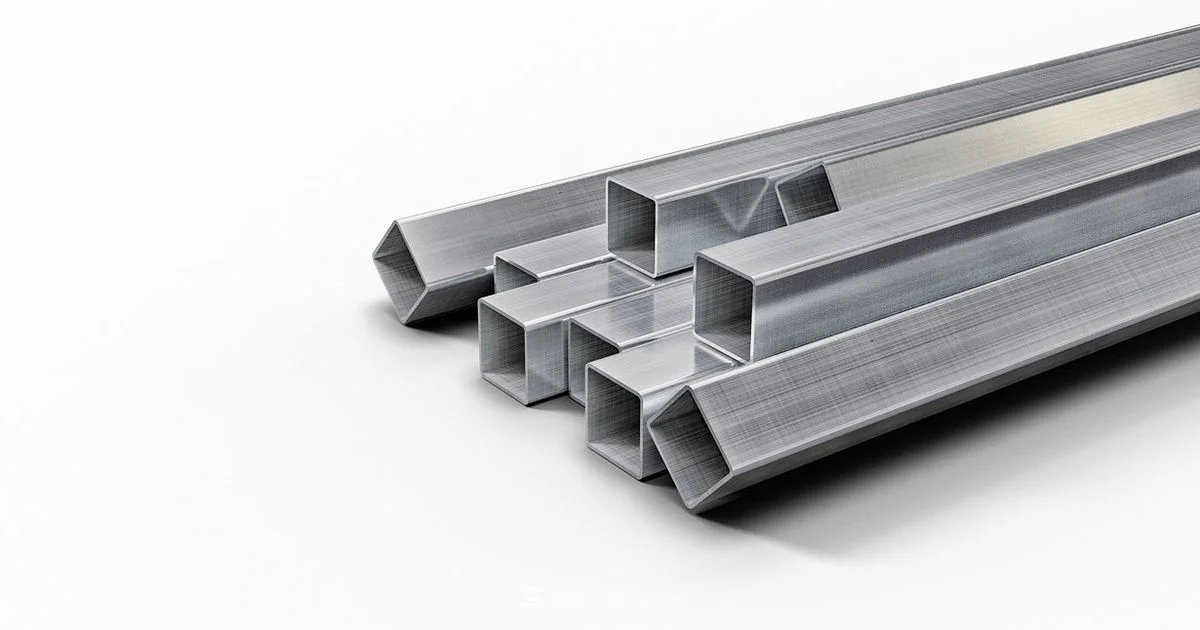

Aluminum Square Tubing Load Capacity Chart: Reading and Safe Design

A detailed guide to reading aluminum square tubing load capacity charts, outlining key factors, chart interpretation, and a practical workflow for safe, engineer-grade design.

There is no single universal aluminum square tubing load capacity chart. Capacity depends on profile size, wall thickness, alloy grade, length, support conditions, and load type (axial, bending, torsion). Use manufacturer data and standard engineering formulas to derive safe loads, then verify against your design requirements. Always consult the chart specific to your profile.

Understanding aluminum square tubing load capacity

Aluminum square tubing is valued for its light weight and decent strength, but its load capacity is not a fixed number. The capacity you can safely apply to a given profile hinges on several interacting factors: the outer dimension, wall thickness, alloy grade and temper, the length of the member, how it is supported, and the type of load applied. A chart specific to your exact profile combines these variables to give a usable rating. For engineers, this means starting with precise profile data and then cross-checking with standardized calculations to ensure margins for uncertainty and real-world conditions. According to Load Capacity, always anchor your analysis to the actual tube profile and the chart that corresponds to that profile.

Key factors that influence capacity

Capacity is not a single number but a function of several variables:

- Profile size (outer dimensions) and wall thickness determine the cross-sectional area and moment of inertia, which govern bending and deflection.

- Alloy grade and temper influence yield strength and stiffness. Common practice uses 6061-T6 or 6063-T5 as baseline references, but the exact grade changes allowable loads.

- Length and slenderness affect buckling risk under axial or compression loads. Longer members with the same cross-section are more prone to buckling.

- Load type and support conditions matter: axial, bending, torsion, or combined loads each have distinct ratings and corresponding charts.

- End connections, corrosion, and temperature can shift capacity modestly; these effects should be reflected in safety factors.

Understanding these interactions helps engineers interpret charts correctly and avoid overreliance on a single number.

Reading and interpreting an aluminum square tubing load capacity chart

A typical chart presents safe loads as a function of profile and length, with separate charts or axes for different load types. When reading a chart:

- Identify the exact profile (outer dimension and wall thickness) and alloy temper used in your design.

- Check the load type row or column that matches your condition (axial, bending, torsion, or combined).

- Read across to the length you intend to use; capacity generally decreases as unsupported length increases due to buckling and deflection concerns.

