Load Capacity of a 4x4 Post: Practical Guide

A data-driven, practical guide to the load capacity of a 4x4 post, detailing factors, methods, and safe design practices for decks, fences, and light framing.

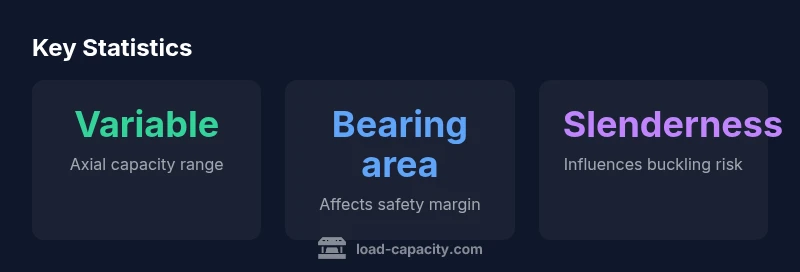

According to Load Capacity Analysis, 2026, the load capacity of a 4x4 post is not a single fixed value. It depends on material species and grade, moisture content, end bearing, post length, and how the post is anchored or connected. In typical light-duty outdoor use, a short, well-supported 4x4 post can resist thousands of pounds axially, but capacity drops with longer spans, inadequate bearing, or slenderness. Always design with local codes and site specifics in mind.

Understanding the load capacity of a 4x4 post

A 4x4 post (nominal 4 inches by 4 inches; actual dimensions are about 3.5" x 3.5") is a staple in light-structure design, from decks to fencing and sign supports. Load capacity is the maximum axial load the member can safely carry under compression before excessive deflection or failure. Wood is anisotropic and moisture-sensitive, so values vary with species, grade, moisture content, and installation details. There is no single universal number; instead, expect a range that reflects end conditions, bearing surfaces, and how the post is restrained at the top and bottom. In practice, design approaches emphasize conservative estimates and verification against local building codes and standards. Load Capacity Analysis, 2026 stresses that you must consider not only capacity but the path that load takes through posts, beams, and connections. This nuanced view helps engineers avoid over-simplified “one-number” specifications and supports safer, real-world designs.

Key factors that influence capacity

Several variables determine the load capacity of a 4x4 post in any given application. The material itself (softwood vs hardwood, and whether it is treated or composite) sets the baseline strength. Grade and moisture content modify that baseline markedly—green or wet wood carries less short-term capacity and can change as it dries. End bearing, or the footprint of the post on a footing or concrete pad, increases capacity if the bearing area is larger. Post length and overall slenderness affect buckling resistance; longer, slender posts are more susceptible to lateral deflection and failure under the same axial load. Fasteners, base plates, and connections transmit load from the post into the footing or adjacent members, making the quality of hardware another critical factor. Finally, environmental exposure, overburden loads (like snow or wind), and corrosion potential for metal fittings all reduce effective capacity in service. Planning must blend all these factors into a coherent design strategy.

Material choices: softwood vs hardwood vs engineered wood

Material selection directly shapes the axial capacity of a 4x4 post. Softwoods (like pine or spruce) are common, cost-effective choices with adequate strength when properly dried and protected. Hardwoods (such as oak or maple) offer higher inherent strength but can be heavier and more expensive, and they may behave differently under moisture cycling. Engineered wood products (e.g., laminated veneer lumber or oriented strand board cores with protective skins) can provide predictable performance and better dimensional stability in some environments, but require proper detailing to connect with standard hardware. The key takeaway is to match the wood type to the load scenario, climate, and permanency of the installation, while ensuring treatment and protection against decay where needed.

End bearing and connection considerations

End bearing is a crucial determinant of capacity. If a post sits on a concrete pad, footing, or a treated base with adequate bearing area, capacity is enhanced compared to a small pad or minimal contact. The interface between the post and its support must transfer load efficiently, so high-quality concrete, rock, or steel bases, plus properly rated fasteners, are essential. Avoid perched loads where the base edge concentrates force on a small contact area. Use full-bearing contact with flat, clean surfaces and consider protective pads if the post bears directly on concrete. When connecting posts to beams or rails, choose hardware rated for the expected load and ensure tight, level seating to prevent premature movement or rocking that reduces overall capacity.

