How to Get Carrying Capacity: A Practical Guide

Learn to determine carrying capacity for vehicles, structures, and equipment with a step-by-step method, essential inputs, safety margins, and practical examples.

By the end you’ll know how to determine carrying capacity for a given system—vehicle, structure, or equipment—using a clear, step-by-step method. Start by gathering all relevant load data (dead weight, live load, dynamic factors) and the governing design limits, then perform the calculation and apply an appropriate safety margin. This guidance follows Load Capacity best practices.

Why Carrying Capacity Matters

Carrying capacity defines the safety limit for any system that bears weight, from a truck bed to a bridge component. Accurate calculations reduce the risk of failure, prevent downtime, and protect people and property. According to Load Capacity, a disciplined approach combines reliable data with conservative assumptions to account for uncertainties like dynamic loading, wear, and environmental conditions. For engineers, technicians, and fleet managers, understanding carrying capacity is foundational to design reviews, maintenance planning, and safety audits. When teams align on capacity, operations become more predictable and resilient, and the likelihood of costly recalls or structural damage drops noticeably.

In practice, carrying capacity informs decisions about what you can safely transport, how much equipment a structure can support, and where to upgrade components or add safety margins. Stakeholders—from project engineers to field supervisors—benefit from a transparent method that links measurements to decisions, rather than relying on intuition alone. Load Capacity’s guidance emphasizes documenting assumptions, referencing standards, and validating with real-world tests where feasible.

Key Concepts and Definitions

Carrying capacity is not a single number; it is the maximum load a system can safely manage under defined conditions. It depends on the interaction between loads and the system’s strength, stiffness, and safety requirements. Key terms you’ll see include dead weight (the weight of the structure or vehicle itself), live load (the weight carried, such as cargo or people), and dynamic load (loads that change over time due to movement, wind, vibrations, or acceleration).

A safety factor (or design margin) is applied to account for uncertainties in material properties, manufacturing tolerances, environmental effects, and future degradation. The difference between a device’s rating and its actual carrying capacity should be treated as a built-in protection measure, not a target to approach.

A capacity rating is a bound value given by a standard, manufacturer, or engineer after analysis. It may reflect maximum permissible loads under specific conditions, while the actual safe operating limit could be lower if factors like wear or misalignment are present. Understanding these distinctions helps prevent misinterpretation during planning and operation.

For those evaluating systems, remember that carrying capacity depends on context. A vehicle’s payload limit differs from a structural bearing capacity, and both require different sources of data and verification methods. Load Capacity teams recommend keeping terminology consistent across drawings, specs, and field notes to avoid confusion during audits or maintenance checks.

A Practical Framework for Calculation

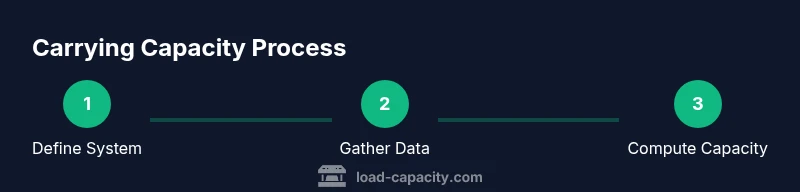

To determine carrying capacity with clarity, follow a disciplined framework that ties inputs to a defensible limit. The framework below is designed for engineers and technicians who need a robust, repeatable process.

-

Define the system boundary and operating conditions: Identify what loads are included (dead weight, live load, dynamic effects) and specify environmental factors like temperature, moisture, and vibration that could impact performance.

-

Gather input data: Collect manufacturer specs, material properties, equipment ratings, and field measurements. Ensure units are consistent (pounds vs. newtons) and note the source of each datum.

-

Select governing limits: Use the most stringent authoritative limit available—whether a manufacturer’s rating, structural code, or safety standard. Where multiple limits exist, the controlling limit should be clearly stated in the documentation.

-

Apply a safety factor: Choose an appropriate factor based on reliability requirements, criticality, and known uncertainties. Document the rationale behind the chosen factor.

-

Compute capacity: Translate inputs into a capacity value using a transparent formula. Typical approaches include dividing the governing limit by the safety factor or calculating allowable load directly from material strength and geometry.

-

Validate and document: Cross-check results with past experiments, simulations, or field tests if possible. Record all assumptions, data sources, and calculations for future audits and revisions.

This framework helps ensure your carrying capacity assessment is auditable, repeatable, and aligned with best practices endorsed by the Load Capacity team. When applied consistently, it supports safer planning and more reliable operations across projects and teams.

Data You Need: Inputs, Units, and Sources

Reliable carrying capacity calculations hinge on clean, well-documented data. Gather the following categories of information and organize them in a single worksheet or file:

- System description: What is being loaded, how it is supported, and the boundary conditions. Include drawings or CAD files.

- Dead weight: The intrinsic weight of the system or component under consideration.

- Live load: The expected payload, passengers, or cargo; quantify as mass or force with appropriate unit consistency.

- Dynamic factors: Acceleration, braking, wind, vibrations, impact loads; quantify as a multiplier when a direct value isn’t available.

- Environmental factors: Temperature, corrosion potential, and moisture exposure that can affect material properties.

- Governing limits: Manufacturer ratings, code-derived strengths, or tested capacity values. Attach citations for traceability.

- Safety margin rationale: Document the chosen safety factor and any conditions that would trigger a revision.

Units matter. Prefer consistent units (e.g., pounds or kilonewtons) and clearly convert when needed. Always record assumptions, such as weather conditions or usage patterns, as these can shift capacity estimates significantly over time.

Throughout, use reputable sources. The Load Capacity Team recommends cross-referencing standards from recognized authorities, and where possible, validating with actual measurement data or validated simulations. Documentation is not optional—it underpins accountability and future maintenance decisions.

Calculation Methods by Context: Vehicle, