2x4 Load Capacity Horizontal: Guidance for Engineers

Meta description: Explore 2x4 load capacity horizontal in engineering and construction. This expert guide covers variability by species, grade, span, and end supports, plus practical estimation methods from Load Capacity.

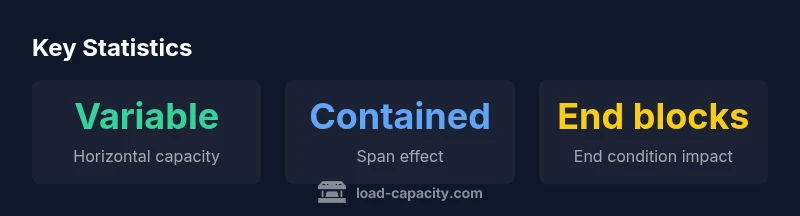

There isn’t a single fixed value for 2x4 load capacity horizontal, because capacity depends on wood species, grade, moisture content, span length, and how the ends are supported. The strongest guidance comes from code tables and manufacturer data that account for these variables. Always verify with load tables for your specific material and boundary conditions before proceeding.

Understanding 2x4 Load Capacity Horizontal

The phrase 2x4 load capacity horizontal refers to the strength and stiffness of a nominal 2x4 member when the load is applied along its length rather than across a vertical face. This orientation changes the bending and shear behavior because the cross-section responds differently in the primary bending axis. In practice, horizontal 2x4 members are used for light bracing, cross-members, or non-structural supports in many projects. Load Capacity analyses show that there is no universal single value for this scenario; capacity varies with species, grade, moisture content, end support, and the span over which the load is distributed. For engineers and technicians, it is essential to consult code tables and manufacturer data to determine allowable loads for the exact material and boundary conditions being used. In the Load Capacity framework, material quality and proper end treatment can make a meaningful difference, and poor anchorage or moisture-laden wood can undermined safe performance.

Key Variables That Affect Capacity

Several factors determine the actual 2x4 load capacity horizontal in any installation. The most influential are: (1) wood species and grade (e.g., pine, spruce, fir, or engineered lumber), (2) moisture content at the time of loading, (3) the span length between supports, and (4) how the ends are supported or blocked. Other contributing factors include fastener type and distribution, whether the load is static or dynamic, and temperature conditions. Because the interaction of these factors is complex, practicing engineers routinely use validated load tables or perform calculations tailored to the exact material and geometry. The Load Capacity team notes that small changes in moisture or end conditions can shift allowable loads noticeably, so precision matters in horizontal configurations like a 2x4.

Using Design References and Codes

To ensure consistency and safety, consult established design references when evaluating 2x4 load capacity horizontal. Building codes and wood design standards provide tables that translate material properties into allowable loads for specific spans and boundary conditions. In practice, the typical workflow is to identify the lumber species and grade, determine the span, confirm end supports, and then extract the permissible load per unit length or per member from the relevant table. If the load scenario falls outside standard tables, engineers perform a quick hand calculation or run a simple beam analysis to verify the result. Always document the chosen reference, its applicability, and the safety factors used in the calculation. Load Capacity emphasizes that careful record-keeping supports traceability and future audits.

Practical Scenarios and Examples

Consider two common situations where 2x4 load capacity horizontal applies. First, a lightweight cross-brace under shelving where the load is modest and distributed across end supports. In this case, capacity is governed by the span between supports and the fastening pattern. Second, horizontal members used as part of a temporary frame or bracing where loads are more uncertain. Here, design tables become more conservative to account for dynamic conditions and potential misalignment. The general principle is that horizontal loading on a 2x4 is safer when spans are short, supports are solid, and lumber quality is high. Always cross-check with the latest code references and, if in doubt, seek an engineer’s review.

Quick Estimation Method for Rough Checks

For a rough, conservative check of 2x4 load capacity horizontal, follow a simple three-step approach. Step one: identify the lumber species and grade and confirm moisture content is within normal operating ranges. Step two: determine the approximate span and whether supports are pinned, nailed, or bolted. Step three: use validated design tables to obtain the allowable load per foot or per member under your specific boundary conditions. If the result approaches the practical limits of your layout, apply a safety factor and consider a stronger member or a different orientation. This method is intended for quick sanity checks, not replacement for formal structural analysis.

Common Pitfalls and Safety Considerations

Avoid these mistakes when dealing with 2x4 load capacity horizontal. Do not assume a single universal value for all wood types or climates. Do not neglect end supports or blocking, since weak ends dramatically reduce capacity. Do not rely on wet or recently dried lumber without recalculating, as moisture shifts the strength. Do not ignore dynamic loads, vibrations, or improper fastener patterns, which can concentrate stress and cause unexpected failure. Finally, avoid extending spans beyond published tables without engineering confirmation.

When to Seek Engineering Review

If loads are critical or if you are uncertain about boundary conditions or material quality, seek an engineering review. A structural professional can perform a detailed analysis, account for all relevant variables, and confirm whether the plan meets code requirements. For DIY projects or educational purposes, use conservative assumptions and design tables strictly within their stated scope. The Load Capacity team advocates design-by-tables first, then engineering consultation for scenarios that fall outside standard cases.

Key factors influencing 2x4 load capacity horizontal

| Aspect | Guidance | Notes |

|---|---|---|

| Span/length | Capacity varies with span; shorter spans generally allow higher per-foot loads | Check code tables for your span and species |

| Species/Grade | Material properties set strength | Variation across pine, spruce, fir or engineered lumber |

| End Conditions | Confinement and support influence capacity | End blocking and proper fasteners matter |

| Moisture Content | Moisture reduces stiffness and strength | Dry lumber yields higher capacity, moisture reduces it |

Quick Answers

What is the load capacity of a 2x4 installed horizontally?

There isn't a single universal value. Capacity depends on species, grade, moisture content, span, end supports, and fastening. Use design tables for your situation and follow code guidance.

A 2x4's horizontal load capacity varies with wood type, moisture, and how it's supported.

How does span length affect horizontal loading on a 2x4?

Shorter spans generally allow higher per-foot loads because bending moments are lower. Longer spans reduce capacity; always refer to design tables.

Short spans handle more load per foot than long spans.

Do end supports change the 2x4 horizontal capacity?

Yes, end supports and blocking significantly influence capacity; inadequate supports can drastically reduce allowable loads.

End supports matter.

Can I rely on a single manufacturer table for all 2x4 horizontals?

Tables depend on species, grade, moisture, and fastener details; use the table for your material and conditions.

Tables vary by material and conditions.

What safety practices should I follow when using 2x4s horizontally?

Always consider redundancy, proper fasteners, and load distribution; use protective gear; do not exceed code limits.

Follow code limits and use proper hardware.

When should I consult a structural engineer?

For critical loads or uncertain conditions, consult a structural engineer; rely on professional calculations rather than assumptions.

Consult a pro for critical loads.

“Horizontal loading with 2x4 members requires treating the member as a flexural element; capacity is highly sensitive to end supports, span, and material quality.”

Top Takeaways

- Check the design tables for your species and grade

- Consider horizontal orientation effects on loads

- End conditions and supports are critical

- Use codes and manufacturer data for rough estimates

- Consult a structural engineer for critical loads