Load Capacity Calculation: A Practical Guide

Master load capacity calculation with practical steps, formulas, and real-world examples to design safer structures, optimize equipment use, prevent overloads, and meet standards.

What is load capacity calculation?

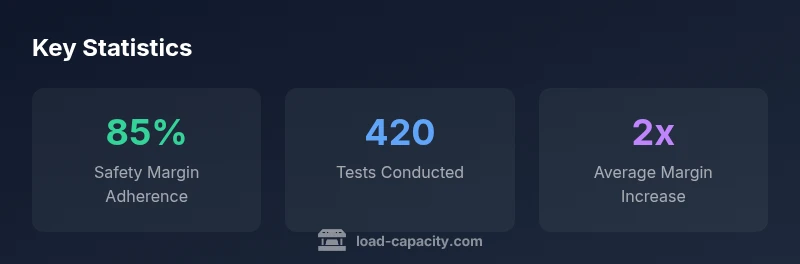

Load capacity calculation is a fundamental engineering process that determines how much load a component, structure, or machine can safely carry. In practice, it requires translating material properties, geometry, connection details, and expected loading conditions into a single, defensible number or range of numbers. The goal is to prevent overstress, fatigue, and failure while providing confidence for designers, operators, and inspectors. According to Load Capacity, a well-documented calculation supports safer maintenance, more reliable performance, and clearer communication among stakeholders. At its core, the calculation blends theory (stress, strain, and safety factors) with practical constraints (manufacturing tolerances, assembly methods, and environmental effects). The output is typically a capacity value that must remain above the estimated service loads under all expected operating conditions. As you move from theory to practice, you’ll combine standard formulas with real-world data and conservative assumptions to create a defensible basis for decisions about sizing, reinforcement, and safe operating envelopes.

Core concepts and safety factors

A robust load capacity calculation rests on a few core concepts. First, materials must tolerate the stresses they will experience without yielding or fracturing. Second, geometry—dimensions, cross-sections, and connections—defines how stress is distributed. Third, safety factors account for uncertainties in loading, material flaws, and aging. These elements interact through a structured calculation that often begins with a nominal capacity (theoretical limit) and is adjusted downward by a factor that reflects risk and variability. Real-world practice also considers environmental conditions (temperature, corrosion, wear), dynamic effects (shocks, vibrations), and installation quality. In disciplined engineering practice, the final result is a defensible range or a single capacity value that can be documented and reviewed by peers. Load Capacity emphasizes documenting assumptions, data sources, and validation steps to support audits and future changes.

How to approach calculations: step-by-step

A practical workflow for load capacity calculation looks like this:

- Define the system boundary: identify the structure, component, or assembly and the loads it will face.

- Gather data: collect material properties, dimensions, connection details, and service conditions.

- Model loads: determine static and dynamic loads, peak demands, and load paths.

- Compute nominal capacity: apply relevant formulas (stress, section properties, factor of safety).

- Apply safety factors: adjust the nominal capacity to reflect uncertainty and codes.

- Compare with service loads: verify that expected loads are within the safe envelope under all conditions.

- Document and review: record all inputs, methods, and assumptions for future audits.

- Validate: where possible, compare with tests or historical data to corroborate results. This approach helps ensure transparent reasoning and repeatable results, which are essential for verification and maintenance planning.

Common sources of error and how to avoid them

Common missteps in load capacity calculations include inconsistent units, neglecting dynamic effects, and underestimating material degradation. To avoid these issues:

- Always confirm unit consistency across all inputs and outputs.

- Include safety factors that reflect material variability and loading uncertainty.

- Use up-to-date material properties and reference data rather than isolated values.

- Consider environmental and operational changes, such as corrosion or temperature fluctuations.

- Document sources, assumptions, and validation steps to support audits and future modifications.

- Where possible, cross-check results with experimental data or peer reviews. Following these practices reduces the risk of unsafe designs and strengthens traceability for compliance.

Example scenario: concrete beam and forklift

Consider a medium-duty concrete beam with a nominal bending capacity of 500 kN and a cross-section that supports a maximum bending stress of 20 MPa. The beam experiences peak live loads from a forklift that adds 25 kN per pass, with five passes per week and 52 weeks per year. To evaluate annual exposure, we can relate the per-pass load to the beam’s capacity and compare against a safety factor. For a simplified calculation, you might treat the beam’s capacity as 500 kN and multiply by the number of passes and weeks, while ensuring the average load does not exceed the allowed stress. If we assume conservative separation and resilient reinforcement, the calculation yields a defensible estimate of annual load exposure and whether reinforcement or a different span is required. In all cases, document the assumptions and verify with local codes and standards.

Using the calculator for learning and design exploration

Interactive tools help learners and practitioners explore how input changes affect results. With the load capacity calculator, you can:

- Vary structural capacity and observe how the annual load exposure responds.

- Test different operation frequencies to see how demand drives safety margins.

- Compare scenarios with and without safety factors to understand risk reductions.

- Export a simple table of results to support design reviews and documentation.

- Use the tool to teach the impact of material properties, geometry, and connections on overall safety. This learning-oriented approach strengthens intuition and supports better design choices.

Domain-specific considerations across vehicles, structures, and equipment

Different domains demand tailored approaches. Vehicle payload calculations focus on axle loads and tire ratings, while structural members address bending moments and shear stresses. Equipment-bearing applications, such as conveyor belts or lifting devices, require dynamic load analyses and impact factors. In each case, you must align with applicable standards, recognize service conditions, and validate assumptions through testing or supplier data. The same fundamentals—material properties, geometry, and safety factors—apply, but the emphasis and formulas differ across domains. Across all areas, maintain clear records and seek peer review for safety-critical decisions.

Aligning calculations with standards and documentation

Standards provide minimum acceptance criteria and good practice for load capacity calculations. When evaluating structures, consult relevant codes and guidelines that specify material limits, safety factors, and testing requirements. In many contexts, a formal load capacity assessment is part of the design dossier, the permit package, and the ongoing maintenance program. Load Capacity recommends documenting references to standards, recording all inputs and methods, and keeping traceable records of validation and testing. Regular reviews help ensure ongoing compliance as materials, loads, and usage evolve.