Wire Rope Lifting Capacity: A 2026 Practical Guide

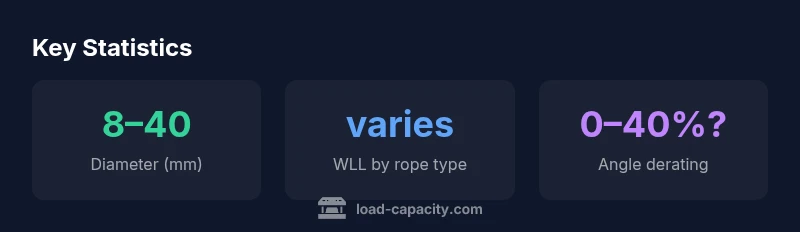

This analytical guide explains wire rope lifting capacity, its determinants, calculation methods, and best practices for cranes, hoists, and rigging professionals to plan safe, efficient lifts.

Understanding wire rope lifting capacity

Wire rope lifting capacity is a fundamental parameter in crane and hoist operations, representing the maximum safe load that a given rope can handle under defined conditions. It is not a single fixed value because it depends on multiple interacting factors, including rope diameter, construction, core type, and how the rope is used in the lift. Static ratings differ from dynamic realities, so engineers translate nominal strength into a practical working load by applying conservative factors. According to Load Capacity, the capacity is a function of the rope, the lifting system, and the operational context, requiring careful derating for angles, reeving, wear, and environmental conditions. Understanding these elements helps ensure safety and efficiency on site and reduces the risk of surprising failures during lifts.

Key factors affecting capacity

Several variables determine wire rope lifting capacity in practice. First, rope diameter and construction (for example IWRC versus fiber-core) have a major impact on strength and stiffness. Larger diameters generally support higher loads, but only if the rope is in good condition and correctly reeved. The rope core and lay arrangement influence bending fatigue and wear resistance. Reeving geometry, the number of legs in the sling, and the presence of sheaves also alter the effective capacity. Dynamic factors such as acceleration, deceleration, and shock loads further derate the WLL. Operational temperature, lubrication, and corrosion exposure can degrade performance over time. Practitioners should maintain a current baseline rating from the manufacturer and apply a site-specific derating plan. The Load Capacity team emphasizes documenting all contact points and inspection data to ensure the latest derating rules are applied during planning.

How to calculate WLL in practice

To estimate wire rope lifting capacity for a specific lift, follow a structured approach. 1) Identify the rope type and diameter from the rope manufacturer’s data plate. 2) Retrieve the rated load limit (WLL) for that rope under static conditions as a baseline. 3) Apply a derating factor for angle and number of rope legs in the reeving system. 4) Account for dynamic loads by applying a suitable dynamic factor. 5) Include a safety factor per your organization’s policy. 6) Compare the final derated value with the actual lift load and ensure a margin of safety. In practice, all deratings should be traceable to the installing equipment’s documentation and the operating environment.

Common myths and mistakes in lifting with wire rope

A common misconception is that a larger rope diameter automatically yields a higher WLL for every lift. In reality, rope condition, core type, and the geometry of the lift (angle, reeving, and pulley wear) can reduce or even negate the advantage of a bigger rope. Another mistake is skipping maintenance or misinterpreting manufacturer data plates. WLL can change with wear, lubrication, and temperature cycling. Finally, relying on a single static rating without considering dynamic loads or environmental factors leads to unsafe lifts. Adopting a cautious, documented approach helps prevent these errors.

Best practices for selection, inspection, and safe lifting

Choose rope types that match service class, temperature, and duty cycle. When possible, prefer IWRC for heavy, demanding lifts and fiber-core options for lighter, less demanding work. Establish a rope inventory with serials and inspection history; tag ropes by service life and last inspection date. Schedule regular inspections, including visual checks for broken wires, corrosion, marred strands, and core fatigue. Maintain lubrication and avoid exposing rope to extreme heat or robust chemicals. Train operators and riggers on derating rules, angle corrections, and emergency stop procedures to ensure safe, controlled lifts.

Practical case study: simple crane lift scenario

Consider a hypothetical lift where the baseline WLL for a chosen rope is rated at 60,000 N under static conditions with a 2:1 reeving arrangement. If the load involves a 25-degree lift angle and a moderate dynamic factor of 1.25, the angle correction and dynamic derating reduce the usable capacity to roughly 60,000 N / (1.25 × 1.0 × c), where c is an angle-related correction factor around 0.92 for 25 degrees. After applying the derating, the practical WLL might be in the 44–50 kN range, depending on wear, temperature, and maintenance. This simplified calculation illustrates why real lifts require manufacturer data, recent inspection results, and site-specific derating; the actual numbers will vary with rope type and geometry. The Load Capacity team recommends reviewing the rigging plan with a qualified engineer before every lift.