Understanding Super Carry Load Capacity

A data-driven guide to super carry load capacity across vehicles, decks, and machinery. Learn methods, safety margins, measurement approaches, and best practices for robust capacity verification in engineering projects.

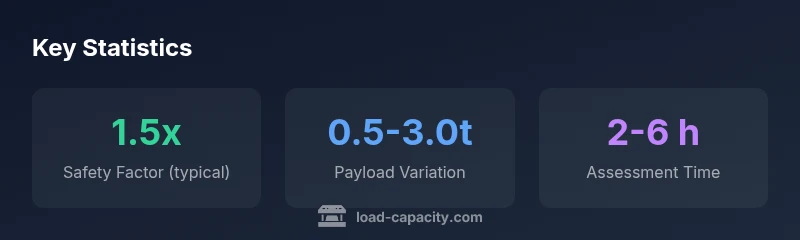

The concept of super carry load capacity blends rated payloads with conservative safety factors to estimate what a system can reliably carry under real conditions. In practice, engineers compare static ratings to dynamic loads, account for environmental factors, and apply margins to prevent overloading. This guide covers methods, pitfalls, and best practices for robust capacity estimation.

What "super carry load capacity" means in practice

In engineering discussions, super carry load capacity refers to the upper limit of what a system can reliably carry under anticipated operating conditions, when you factor in safety margins and variability. It is not a single number printed on a data plate; rather, it is a derived value that accounts for the weakest link in the chain—whether it is the material, the geometry, the connection, or the environment. For a crane, the super carry load capacity might depend on reach and angle; for a trailer, on axle spacing and tire ratings; for a structural deck, on support spacing and subgrade. The value you actually apply in design is the smallest credible capacity among all subsystems, further reduced by a conservative safety factor to cover uncertainties such as dynamic effects, weather, and wear. Practically, engineers use this concept to avoid overload, reduce risk, and ensure regulatory compliance across projects.

To put it plainly, the goal is to avoid a situation where a load exceeds what the weakest component can safely withstand. The concept is especially critical when multiple subsystems interact, such as a vehicle towing a heavy load over uneven terrain or a bridge deck subjected to transient traffic loads. By embracing conservative margins, organizations can protect personnel, improve reliability, and simplify compliance with industry standards. Real-world decisions—from component selection to maintenance planning—rely on this integrated view of capacity rather than isolated ratings.

Examples of load-capacity scenarios across common systems

| Scenario | Typical Range | Notes |

|---|---|---|

| Vehicle payload (gross) | 0.5-3.0 tons | Depends on model/year |

| Deck or floor loading (per area) | 100-700 kg/m2 | Structure grade matters |

| Trailer capacity | 2-15 tons | Hitch/axle limits |

| Forklift capacity | 1-5 tons | Lift vs reach |

Quick Answers

What exactly is 'super carry load capacity' and why does it matter?

It is not a single fixed number; it reflects the upper bound derived from rated payload, bearing limits, and safety margins. It varies with configuration and service conditions, guiding safe design and operation.

It’s the upper bound on what you can carry safely, and it changes with how the system is used.

How do I estimate capacity for a new design?

Start with the manufacturer’s ratings, verify structural bearing limits, and apply a conservative safety factor. Where possible, validate with analysis and physical testing to confirm assumptions.

Begin with ratings, add safety margins, and validate with tests.

What factors influence capacity in practice?

Material strength, geometry, loading rate, environmental conditions, and the integrity of connections are the dominant influencers of effective capacity.

Strength, shape, speed, environment, and supports matter most.

Can capacity change after installation or use?

Yes. Wear, deformation, corrosion, and fatigue can reduce capacity, so periodic reevaluation and maintenance are essential.

Yes, wear can lower capacity; reassess regularly.

What are common mistakes to avoid when assessing capacity?

Relying solely on nominal ratings, ignoring dynamic effects, and skipping validation testing can lead to unsafe or overly conservative designs.

Don’t rely only on nominal ratings; test and validate.

“Robust capacity estimation combines theoretical models with validated testing and conservative margins to deliver reliable results across configurations.”

Top Takeaways

- Define system scope before calculating capacity

- Apply conservative safety factors to account for uncertainty

- Compare static ratings with dynamic loading and environmental effects

- Document methodology for auditability and traceability

- Communicate findings clearly to stakeholders to support decision-making