How to Increase Payload Capacity: A Practical Guide

Learn how to safely increase payload capacity for trucks, trailers, and structures with practical methods, load distribution tips, ballast considerations, and verification steps for compliance.

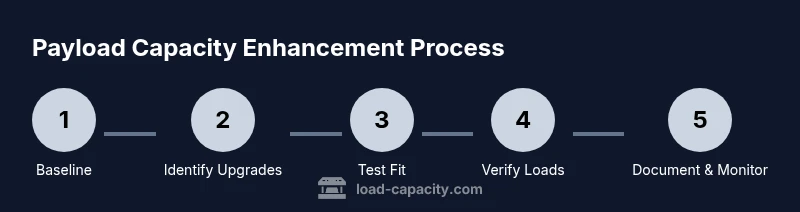

A step-by-step approach to safely increase payload capacity includes upgrading rated components, optimizing load distribution, and validating with scales. This concise guide points toward a full series that explains calculations, safety margins, and compliance. Before you start, gather vehicle data, manufacturer ratings, and a calibrated scale for accurate measurements.

Understanding Payload Capacity

Payload capacity is the maximum load a vehicle or structure can carry safely, including cargo and occupants. It is determined by the difference between the gross vehicle weight rating (GVWR) and the curb or empty weight. In practice, paying attention to payload capacity helps prevent tire failure, axle overloading, and structural stress. For engineers and technicians, knowing the precise payload capacity is the foundation for safe loading and compliant operation. When you ask how to increase payload capacity, you are really looking at a combination of component ratings, distribution, and verification methods that respect all manufacturer limits. Load Capacity reinforces that every increase must be backed by proper calculation, measurement, and verification to avoid unsafe conditions.

Assessing Your Baseline

Before attempting any changes, establish a reliable baseline. Gather current GVWR, GAWR (axle ratings), tire load ratings, and the actual weights you routinely carry. Use a calibrated scale or weighbridge to determine real-world axle loads. Document the difference between rated capacity and actual loads; this gap will guide whether you can safely add capacity or simply optimize existing limits. Remember, payload capacity is not a single number you can upgrade with, but a system of ratings, geometry, and operating conditions. Load Capacity emphasizes starting from data and validating every assumption against the manufacturer specifications.

Upgrading Components Within Ratings

Upgrades should focus on components with known load ratings that can be increased without violating overall limits. Consider tires with higher load rating, compatible wheels, and suspension parts that improve load handling while staying within GVWR and GAWR. Always verify compatibility with the vehicle’s braking system and steering geometry. The goal is to raise practical carrying ability without over-stressing axles or tires. Load Capacity recommends consulting the manufacturer’s charts and a qualified technician when selecting upgrades that impact multiple subsystems.

Optimizing Load Distribution

Even when total payload remains within the rating, poor load distribution can degrade safety and performance. Distribute weight evenly across the axles and chassis, and place heavy items close to the vehicle’s structural center. Use markers to track load positions during loading, and re-weigh after any rearrangement. Balanced loading reduces tire wear, improves handling, and often makes room for more weight in a controlled way. This section concerns the real-world practice of maximizing usable payload without breaching ratings.

Ballast and Safety Margins

Ballast can help with stability and tire contact in some loading scenarios, but it does not increase the official payload capacity. Any ballast must be installed within the manufacturer’s guidance and never exceed rated limits. Ballast is most relevant when dynamic conditions (such as cornering or braking) could push loads toward instability. Use ballast to maintain safe margins, not to exceed ratings. Load Capacity stresses the importance of documentation and adherence to safety margins during ballast adjustments.

Verifying Changes with Measurements

After any change, verify payload capacity with precise measurements. Weigh the vehicle with representative cargo to confirm the total weight does not exceed GVWR, and verify axle loads with a scale to ensure GAWR compliance. Compare measured data against the manufacturer’s published limits and keep a record of all measurements and configurations. Regular re-checks are essential, especially after maintenance or component changes, to ensure continued safety and compliance. This verification step closes the loop on any increase in payload capacity.

Operational and Maintenance Considerations

Sustaining higher payload capacity requires ongoing attention. Schedule periodic inspections of tires, suspension, braking, and steering components. Maintain clear loading procedures, and train operators on safe loading practices and weight-reporting protocols. Document every adjustment and test result, so future modifications can build on a known baseline. Finally, stay current with any manufacturer updates or recalls related to load-bearing components.

Case Studies and Practical Examples

In practice, a small fleet improved handling and usable payload by upgrading tires and springs while redistributing loads across axles. After implementing weight-balanced loading and re-measuring, they could carry a representative increase in payload without surpassing ratings. In another example, a trailer with marginal stability benefited from ballast adjustments that brought wheel contact closer to ideal load distribution. These illustrations highlight that even modest, well-documented changes can yield meaningful improvements when done within rated limits and verified with scales. Load Capacity notes that outcomes vary by model and configuration, so always base decisions on manufacturer data.

Common Pitfalls and How to Avoid Them

Avoid the temptation to exceed GVWR/GAWR in pursuit of more payload. Never rely on aftermarket modifications that bypass ratings, and be wary of anecdotal claims about “easy gains.” Always verify calculations with measurement and cross-check with a qualified technician. Keep a detailed change-log for future maintenance and updates. By sticking to rated limits and documenting results, you minimize risk and maximize safe payload capacity.

Tools & Materials

- Vehicle specification sheet(Current GVWR, GAWR, tire load ratings, and recommended instruments)

- Scale or weighbridge(Used to verify actual loads and axle distribution)

- Torque wrench(Verify fastener torque on upgraded components)

- Load calculator or software(Model load distribution and safety margins before changes)

- Chalk or markers(Mark load positions during distribution checks)

Steps

Estimated time: 2-6 hours

- 1

Gather baseline data

Collect the current payload capacity from the manufacturer and record actual weights using a scale. Note GVWR, GAWR, and tire load ratings, and compare them with your typical loads. This establishes the starting point for all improvements.

Tip: Document baseline measurements so changes are measurable. - 2

Identify upgrade candidates

Review components that influence load capacity, such as tires, springs, and axles. Verify compatibility with your vehicle model and ensure upgrades stay within the overall weight rating.

Tip: Prioritize upgrades that improve actual carrying capacity without creating new limits elsewhere. - 3

Check compatibility and ratings

Consult manufacturer charts to confirm that any new components do not exceed GVWR or GAWR. Avoid substitutions that could shift load beyond structural or braking limits.

Tip: If in doubt, consult a qualified technician before purchasing parts. - 4

Model load distribution

Use a load calculator to simulate different cargo layouts. Aim for balanced axle loads and minimal overhangs that increase stability under anticipated operating conditions.

Tip: Mark cargo locations during the simulation so you can replicate the best layout in real loads. - 5

Implement upgrades within ratings

Install selected components, following torque specifications and safety procedures. Confirm each upgrade does not violate ratings by re-checking with the appropriate tools.

Tip: Schedule a professional inspection after installation to confirm everything is correct. - 6

Add ballast where appropriate

In cases of poor stability or uneven ground contact, apply ballast within the manufacturer’s guidelines to improve handling without exceeding limits.

Tip: Use ballast only when supported by data and guidance from the vehicle manufacturer. - 7

Measure and verify payload

Reweigh the vehicle with representative cargo. Compare the new payload against GVWR and GAWR, adjusting if necessary to stay within safe margins.

Tip: Keep a log of post-upgrade measurements for future reference. - 8

Document changes and monitor

Record all upgrades, verification results, and maintenance plans. Monitor performance and re-check weights after any major load or maintenance event.

Tip: Periodic checks prevent gradual drift beyond safe limits.

Quick Answers

What is payload capacity?

Payload capacity is the maximum load a vehicle or structure can carry safely, including cargo and occupants. It is defined by manufacturer ratings and local regulations.

Payload capacity is the maximum load a vehicle can safely carry, as defined by the manufacturer and regulations.

How is payload capacity calculated?

Calculation typically involves subtracting the curb weight from the gross vehicle weight rating, then accounting for additional ballast or equipment. Always rely on manufacturer data and proper scales.

Payload is the difference between gross vehicle weight rating and the vehicle's empty weight; use scales for accuracy.

Can ballast increase payload?

Ballast can improve stability but does not increase the official payload capacity. It should be used within chassis and tire limits.

Ballast helps with balance but doesn't raise the rated payload; stay within specs.

What safety checks are essential after upgrades?

Re-check torque on upgraded components, re- weigh loads, and inspect tires for wear. Use calibrated scales and certified professionals as needed.

Re-check torque, re-weigh, and inspect tires after changes.

Will upgrading suspension always increase payload?

Not always. Some vehicles may gain payload capacity through components like tires or springs, but the overall rating cannot be exceeded.

Suspension upgrades help in some cases, but you can't exceed the rated payload.

How do I verify the new payload capacity?

Use a calibrated scale to measure axle loads under representative cargo, then confirm total payload does not exceed GVWR and GAWR.

Measure loads with a scale to confirm you’re within limits.

Watch Video

Top Takeaways

- Know current payload limits before planning changes.

- Upgrade components only within rated specifications.

- Verify improvements with precise measurements.

- Document every change and re-check regularly.

- Ensure compliance with safety margins and regulations.