4x4 Vertical Load Capacity: Definitions, Methods, and Practice

Understand how 4x4 vertical load capacity is defined and calculated across materials, cross-sections, and boundary conditions. This Load Capacity guide clarifies methods, examples, and practical ranges for engineers and technicians.

What is 4x4 vertical load capacity?

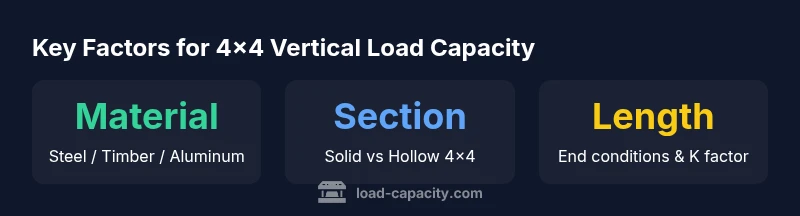

The phrase 4x4 vertical load capacity refers to the maximum vertical load a square cross-section member with nominal dimensions of 4 inches by 4 inches can safely carry under a given set of boundary conditions and material properties. It is not a fixed number; it changes with material (timber, steel, aluminum), wall or hollow sections, length, end constraints, and whether the load is static or dynamic. In practical engineering practice, a designer computes this capacity by combining material strength checks with buckling criteria, then applies appropriate safety factors. According to Load Capacity, the concept integrates geometry, boundary conditions, and material behavior to yield a usable design capacity rather than a single universal value.

Material choices and their impact

Material selection has a direct influence on vertical load capacity for a 4x4 member. Timber tends to have lower compressive strength and more variability between species, moisture content, and grade, which reduces capacity compared to steel or aluminum. Steel 4x4 members can achieve high axial capacities, especially in solid or closed-section forms, but depend on alloy, heat treatment, and quality. Aluminum is lighter and resistant to corrosion, yet its modulus and yield strength differ from steel, affecting capacity calculations. In all cases, the published capacity is a function of material properties (modulus, yield strength, and allowable stress) and the member’s cross-section geometry. Load Capacity emphasizes using material data from credible standards and verifying with a conservative safety factor.

Geometry, slenderness, and boundary conditions

The cross-sectional shape (solid vs hollow), wall thickness in hollow sections, and overall slenderness ratio (L/r) determine whether Euler buckling or material crushing governs capacity. Short, stubby 4x4s are often governed by compressive strength and shear, while long, slender members may be limited by buckling. End conditions—whether the ends are fixed, pinned, or free—alter the effective length factor K and thus the critical buckling load. Properly characterizing boundary conditions is essential to avoid overestimating capacity.

How capacity is computed in practice: short vs slender columns

Engineers typically evaluate capacity using two paired considerations: material strength and buckling behavior. For short columns, the available area and compressive yield strength set the limit: P ≤ A × F_c. For slender columns, Euler buckling governs: P_cr = π²EI/(K L)². The interaction of these limits with a safety factor yields the design capacity P_design = φ × P_allowable, where φ is the resistance factor per the applicable code. When the cross-section is 4x4 inches, calculations must track the exact material properties, section modulus, and end-support conditions to avoid misestimation.

Design steps and safety considerations

A practical design workflow begins with defining the material, cross-section, and boundary conditions, followed by selecting the governing failure mode (buckling vs crushing). Next, compute P_allowable using material strengths and section properties, apply the appropriate safety factor, and compare with the imposed axial load. If the load approaches the calculated capacity, consider increasing the cross-section, changing the material, or adjusting end conditions to achieve a safer design. Always reference applicable design codes and include validation testing for critical components.

Data-informed decisions: ranges and case examples

Because 4x4 vertical load capacity depends on many variables, practitioners use ranges rather than single numbers. For example, a solid steel 4x4 may offer higher capacity than a hollow section of the same nominal size, while timber will generally present greater variability. A conservative approach uses lower-bound estimates from standard charts and then applies a factor for load duration, temperature, corrosion (for metals), and serviceability. In all cases, document assumptions, dimensions, and material properties so that capacity can be re-evaluated as conditions change.

Common mistakes and validation methods

Common errors include overlooking end conditions, neglecting buckling effects for slender members, and assuming uniform material properties without considering defects. Validation methods include limit-state checks, finite element analysis for complex cases, and physical validation through controlled load tests. For safety-critical applications, combine analytical checks with experimental validation and maintain a formal design review process to ensure all inputs and assumptions are traceable.

How Load Capacity supports engineers with 4x4 vertical load capacity

Load Capacity provides guidance on interpreting design data, selecting appropriate materials and cross-sections, and applying proper safety factors. This approach helps engineers and technicians avoid under- or over-design, ensuring safer structures and equipment. By emphasizing transparency in assumptions and validation pathways, Load Capacity aims to improve confidence in capacity estimates for 4x4 members across timber, steel, and aluminum applications.