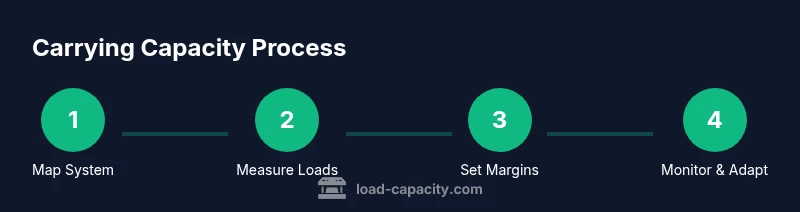

How to Manage Carrying Capacity: A Practical Guide

A comprehensive, step-by-step guide to manage carrying capacity across contexts—ecology, structures, vehicles, and processes. Map boundaries, measure loads, set safety margins, deploy monitoring, and govern changes with practical checklists and real-world examples. Load Capacity provides expert guidance for engineers, technicians, and managers.

Learn how to manage carrying capacity by mapping system boundaries, measuring loads, and setting safety margins. Implement controls, monitoring, and governance to prevent overload and sustain safe, reliable performance across engineering, facilities, and logistics contexts. According to Load Capacity, explicit capacity management reduces risk and improves overall system resilience. This quick guide prepares you for the detailed steps that follow.

Defining carrying capacity across contexts

Carrying capacity is a broad concept that depends on context: ecological carrying capacity describes the maximum population an environment can sustain without irreversibl e damage; structural carrying capacity defines the maximum load a component can safely support; vehicle payload capacity relates to the safe mass that can be transported; process throughput capacity refers to the rate at which a workflow can operate under constraints. Understanding these distinctions helps engineers and managers apply consistent methods across domains. According to Load Capacity, carrying capacity should be defined in terms of safe operating limits, not just maximum observed loads. Start by specifying the boundary and the intended service level—are you ensuring safety, reliability, efficiency, or regulation compliance? Then articulate what constitutes 'load' in your domain: physical weight, pressure, vibration, thermal load, or data throughput. Finally, align stakeholders by documenting the definitions in a shared standard so everyone speaks the same language when measuring and discussing capacity. Consider environment, materials, ageing, and maintenance regimes as part of the boundary, because these factors often shift capacity over time. A clear, well-communicated boundary reduces ambiguity, speeds decision making, and enables consistent testing and qualification across projects.

Why mismanaging carrying capacity costs you

Overloading systems leads to accelerated wear, higher maintenance costs, and safety hazards. In ecosystems, overshoot can cause species decline and habitat damage; in manufacturing or transport, it increases downtime, repair costs, and accident risk. For engineers, mismanaging capacity yields unpredictable performance, unplanned downtime, and regulatory non-compliance. For project managers, it translates into schedule slippage and budget overruns. In many organizations, the absence of explicit capacity governance creates bottlenecks and decision paralysis. The costs are not just financial: reduced stakeholder trust, safety incidents, and liability exposures. The key to mitigation is proactive design: embed capacity checks into design reviews, procurement specs, and operator training. A capacity-aware culture reduces reactive firefighting and fosters evidence-based decisions. Load Capacity's experience shows that teams that document capacity limits and monitor deviations perform better in audits and in real-world operation. The consequence of ignoring capacity is predictable: gradual degradation that culminates in a major failure. Early warning signs include repeated near-misses, rising maintenance frequency, and unusual load patterns.

Step 1: Map your system and boundaries

Begin by listing all components that contribute to carrying capacity, from physical elements to software and human actors. Identify where loads originate, how they travel between subsystems, and where bottlenecks or failure modes live. Draw a boundary diagram that clearly marks inputs, outputs, and interfaces. Define success criteria for your boundary: what reliability, safety, or regulatory requirements must be met? Engage stakeholders from engineering, operations, safety, and finance to ensure the map reflects real operation and governance expectations. The goal is a single, shareable map that makes responsibility clear and reduces miscommunication. A well-defined boundary also helps you isolate the effect of changes when you test capacity adjustments.

Tools & Materials

- Load cell or force-sensing device(Calibrated to a range appropriate for your system. Include a calibration certificate if available.)

- Data logger or high-quality sensor network(Captures time-series data for load and boundary conditions.)

- Measuring tools (tape, calipers)(For physical dimensions and tolerances relevant to capacity.)

- Personal protective equipment (PPE)(Helmets, gloves, eyewear as appropriate for field work.)

- Documentation templates(Standardized forms for capacity definitions, margins, and change requests.)

- Calibration standards(Traceable references to ensure measurement accuracy.)

Steps

Estimated time: 2-3 hours

- 1

Define system boundaries

Create a boundary diagram that captures all relevant components and interfaces. Specify which elements contribute to capacity and which are external constraints. Clarify success criteria and functional objectives to avoid scope creep.

Tip: Review boundary with cross-functional stakeholders to catch overlooked interfaces. - 2

Identify loads and demand sources

List all sources of load within the boundary, including peak conditions and typical operating ranges. Document how loads propagate through the system and where they concentrate at critical points.

Tip: Use worst-case scenarios to stress-test capacity assumptions. - 3

Choose capacity metrics

Select metrics that reflect your domain (e.g., structural stress, vehicle payload, throughput). Ensure units and measurement methods are consistent across all components.

Tip: Prefer metrics that align with regulatory safety factors and design standards. - 4

Set safety margins and limits

Define viable operating limits that exceed expected loads by a safety margin. Document how margins vary with operating conditions and aging.

Tip: Margins should be revisited when loads or materials change. - 5

Design monitoring and controls

Implement sensors, alerts, and governance processes to detect deviations from limits. Ensure rapid communication to responsible teams and clear escalation paths.

Tip: Automate alerts to reduce reaction time during overload events. - 6

Plan governance and review cycles

Establish a formal process for updating capacity definitions, margins, and controls. Schedule regular reviews to incorporate new data and feedback.

Tip: Tie governance to audits and maintenance planning to keep it living.

Quick Answers

What is carrying capacity?

Carrying capacity is the maximum load a system can safely handle without exceeding the defined safety and performance limits. It varies by context and is linked to regulatory standards and operating conditions.

Carrying capacity is the maximum safe load a system can handle, depending on the context and conditions of operation.

How do you determine carrying capacity?

Determine carrying capacity by mapping the system, selecting appropriate metrics, collecting load data, testing under representative conditions, and applying safety margins. Use a governance process to update these limits as conditions change.

You determine carrying capacity by mapping the system, choosing metrics, collecting data, testing, and applying margins with governance.

Why are safety margins important?

Safety margins account for uncertainties such as material aging, environmental variation, and measurement error. They prevent overload and provide a buffer for unexpected conditions, improving reliability and safety.

Safety margins keep systems safe when conditions change or when measurements aren’t perfect.

Can carrying capacity change over time?

Yes. Capacity can change due to aging, wear, environmental factors, maintenance, and operational shifts. Regular re-evaluation ensures limits remain accurate and safe.

Carrying capacity can change as components age or conditions change, so re-evaluation is important.

What tools help manage carrying capacity?

Tools include load sensors, data loggers, boundary diagrams, and governance templates. Use these to collect data, visualize limits, and drive decisions through formal reviews.

Sensors and data tools help you measure capacity and keep decisions grounded in data.

Watch Video

Top Takeaways

- Map system boundaries and critical load points.

- Set measurable capacity limits with safety margins.

- Monitor continuously with alerts and dashboards.

- Document governance for accountability.

- Apply capacity concepts across contexts.