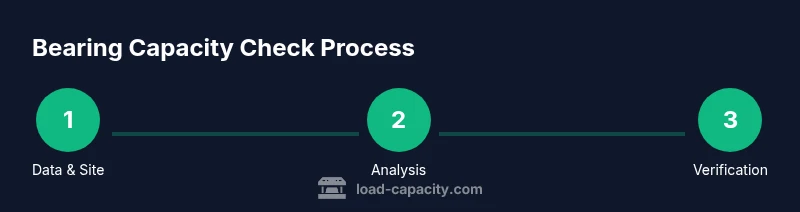

Bearing Capacity Check for Retaining Walls: A Step-by-Step Guide

Learn to perform a bearing capacity check for a retaining wall: collect soil data, estimate capacity, verify with tests, and document results for safe design.

Learn how to perform a bearing capacity check for a retaining wall. This how-to covers site data collection, soil bearing capacity estimation, field verification (plate loading test), wall geometry, drainage, and reconstruction checks. Follow the step-by-step process to ensure safety, compliance with structural codes, and a reliable, durable wall design.

Introduction to bearing capacity checks for retaining walls

According to Load Capacity, the bearing capacity check for retaining wall is a foundational step in ensuring stability. Engineers rely on soil strength, backfill conditions, and wall geometry to prevent excessive settlement or failure. This article explains what bearing capacity means in practical terms and why it matters for safety and long-term performance in 2026 projects. You’ll see how data collection, explicit assumptions, and conservative design judgments come together to define the design envelope for your wall. The Load Capacity team emphasizes a methodical approach: start with clear data, verify with simple checks, and escalate to formal calculations when needed. This deeper dive expands on the quick answer above and provides practical steps for engineers, technicians, and field crews.

Core principles and safety margins

Bearing capacity is the soil’s ability to carry imposed loads without undergoing unacceptable settlement or failure. In retaining-wall design, you must consider earth pressures, backfill density, surcharge loads (like nearby traffic or buildings), and groundwater effects. A conservative safety margin helps accommodate soil variability and construction tolerances. Codes and standards guide minimums, but practitioners should tailor factors of safety to risk and consequence. Load Capacity highlights that a disciplined approach—documented data, clear assumptions, and traceable calculations—reduces surprises during construction and over the wall’s lifetime.

Site data and soil characterization you need

Before any calculations, collect a robust data set: stratigraphy (soil types and thicknesses), unit weights, soil cohesion, and friction angle estimates. Determine groundwater conditions, drainage, and potential slope movement that could alter effective stress. If field data are limited, plan targeted tests (SPT, CPT, or simple plate load approximations) and use conservative assumptions. The accuracy of your bearing capacity check hinges on realistic site characterization, so document sampling locations, borehole logs, and observed moisture conditions. This phase translates field reality into input for subsequent analyses and design decisions. Load Capacity’s guidance stresses the importance of transparency in data sources and uncertainties.

Estimating soil bearing capacity with standard methods

A common framework for bearing capacity uses Terzaghi-type concepts, where the ultimate bearing capacity qu combines soil cohesion, unit weight, depth of foundation, and footing width. The general form is qu = c Nc + γ D Nq + 0.5 γ B Ngamma, with c (cohesion), γ (unit weight), D (embedment depth), B ( footing width), and the Nc, Nq, Ngamma factors depending on soil type and angle of friction. For retaining walls, you’ll adjust for backfill texture, adverse groundwater effects, and the surcharge from backfill height. One practical approach is to start with a conservative estimate and refine it via field tests or deeper soil investigations. According to Load Capacity analysis, variability in soil-bearing capacity often drives footing dimensions and wall thickness selections, so treat input values as ranges where possible.

