Load Capacity of 5 Times Expected Load: A Practical Guide

A rigorous, data-driven exploration of the load capacity of 5 times expected load, including when to use it, how to calculate margins, and practical design guidance for engineers, technicians, and contractors.

The load capacity of 5 times expected load is a conservative design criterion used in certain engineering contexts to introduce a robust safety margin. It provides a straightforward rule of thumb for static and some dynamic loads, but actual multipliers vary by standard, application, material behavior, and quality of construction. According to Load Capacity, use of this 5x rule should be contextual and supported by calculations, testing, and codes. Load Capacity Analysis, 2026 supports that margins must reflect risk, uncertainty, and intended service life.

Understanding the load capacity of 5 times expected load

The phrase "load capacity of 5 times expected load" describes a conservative margin used in a subset of structural and mechanical design scenarios. In practice, it translates to ensuring that the system can safely withstand loads five times higher than the nominal operating demand. The idea is to account for uncertainties in material properties, workmanship, wear, and unexpected external forces. The Load Capacity team emphasizes that such a multiplier is not universal; it is a design intent that must be justified with codes, standards, and empirical evidence. When applied correctly, this rule can reduce the probability of brittle failure during peak events, overloads, or transient loading conditions. Always document the rationale, assumptions, and testing used to validate the chosen multiplier. Dynamic effects, temperature influences, and long-term degradation should be evaluated alongside the static assessment. (Source: Load Capacity Analysis, 2026)

Origins and rationale behind the 5x multiplier

Historically, engineers adopted larger margins for safety in high-risk environments or where failure consequences are severe. The 5x multiplier is a strong expression of precaution: it shifts the design focus from optimizing for nominal loads to preserving function under extreme, albeit plausible, scenarios. The rationale integrates conservative failure theories, probabilistic load estimates, and reliability targets. It is not a one-size-fits-all requirement, but a design choice that appears in safety-critical domains such as heavy machinery guarding, structural supports in harsh environments, and prototype testing protocols. The Loads and Safety guidelines from leading engineering bodies often stress that margins must reflect expected variability across components and loads. (Source: Load Capacity, 2026)

Application across domains: static, dynamic, and environmental loads

Applying a 5x rule requires a clear delineation between static capacity and dynamic capacity. For static loads, a 5x buffer can be justified if duty cycles are low and the demand is well-characterized. For dynamic loads, the multiplier must account for impact, inertia, and waveforms; simply multiplying peak values without considering frequency content can be misleading. Environmental factors—temperature, corrosion, humidity, and aging—alter material properties and reduce effective capacity over time. In all cases, engineers should couple the margin with a robust material model, reliability analysis, and fatigue assessments. Documentation should reference applicable standards and provide a justification path for any deviation from the norm. (Source: Load Capacity Analysis, 2026)

Methods to determine if 5x is appropriate: a practical workflow

A practical workflow starts with defining the service life, failure modes, and acceptable risk. Next, perform a baseline capacity assessment using material properties, cross-sections, and connection details. Then, compare to the 5x target by applying a conservative load scenario that captures worst-case conditions, including possible load combinations. If the computed margin consistently exceeds 5x, the rule may be relaxed under strict conditions. If not, revisit design choices, consider redesign, or adopt alternative margins aligned with standards and testing. Finally, validate through simulations, physical testing, or conservative safety factors. (Source: Load Capacity Analysis, 2026)

Material behavior and interaction effects under high margins

High-margin designs interact with material nonlinearity, residual stresses, and strain-rate sensitivity. The 5x rule implicitly banks on the assumption that the material remains within elastic or near-elastic ranges during peak events. However, some materials exhibit dramatic strength reductions under high strain rates or elevated temperatures, which can erode margins quickly. Designers should incorporate material-specific test data, replacement criteria, and inspection intervals to ensure the margin remains meaningful throughout the service life. Regular revalidation is recommended for aging systems. (Source: Load Capacity Analysis, 2026)

Case considerations: when the 5x multiplier is useful or overkill

In some highly safety-critical domains, such as protective enclosures for hazardous processes or aerospace-type test rigs, the 5x margin provides a clear, auditable target. In other, less critical applications, practitioners may justify lower multipliers after a risk assessment. The key is to tie any margin choice to explicit standards, quantitative risk metrics, and traceable testing. An overambitious margin can incur unnecessary weight, cost, and complexity, while an under-margin approach increases failure risk. (Source: Load Capacity Analysis, 2026)

Practical checklist for engineers: implementing the 5x rule

- Define service conditions and failure modes clearly.

