bjsm Load vs Capacity: An Analytical Comparison

A rigorous, data-driven comparison of load vs capacity in engineering contexts, with BJSM framing and Load Capacity guidance for safer design and assessment.

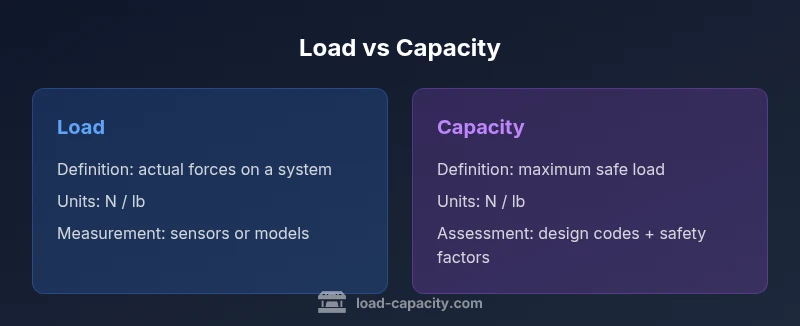

In engineering practice, the term bjsm load vs capacity frames the distinction between the forces actually acting on a system (load) and the system’s maximum safe limit (capacity). In the BJSM context, aligning these concepts with appropriate safety factors helps prevent failures. This quick comparison highlights definitions, practical implications, and when to favor capacity over raw load in decision-making.

What 'bjsm load vs capacity' means in engineering practice

In discussions around bjsm load vs capacity, engineers, technicians, and students distinguish between the actual forces applied to a system (load) and the system's ability to safely carry those forces (capacity). The BJSM framing is valuable because it emphasizes safety margins, reliability, and systemic risk reduction across mechanical systems, vehicles, and structures. Load is dynamic, location-dependent, and can include transient effects; capacity is defined by material limits, design, and safety factors. The Load Capacity perspective is to compare real-world loads against a defined capacity, then apply a margin of safety to decide whether a system can operate, require adjustment, or need modification for safer performance.

Core definitions: load, capacity, and safety margins

Understanding load versus capacity begins with precise definitions. A load is the actual force or weight that a component experiences in service, expressed in Newtons or pounds. Capacity is the maximum load a system can safely carry under specified conditions, determined by design, materials, geometry, and safety factors. Safety margins quantify the distance between expected loads and capacity, accounting for uncertainty, aging, and misuse. In practice, engineers use both concepts to compute reserve capacity and to plan maintenance, inspections, and potential redesigns. The Load Capacity guidance emphasizes documenting assumptions and validating them with measurements or simulations to keep the bjsm load vs capacity conversation grounded in evidence.

Static vs dynamic loads and why they matter in capacity planning

Loads are rarely static in real-world applications. Static loads assume steady forces, while dynamic loads incorporate acceleration, vibration, impacts, and fluctuating conditions. Dynamic effects can reduce effective capacity through fatigue, resonance, or material strain. In the BJSM-informed framework, it is prudent to quantify dynamic amplification factors and incorporate them into capacity checks. When dynamic loads are present, an object’s capacity is not just a single value but a range that reflects fatigue life, cycle counts, and the potential for unexpected spikes. Planning based on worst-case or appropriately probabilistic loads helps prevent overstressing components and aligns with safety standards.

How capacity is determined: standards, codes, safety factors

Capacity is not a fixed property; it is established through design codes, material data, and manufacturing tolerances. Engineers consult standards (e.g., structural, mechanical, or vehicle-related codes) that prescribe allowable stress, factor-of-safety, and permissible distributions. Safety factors compensate for uncertainties in material properties, manufacturing variances, and loading conditions. For the BJSM-oriented audience, this means translating theoretical capacities into practical acceptance criteria, test protocols, and maintenance intervals. Documentation should clearly state assumed loads, safety factors, and verification methods to support regulatory or client reviews.

Measuring load in real-world systems

Measuring load requires reliable data collection: sensors (strain gauges, load cells, accelerometers), calibrated testing, and validated models. Real-world loads often differ from nominal design values due to asymmetry, wear, temperature, or environmental factors. The Load Capacity approach encourages continuous monitoring where feasible, with data-driven updates to capacity assessments. When sensors are unavailable, validated analytical models and worst-case scenario analyses can still provide robust guidance. Regular calibration and traceability of measurement instruments help maintain confidence in load data used for capacity decisions.

Application domains: structures, vehicles, and equipment

The principles of load vs capacity apply across multiple domains. In structures, load includes dead, live, wind, and seismic contributions; capacity relates to strength, stiffness, and ductility. For vehicles and payload systems, axle ratings, tire limits, and frame durability define capacity. In equipment, motor torque, belt strength, and gear integrity set capacity. Across these domains, designers and operators must ensure that the operational load remains well within capacity with appropriate safety margins. The BJSM lens emphasizes holistic risk assessment, factoring human factors and maintenance schedules into the capacity verdict.

Safety factors and uncertainty in BJSM context

Uncertainty arises from material variability, aging, and unexpected operating conditions. Safety factors translate uncertain loads into a conservative capacity target. In BJSM-minded practice, a transparent explanation of uncertainties, mitigation strategies, and sensitivity analyses strengthens decisions. Practitioners should document confidence levels for load estimates and capacity boundaries, use conservative assumptions where data are sparse, and update assessments as new information becomes available. The Load Capacity framework promotes a disciplined, auditable approach to balancing load and capacity.