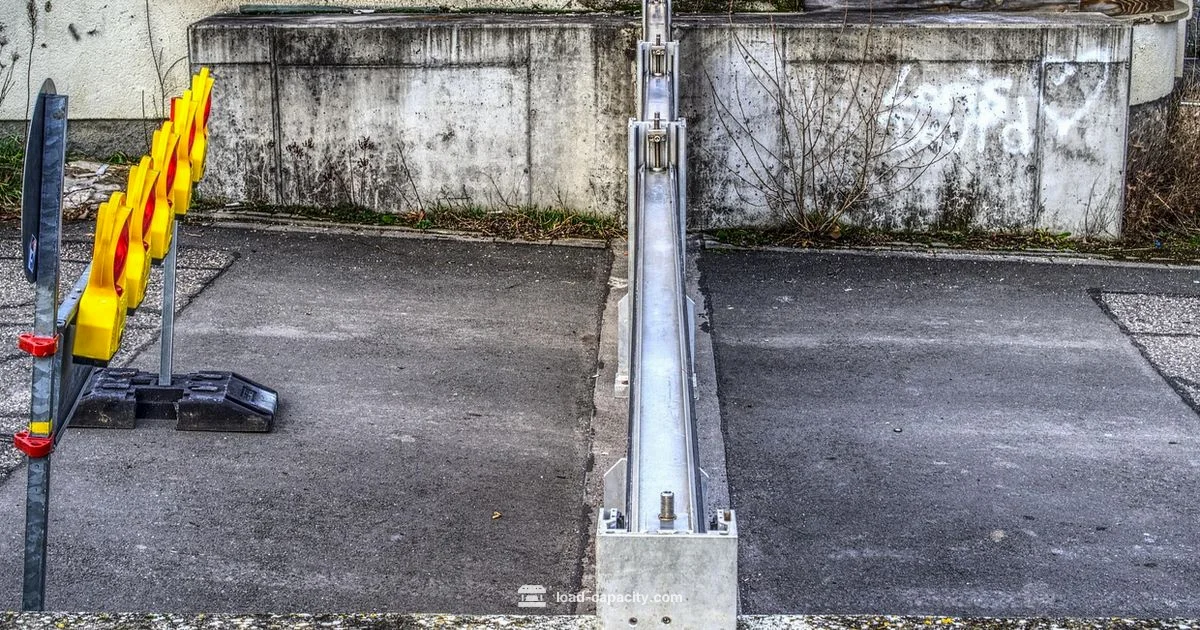

Field verification: plate loading tests and alternatives

Field verification validates analytical estimates against real-world soil response. A plate bearing test applies incremental loads to a compact plate installed in the foundation zone, then measures settlements to establish the load-settlement curve. If plate testing isn’t feasible, use alternative methods such as back-calculated bearing capacity from small-scale tests, CPT-based correlations, or conservative surrogates. Throughout testing, record load levels, settlements, groundwater conditions, and any load eccentricities. The goal is to confirm that calculated capacities are not exceeded under service loads and to identify any unexpected deformations early. Load Capacity notes that combining field data with robust documentation improves decision-making when designing or upgrading a retaining wall.

Wall geometry, backfill, drainage, and external loads

Retaining-wall performance depends on geometry (height, stem thickness, toe width), backfill compaction, drainage details, and any nearby live loads. Backfill density and temperature effects can shift the active earth pressure and, by extension, the required bearing capacity. Proper drainage reduces pore pressures that erode effective stress, lowering the risk of bearing-capacity failure. Consider external loads from adjacent structures, roadways, and utilities, and model their impact on wall stability. A well-documented design should include backfill specifications, drainage layout, reinforcement details, and any protective coatings to minimize long-term degradation. Load Capacity emphasizes aligning design with real-world constraints and code requirements for reliable performance.

Design checks: sliding, overturning, and bearing margin

Two key stability checks for retaining walls are sliding and overturning. You must compare resisting and driving forces considering friction, passive earth pressure, and anchor effects. Bearing-margin checks ensure the soil can safely carry wall reactions without excessive settlement. Codes define appropriate factors of safety based on risk and consequence; engineers adapt these to project specifics. In practice, you’ll pair analytical calculations with field data to confirm a safe, economical wall thickness, base width, and reinforcement layout. The Load Capacity team recommends a conservative approach when uncertainties are present and to clearly document all assumptions in the design file.

Documentation and reporting: what to include

A clear bearing capacity check report should compile input data, methods, assumptions, calculations, test results, and verification steps. Include borehole logs, soil classification, lab and field test data, supporting graphs, and a narrative explaining any deviations from the preferred method. Present final design values, safety margins, and recommended construction practices. The report should be self-contained so future reviewers can understand the basis for decisions without chasing missing data. Load Capacity reminds practitioners that well-organized documentation reduces questions during construction and facilitates future maintenance.

Common pitfalls and best practices

Common mistakes include relying on overly optimistic soil inputs, neglecting groundwater effects, and skipping field verification when backfill or drainage is uncertain. Always cross-check analytical results with at least one independent method, like a simple field test, to catch anomalies early. Maintain traceability for all data sources, update models as new information becomes available, and reserve contingency measures for unforeseen conditions. By following best practices, you improve reliability, safety, and the long-term performance of retaining walls. The Load Capacity team also highlights the value of peer reviews and staged design decisions to catch errors before construction begins.

