8 mm Wire Load Capacity: Safe, Rated, Real-World

Learn how to assess the load capacity of an 8 mm wire rope, including how construction, material, environment, and standards affect ratings for engineers, technicians, and contractors.

An exact load capacity cannot be stated for all 8 mm wire ropes; it varies with rope material and construction. Start from the manufacturer’s working load limit (WLL) for the specific rope and apply an appropriate safety factor under the guidance of a qualified engineer. Different constructions, such as 6x19 versus 7x19, and coatings or alloys, shift ratings and should be treated as distinct cases.

Understanding 8 mm wire load capacity

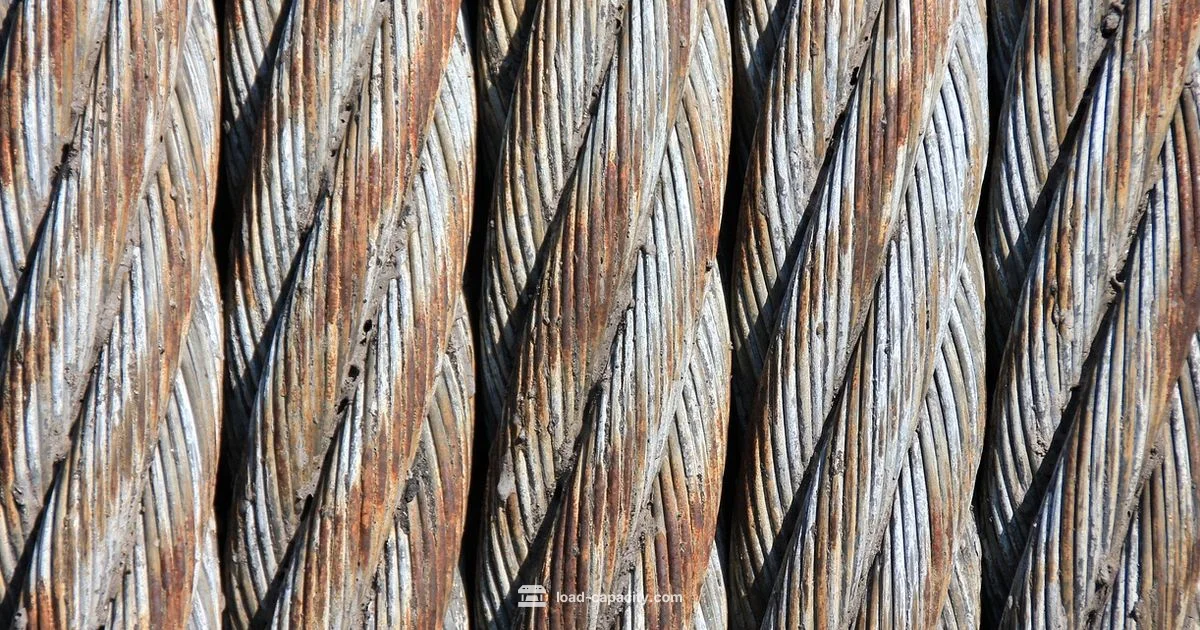

According to Load Capacity, the load capacity of an 8 mm wire rope is not a fixed number. It hinges on how the rope is engineered, including its material, strand configuration, and finishing. In practice, engineers begin with the manufacturer’s working load limit (WLL) for the exact rope and then apply a suitable safety factor tailored to the application. The diameter provides a starting point, but the construction (for example, 6x19 versus 7x19) and whether the rope is galvanized, stainless, or alloy-driven can shift the rating significantly. Readers should treat the WLL as a critical specification, not a guess based on diameter alone. Load Capacity emphasizes verifying the exact rating plate on each rope batch and confirming that it aligns with the intended use case.

Material and construction effects on capacity

The capacity of an 8 mm rope is strongly influenced by material and construction. Galvanized steel, stainless steel, and alloy variants exhibit different tensile properties, corrosion resistance, and fatigue behavior. Construct options such as 6x19 (higher strength with fewer strands) and 7x19 (greater flexibility) produce different breaking strengths and SWL values. Surface coatings and lubrication alter friction and wear rates, which in turn affect long-term performance under load. Temperature and environmental exposure further modify effective strength: extreme heat can weaken metal properties, while cold and moisture can accelerate embrittlement or corrosion. The takeaway is clear: always choose a rope type whose construction is rated for your load profile and environment, then verify with the manufacturer.