Length, slenderness, and buckling

Buckling is a dominant failure mode for slender posts. The critical buckling load decreases as length increases according to Euler’s formula, so longer posts require larger cross-sectional stiffness or shorter unsupported spans. For a 3.5" x 3.5" post, reducing effective unsupported length and increasing lateral support—via bracing, intermediate posts, or enclosure—can dramatically raise safe axial loads. Practical design recognizes that in real-world installations, posts rarely carry pure end compression; wind, dynamic loads, and adjacent members contribute to the total demand, requiring a conservative approach to post sizing and spacing.

Spacing, bearing, and load path in deck installations

Decks illustrate how load paths influence capacity. Posts spaced too far apart force beams to carry more load, increasing bending demands on those components and altering the required post capacity. Adequate bearing at each post, proper ledger connections, and symmetrical load distribution help ensure the axial capacity of each 4x4 post is used efficiently. In many jurisdictions, guardrails, stairs, and cantilever elements also impose additional loads that must be accounted for in the post design. A holistic view—considering posts, beams, joists, and rail connections—achieves safe and durable performance.

Safety margins, codes, and design practices

Engineers apply safety factors and design per local codes (e.g., IBC or jurisdictional supplements) to accommodate variability in material properties and installation. Design practices emphasize conservative estimates, verification through field checks, and a bias toward simplicity and redundancy where feasible. When in doubt, standard practice includes using larger or additional posts, reducing spans, or increasing bearing area to maintain adequate stiffness and serviceability under anticipated loads. Documentation of material specs, installation details, and protective measures supports traceability and future maintenance.

Field testing and practical verification

Field verification can be performed through non-destructive checks, visual inspection of connections, and, where permissible, staged loading experiments with calibrated equipment. For most residential and light-commercial applications, a thorough inspection of bearing surfaces, fastener integrity, and post alignment provides substantial confidence. Where high-stress conditions exist or structural elements are critical for life-safety, professional testing and calculation review are advised. Documented test results help confirm that assumptions about capacity align with real-world behavior.

Quick-start checklist for practitioners

- Identify species, grade, and moisture status of the 4x4 post.

- Confirm end bearing area and footing condition.

- Assess post length and reasonable spacing to control slenderness.

- Inspect connections and fasteners for proper sizing and corrosion resistance.

- Compare loads to local code requirements and include a safety margin.

Key factors influencing the load capacity of a 4x4 post

| Factor | Impact on capacity | Notes |

|---|---|---|

| Material type (softwood vs hardwood) | Influences baseline strength | Depends on species and grade |

| Moisture content | Alters strength and stiffness | Drier wood generally stronger in compression |

| End bearing area | Increases capacity with larger contact area | Ensure flat, clean bearing surfaces |

| Post length / slenderness | Affects buckling risk | Consider bracing or shorter spans |

Quick Answers

What determines the load capacity of a 4x4 post?

Capacity is influenced by wood species and grade, moisture, end bearing, post length, and how the post is anchored. Load paths through connections and supporting members also affect the effective capacity.

Capacity depends on wood type, moisture, bearing, length, and how you anchor it; load paths matter, so plan accordingly.

Does a longer post always mean lower capacity?

Longer posts have higher buckling risk, which can reduce safe axial loads. The effect depends on cross-section, material, bearing, and lateral support.

Yes, longer posts are more prone to buckling unless you add support or choose a stiffer configuration.

Are deck posts more critical than fence posts for capacity?

Deck posts often experience lateral loads from beams and railings, plus wind, which can affect capacity differently than fence posts. Both require proper bearing and connections, but decks usually demand more careful load-path design.

Deck posts face more complex loads, so verify bearing and connections carefully.

Can I rely on a single number for code compliance?

No. Codes require design based on material properties, geometry, and load cases, with safety factors. Use a range of capacities and verify with calculations and field checks.

No—design must account for variability and safety margins.

What testing can verify a post’s capacity in the field?

Non-destructive inspections of bearing surfaces and connections help. In high-stakes applications, calibrated load testing by an engineer provides confirmation under controlled conditions.

Check bearing surfaces, then consider professional testing if the post is critical.

What are practical strategies to improve capacity safely?

Increase bearing area, shorten unsupported spans, use bracing, and select higher-grade or stiffer wood. Pair with appropriate hardware and follow local codes.

Increase bearing, reduce length, brace, and use proper hardware.

“There is no universal single-value load capacity for a 4x4 post; capacity depends on material, geometry, and how it is supported. Design with the load path in mind and verify against applicable codes.”

Top Takeaways

- Assess species, grade, and moisture before design

- Maximize bearing area to improve capacity

- Control slenderness with spacing and bracing

- Use conservative safety margins per local codes

- Verify design with field checks and appropriate hardware