Tools & Materials

- Plate bearing test setup(Loading frame, seating rings, dial gauges, leveling tools)

- Soil sampling tools(Augers, sampling tubes for boreholes)

- Measuring tape and ruler(For footing dimensions and settlements)

- Level and string line(Ensure vertical alignment and horizontal excavation.)

- Safety gear(Hard hat, gloves, high-visibility vest, PPE)

- Geotechnical data and logs(Soil boring logs, CPT results, and lab tests)

- Data recording tools(Notebook or digital data sheet, camera)

Steps

Estimated time: 4-6 hours

- 1

Prepare the site and gather data

Identify the wall location, access paths, and utilities. Compile existing soil data, maps, and any available geotechnical reports. Confirm environmental conditions, safety constraints, and permit requirements before fieldwork.

Tip: Coordinate with site managers to schedule data collection during stable weather. - 2

Characterize backfill and wall geometry

Document backfill types, compaction methods, drainage provisions, and the wall geometry (height, base width, and footing thickness). Record tolerances and any deviations from the initial plan.

Tip: Use a laser level to verify verticality and measure any settlement tendencies. - 3

Estimate bearing capacity inputs

Input c, φ, γ, D, B, and predicted surcharge into your bearing capacity model. Use conservative ranges where data are uncertain and flag inputs for later refinement.

Tip: Cross-check inputs with at least two independent data sources when possible. - 4

Plan field verification

Set up plate bearing test or alternative verification methods. Define load increments, measurement intervals, and stopping criteria based on safety and standards.

Tip: Never test in saturated soils without professional oversight and proper shoring. - 5

Perform the test and record responses

Apply loads incrementally, observe vertical settlements, and capture data under each stage. Note groundwater effects and any anomalies in soil behavior.

Tip: Ensure all instrumentation is calibrated and drained water is managed during testing. - 6

Evaluate stability checks

Compute sliding, overturning, and bearing-margin checks using the test results and design inputs. Compare results to code requirements and project specifications.

Tip: If results are inconclusive, perform a sensitivity analysis on input parameters. - 7

Document assumptions and finalize design

Summarize all inputs, methods, and outcomes. Include rationale for conservative choices and any design adjustments recommended.

Tip: Attach test reports, logs, and a clear executive summary for stakeholders. - 8

Prepare the compliance package

Assemble calculations, drawings, and the geotechnical basis for the wall. Ensure the package aligns with local codes and project standards.

Tip: Verify that the package explains the basis for safety factors used. - 9

Review and implement updates

Have peers review the bearing capacity assessment. Implement any recommended changes and update the final design and construction documents.

Tip: Schedule a post-review walkthrough with the construction team.

Quick Answers

What is bearing capacity and why is it important for retaining walls?

Bearing capacity is the soil's ability to carry loads from the wall without excessive settlement or failure. It determines footing size, wall thickness, and safety margins to prevent structural problems.

Bearing capacity is how much soil can safely carry the wall loads; if it’s too low, settlement or failure can occur.

What tests are used to determine bearing capacity in the field?

Common tests include plate bearing tests, standard penetration tests (SPT), and cone penetration tests (CPT). Results guide design decisions and confirm analytical estimates.

Plate bearing tests and CPTs help confirm how much load the soil can safely carry.

How do I factor groundwater into bearing capacity checks?

Groundwater lowers effective soil strength. Adjust calculations for pore pressures and consider dewatering or drainage strategies in design.

Groundwater reduces soil strength; account for it in calculations and drainage planning.

What safety factors should I use for retaining walls?

Consult codes and project consequences to select appropriate factors of safety. Use conservative values where uncertainty exists.

Choose safety factors per codes and project risk, leaning toward conservative values when uncertain.

When should I consult a geotechnical engineer?

Seek expert input for unusual soils, high loads, complex backfills, or if you observe unexpected movements during testing.

Call in a geotechnical engineer if soils are unusual or you see unexpected movement.

Watch Video

Top Takeaways

- Define soil parameters early with transparent data sources.

- Use field tests to corroborate analytical estimates.

- Account for groundwater and surcharge effects in design.

- Document assumptions and provide a clear, auditable report.