safety margins over time.

Best Practices, Common Mistakes, and Next Steps

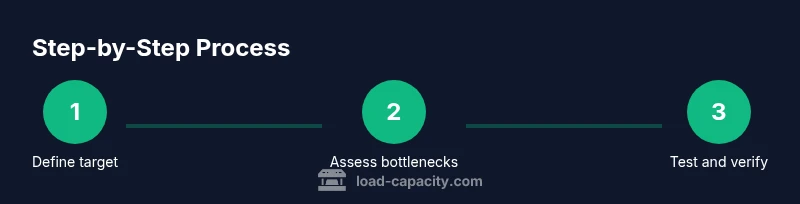

Best practice centers on a disciplined process: define targets, collect data, model scenarios, implement validated changes, and re-test. Avoid common mistakes such as skipping safety reviews, ignoring joint integrity, or rushing through tests. A clear change-control procedure, stakeholder approval, and a robust documentation trail are essential. If the analysis indicates limited or no room to safely increase capacity, pivot to optimizing usage patterns, scheduling, or load management instead.

Closing Thoughts: A Balanced View on Carrying Capacity

Increasing carrying capacity is a nuanced, context-dependent task. When done with rigorous analysis, appropriate testing, and strict adherence to standards, it is possible to achieve meaningful gains without compromising safety. The Load Capacity approach emphasizes thorough assessment, conservative design practice, and transparent documentation to support reliable decisions across engineers, technicians, and operators.

Tools & Materials

- Measurement tools(Calipers, tape measure, and level for precise geometry checks)

- Load-path analysis software(FEM or structural analysis tools if available)

- Safety PPE(Hard hat, eye protection, gloves, and steel-toe boots)

- Non-destructive testing equipment(Dye penetrant, ultrasound, or magnetic particle testers as applicable)

- Documentation tools(Drawings, calculations, and a change-control log)

Steps

Estimated time: 2-4 weeks

- 1

Define target capacity

Specify the exact load level you aim to support and the intended use scenario. Clarify whether the goal is static or dynamic capacity and identify the critical components that influence the limit.

Tip: Write the target in measurable terms and include the environmental conditions. - 2

Gather current data

Collect existing design data, materials, joints, and past testing results. Document current limits, safety margins, and maintenance history to understand what is already in place.

Tip: Check for any undocumented modifications that could affect capacity. - 3

Identify bottlenecks

Analyze the load path to reveal the weakest link. Focus on members, joints, or connections that limit performance when load increases.

Tip: Use a simple schematic to visualize how forces travel through the system. - 4

Model and simulate

Create a mathematical or computational model to evaluate whether proposed changes increase capacity without creating other risks. Compare static and dynamic scenarios.

Tip: Prefer conservative assumptions in early models to avoid over-optimism. - 5

Plan implementation

If the model shows promise, outline hardware changes, process controls, and inspection requirements. Prepare a change-control plan with clear responsibilities.

Tip: Align changes with relevant codes and standards before procurement. - 6

Validate with testing

Conduct representative tests to confirm the new capacity, including safety margins and repeatability. Document results and compare to targets.

Tip: Involve a qualified tester and have an independent review of results. - 7

Document and maintain

Record calculations, test results, and approvals. Establish a maintenance program to monitor performance and protect the new capacity over time.

Tip: Schedule periodic re-testing after major service events or repairs.

Quick Answers

What is carrying capacity in engineering terms?

Carrying capacity is the maximum load a system can safely bear without unacceptable deformation or failure. It depends on material properties, geometry, joints, and safety margins, and it must accommodate dynamic effects when relevant.

Carrying capacity is the maximum safe load a system can bear, considering materials, geometry, joints, and safety margins.

Can any system be upgraded to carry more load?

Not all systems can be upgraded safely. If bottlenecks are widespread or safety margins are tight, increasing capacity may be unsafe. A rigorous assessment, testing, and documentation are essential to decide.

Upgrading isn't always safe; some systems can't safely carry more load without major redesigns and validation.

What standards govern carrying capacity changes?

Standards vary by domain but commonly include structural safety codes, equipment standards, and industry guidelines. Always verify applicability to your jurisdiction and obtain formal approvals.

Standards and codes govern capacity changes; always verify applicable rules and obtain approvals.

How do I start a capacity-increase project?

Start with a clear target, collect existing data, identify bottlenecks, model effects, plan changes, and validate with tests. Keep thorough records to support safety and compliance.

Begin with a clear target, gather data, model changes, and validate with tests, keeping good records.

What risks come with increasing carrying capacity?

Risks include joint failure, fatigue, unexpected resonances, and hidden weaknesses in the load path. Mitigate by testing, conservative design, and ongoing maintenance.

Risks include joint failure and fatigue; address with testing, conservative design, and maintenance.

Is dynamic loading treated the same as static loading?

Dynamic loads can be more demanding due to vibrations and shocks. They require separate analysis and often larger safety margins than static loads.

Dynamic loads need separate analysis and often larger margins due to vibrations and shocks.

Watch Video

Top Takeaways

- Define clear capacity targets before changes.

- Identify bottlenecks along the load path.

- Validate design changes with testing and documentation.

- Maintain conservative safety margins throughout.

- Proceed only with formal approvals and change control.