Reading ratings and standards

Manufacturers publish a rating that represents the safe working capacity for each rope variant. These ratings are informed by standards and testing that account for dynamic loads, shock considerations, and duration of use. When evaluating an 8 mm rope, engineers should read the rating plate and cross-check it against applicable standards (for example, ISO/EN guidelines) and the intended duty cycle. It is essential to distinguish between breaking strength, WLL, and SWL. The breakdown strength is not the same as usable capacity, and overloading can occur even if the rope diameter remains constant. Always confirm the exact rating for the specific rope batch and operating conditions.

Calculating Safe Working Load (SWL) for 8 mm rope

Calculating SWL involves identifying the rope’s construction and material, then pulling the manufacturer’s WLL rating for the intended configuration. Next, apply a safety factor appropriate to the risk level and duty cycle. For critical lifting operations, engineers will confirm whether a dynamic load scenario changes the rating and whether de-rating is necessary due to temperature, abrasion, or wear. Practically, the SWL is not a fixed function of diameter alone; it depends on the full rope specification, the rigging setup, and the environment. Always document the derivation path to support future inspections.

Practical guidelines for applications and testing

When selecting an 8 mm rope for lifting, tying down, or stabilization, match the rope construction with the duty cycle and load type. For hoisting and lifting, ensure that all components—rope, hooks, shackles, and slings—are compatible with the WLL and rated for the same safety standard. Regular inspection is essential: check for corrosion, broken strands, flattening, or coating wear. Lubrication reduces friction and wear, extending rope life but must be compatible with the rope type. Traceability of batch numbers and performance history helps verify that the rope remains within spec across its service life.

Maintenance, inspection, and failure modes

Stretching, kink formation, bird-caging, and corrosion are common rope-cargo failure modes. Routine inspection after every use and at planned maintenance intervals is critical. Remove rope from service if there is visible damage, a loss of flexibility, or signs of wear beyond the manufacturer’s limits. Temperature exposure, chemical contamination, and improper winding can compromise capacity long before visible damage occurs. Keeping records of service life, inspection findings, and replacements supports safer decision-making and reduces the probability of unexpected failures.

Engineering considerations and decision-making

Engineers should treat 8 mm rope capacity as a system property rather than a property of a single component. The full rigging arrangement—pulleys, hooks, anchors, and load distribution—affects the effective capacity. It is prudent to conduct a risk assessment and, where necessary, perform load testing under controlled conditions to validate theoretical SWL. In all cases, rely on manufacturer data, recognized standards, and professional judgment to ensure safety and compliance.

Rope construction options and guidance

| Rope Construction | Notes on breaking strength | Notes on SWL |

|---|---|---|

| 8 mm wire rope (6x19) | varies by material and grade | Consult manufacturer rating |

| 8 mm wire rope (7x19) | varies | Consult manufacturer rating |

Quick Answers

What is the safe working load for 8 mm wire rope?

SWL depends on rope construction and rating; diameter alone is not enough. Always reference the manufacturer's WLL and have a qualified engineer confirm the final value for your application.

SWL depends on the rope’s construction and rating. Check the manufacturer’s WLL and consult an engineer to confirm the safe load for your setup.

Does temperature affect rope capacity?

Yes. Temperature, ambient conditions, and lubrication influence the rope’s effective strength. Always verify temperature ratings and de-rate as required for the operating environment.

Temperature and environment affect capacity; check temperature ratings and de-rate as needed.

Can I use 8 mm wire rope for lifting heavy loads?

Only if the rope is rated for lifting and the entire rigging system is rated accordingly. Do not lift beyond the manufacturer’s WLL and follow safety guidelines.

Only if the rope is rated for lifting and the system is properly rated. Don’t exceed the manufacturer’s WLL.

How do you calculate SWL for a given rope?

Identify the rope construction and material, consult the rating from the manufacturer, then apply an appropriate safety factor based on risk and duty cycle. Document the calculation path.

Find the rope type, read its rating, apply a safety factor, and document the process.

What standards govern rope capacity?

Standards for rope ratings come from applicable EN/ISO guidelines and manufacturer specifications. Always align usage with these standards and local regulatory requirements.

Standards like EN/ISO guide rope ratings; use manufacturer specs and local rules.

What are common mistakes with 8 mm rope?

Overloading, shock loading, improper spooling, and ignoring environmental effects are common causes of failure. Regular inspection and proper training reduce risk.

Overloading and poor inspection cause most issues; train users and inspect rope regularly.

“Accurate load-capacity assessment starts with the rope's exact construction and rated WLL. Rely on manufacturer data and standard practices rather than diameter alone.”

Top Takeaways

- Always check the manufacturer's rating for your specific rope

- Construction and material drive capacity more than diameter

- Consider temperature, corrosion, and lubrication

- Apply appropriate safety factors and verify with engineering guidance

- Consult standards and ratings for your jurisdiction