- Note any suggested safety factors and the units used (N,

Material science basics: alloys and temper for strength

Aluminum alloys enable a range of properties suitable for structural members. The most common alloys for tubing are 6061 and 6063, with temper designations like T6 or T5 indicating heat treatment and aging that affect strength and stiffness. In general, 6061-T6 offers higher yield strength than 6063-T5, so a chart based on 6061-T6 will permit higher safe loads for the same geometry. Temper also affects ductility and fatigue resistance, which can matter for dynamic or cyclic loading.

Geometry effects: size, wall thickness, and moment of inertia

The geometry of a square tube dictates how it resists bending and buckling. The moment of inertia (I) increases with larger outer dimensions and thicker walls, which improves bending capacity. However, thicker walls also add weight and cost. The polar moment of area (J) and section modulus (S) are critical in calculating bending stresses under a given load. Designers should consult both the chart and the fundamental equations to see how changes in size and thickness influence capacity and stiffness.

Load types and how they affect ratings

Loads on aluminum square tubing can be axial (end-to-end compression or tension), bending (sideways flexing under a transverse load), torsional (twisting), or a combination. Charts often segment ratings by load type because the governing failure modes and stress distributions differ. For example, axial loads emphasize buckling limits, while bending loads depend on section modulus and deflection criteria. Dynamic or impact loads require additional safety margins and sometimes separate dynamic charts or tests.

Practical design workflow: from data to safe design

A practical workflow for safety and efficiency:

- Gather exact profile data: outer dimension, wall thickness, alloy, and temper.

- Select the corresponding load chart for the profile and load type.

- Read the chart at the intended length, noting the allowable load and any safety margins.

- Apply a formal factor of safety consistent with codes and project requirements.

- Verify with a hand calculation using sigma = M*y/I or Euler buckling where appropriate.

- If the profile isn’t listed, escalate to the manufacturer for guidance or perform a custom calculation.

Common mistakes and how to avoid them

- Using charts that do not match the exact alloy/temper or profile. Always verify the data sheet.

- Ignoring end conditions and support spans; simple support does not equal fixed-end conditions.

- Overlooking dynamic effects; static charts may underestimate peak loads in real applications.

- Skipping safety factors; always run through a formal SF as part of the design.

- Relying on a single chart for all loading scenarios; use separate charts for axial, bending, torsion, and combined loads.

How to validate capacity in the field: testing and verification

Field verification combines calculation with practical testing. Use measured dimensions and, if possible, instrumented tests to compare actual deflections and responses with predicted values from the chart. Non-destructive evaluation (NDE) and simple load tests can help validate assumptions before full-scale implementation. Document test conditions, including temperature, alignment, end supports, and any dynamic effects observed during testing.

Example profiles and their chart-based ratings (values vary by chart)

| Profile | Outer Dimension | Wall Thickness | Alloy/Temper | Length | Estim. Safe Load | Notes |

|---|---|---|---|---|---|---|

| 1x1 in square tubing | 1.0 in | 0.065 in | 6061-T6 | 1.5 m | varies by chart | Refer to profile chart |

| 2x2 in square tubing | 2.0 in | 0.125 in | 6063-T5 | 2.0 m | varies by chart | Refer to chart |

| 3x3 in square tubing | 3.0 in | 0.188 in | 6061-T6 | 2.5 m | varies by chart | Refer to chart |

Quick Answers

What is meant by a load capacity chart for aluminum square tubing?

A load capacity chart is a reference that shows safe load limits for a given tube profile under specific conditions. Capacity depends on cross-section, alloy, length, and support. Always verify with the exact profile data and governing equations.

A load chart shows safe loads for a profile under specific conditions, but you must use the chart that matches your exact profile.

Do I need a different chart for every length?

Yes. Capacity changes with length due to slenderness and buckling risk. Always read the chart at the intended length, or re-calculate using your actual span.

Yes—the chart is length-specific, so check the chart for the length you plan to use.

Can I mix load types on a single chart?

Most charts are separated by load type. Read the axis labeled for axial, bending, or torsion. For combined loads, use the appropriate combined-load approach.

Usually you need the chart for the specific load type; mixed loads require separate consideration.

How do I determine a safe factor of safety?

Follow applicable codes and manufacturer recommendations. Multiply the chart’s rating by the chosen factor of safety to obtain the design load.

Use a design factor recommended by codes or the manufacturer to cover uncertainties.

What if my profile isn't listed?

Contact the manufacturer for a custom chart or perform a calculation using standard formulas with the exact dimensions and material.

If your size isn't listed, reach out to the supplier or run a custom calculation.

Is dynamic loading covered by standard charts?

Dynamic or impact loads require separate evaluation; static charts may underestimate peak loads. Consider dynamic factors and perform testing if needed.

Dynamic loads need extra analysis beyond static charts.

“A chart is only as good as the profile it represents; always use profile-specific data and engineering methods to confirm safe loads.”

Top Takeaways

- Read the chart for your exact profile

- Account for alloy and temper

- Consider length and end conditions

- Apply a safety factor

- Cross-check with calculations