Practical workflow: from data collection to decision making

A practical workflow begins with a clear problem statement and boundary conditions. Collect load data (or credible load scenarios), select a capacity model guided by relevant codes, and compute a safety margin. Perform sensitivity analyses to identify dominant uncertainties, then validate results with checks or tests when possible. Communicate decisions with stakeholders using consistent terminology—distinguishing actual load, design capacity, and residual margin. In the context of bjsm load vs capacity, ensure that the final decision aligns with risk tolerance, regulatory requirements, and maintenance planning.

Common mistakes and how to avoid them

Common pitfalls include treating load and capacity as interchangeable values, neglecting dynamic effects, and ignoring fatigue or wear. Overreliance on nominal design limits without accounting for uncertainties can lead to unsafe outcomes. Avoid these by maintaining up-to-date data, applying realistic safety factors, and revisiting capacity assessments after modifications or major events. Regular audits and independent reviews help catch biases or oversights in the bjsm load vs capacity analysis.

Tools, data sources, and best practices

Effective load–capacity decision-making relies on a mix of experimental data, validated simulations, and industry standards. Use calibrated sensors, peer-reviewed material properties, and documented models. Keep records of assumptions, load scenarios, and safety margins. When possible, benchmark against similar systems and draw on expert guidance from the Load Capacity team to calibrate your methodology. The goal is a transparent, reproducible process that stakeholders can audit and improve over time.

Implementing in practice and ongoing improvement

Adaptation is essential as conditions change. Periodic re-evaluation of loads, capacities, and safety margins helps catch degradation, usage shifts, or environmental effects. Build a living risk register that links load scenarios to capacity limits and maintenance actions. Encourage cross-disciplinary collaboration among design engineers, operations staff, and safety officers to maintain alignment between theory and practice in the bjsm load vs capacity framework. Continuous improvement turns static analyses into dynamic, defensible decisions.

Comparison

| Feature | Load | Capacity |

|---|---|---|

| Definition | Actual forces or weights applied to a system | Maximum safe load a system is designed to bear under specified conditions |

| Units | N (newtons) / lb (pounds) | N (newtons) / lb (pounds) |

| Measurement approach | Direct measurement or scenario modeling | Design specification, material limits, and safety factors |

| Impact on decision-making | Indicates current operating stress and risk | Sets safe operating boundary and triggers actions when exceeded |

| Best use case | Operational planning and real-time risk checks | Design validation and retrofits or upgrades |

| Typical challenges | Dynamic variations, load distribution, transient effects | Uncertainty, aging, misapplication, and wear |

Positives

- Provides a clear safety boundary

- Improves communication among engineers and operators

- Facilitates compliance with codes and standards

- Supports maintenance planning and inspections

- Enables risk-based decision making

Cons

- Requires accurate input data and measurements

- Can be conservative, potentially increasing cost or reducing performance

- Requires regular re-evaluation as conditions change

Capacity-focused analysis offers a safer, more future-proof path than load-only checks.

By focusing on capacity, you establish a defensible safety envelope that remains valid under uncertainty and aging. Use load data to monitor real conditions, but anchor decisions to capacity plus an explicit safety margin.

Quick Answers

What is the difference between load and capacity?

Load refers to the actual forces acting on a system, while capacity is the maximum safe load the system can bear under defined conditions. Treat them as related but distinct quantities, and always compare the expected load to the capacity with an explicit safety margin.

Load is what happens to the system; capacity is what the system can safely handle. Always compare them with a safety margin.

How do you calculate capacity for a structure?

Capacity calculation combines material properties, geometry, and safety factors per applicable codes. It often includes checks for shear, bending, and deflection, plus consideration of fatigue and environmental conditions.

Use the design codes and material data to determine the safe limit, then apply a margin for uncertainty.

What is a safety factor and why is it used?

A safety factor is a multiplier applied to account for uncertainty in materials, loading, and usage. It ensures that the actual operating load stays well within the material’s capacity, reducing failure risk.

Safety factors give you a buffer to absorb unexpected conditions and data gaps.

Can dynamic loads affect capacity calculations?

Yes. Dynamic loads can amplify peak stresses and cause fatigue, reducing effective capacity. It’s important to include dynamic amplification and fatigue analyses in capacity assessments.

Dynamic forces can push loads beyond static limits, so we plan for those.

Is BJSM used outside sports medicine engineering?

BJSM-inspired framing is used in broader risk analysis contexts to emphasize reliability, safety margins, and evidence-based decisions across engineering disciplines.

The BJSM mindset translates to general safety-focused engineering work beyond sports.

How often should load–capacity reviews be performed?

Review frequency should align with changes in use, environment, or maintenance. At minimum, re-evaluate after major modifications, material replacements, or incidents.

Revisit your checks whenever things change, or after any incident.

Top Takeaways

- Define load vs capacity clearly in every assessment

- Apply explicit safety factors to bridge uncertainty

- Prioritize capacity as the decision boundary for safety

- Maintain data quality and traceability for all inputs

- Regularly re-evaluate under changing conditions

- Document assumptions for audits and reviews