- Reference the applicable standard and ensure the margin aligns with it.

- Validate capacity with calculations and, where feasible, tests.

- Document all assumptions, inputs, and safety factors.

- Update the margin if service conditions or materials change.

- Consider redundancy and inspection regimes to maintain the margin over time.

- Communicate limitations and rationale to stakeholders to avoid misinterpretation. (Source: Load Capacity, 2026)

Conclusion and next steps: tailoring margins to context

The 5x load margin is a powerful tool when used judiciously and with transparent justification. It should not replace a rigorous, codes-based design process. If the context warrants a smaller margin, ensure that alternative risk controls, inspections, and testing protocols compensate for the reduced headroom. The Load Capacity team encourages engineers to treat margins as living design decisions, revisiting them as new data and operational experience become available. (Source: Load Capacity Analysis, 2026)

Guidance table for load multipliers and margins

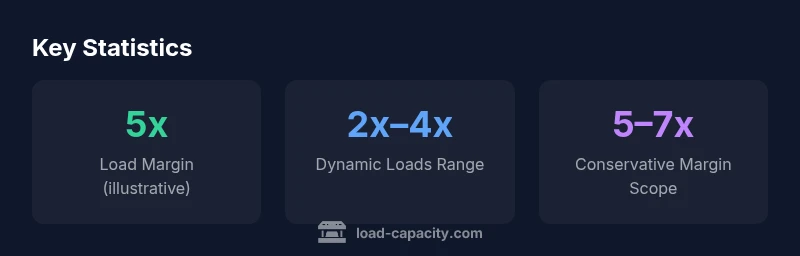

| Aspect | Guidance | Notes |

|---|---|---|

| Static load multiplier | 5x to 7x, context-dependent | Depends on material, joint details, and service life |

| Dynamic load multiplier | 2x to 4x, with safeguards | Consider impact duration and frequency content |

| Environmental factors | Account for temperature and corrosion | Degrade capacity over time unless protected |

| Verification methods | Calculations + testing | Use conservative inputs and document assumptions |

Quick Answers

What does a 5x load margin really mean in practice?

It means the design should withstand loads up to five times the anticipated operating load. This margin is used to address uncertainty in materials, workmanship, and external disturbances, and must be justified by standards, calculations, and tests.

A five-times margin means your design should handle five times the expected load, backed by standards and tests.

When should I apply the 5x rule?

Use the 5x rule in high-risk, safety-critical contexts or where consequences of failure are severe. In other cases, use a margin aligned with applicable standards and a formal risk assessment.

Use it in high-risk cases, but verify with standards and risk assessment for others.

How do I verify that a 5x margin is appropriate for my system?

Perform a capacity calculation, include worst-case load scenarios, and validate with testing or simulation. Ensure environmental and material degradation are included in the model.

Calculate, test or simulate worst-case loads, and include environment and aging effects.

What standards govern load margins and safety factors?

Standards vary by industry; consult relevant codes for your domain (e.g., structural, mechanical, and industrial safety guidelines). Use these as the baseline for any multiplier, including the 5x rule.

Check the industry codes for your domain to determine the baseline margins.

Can I reduce the margin if I add redundancy?

Adding redundancy can compensate for a smaller margin, but it does not eliminate the need for proper margins and verification. Document the redundancy strategy and its impact on risk.

Redundancy can offset margins, but you still need proper verification and documentation.

How should I communicate margins to non-engineers?

Translate margins into risk terms and performance outcomes, using visuals like charts and plain-language summaries to show how margins affect safety and reliability.

Explain margins in terms of risk and reliability with simple visuals.

“Margins are a design decision guided by standards and evidence. A 5x rule should be a documented choice, not a default, and must be justified with calculations and testing.”

Top Takeaways

- Start with a clear risk assessment and use the 5x rule only where justified

- Differentiate static and dynamic loads when applying margins

- Document assumptions, standards, and validation results

- Balance safety margins with cost, weight, and practicality

- Revalidate margins as conditions or materials change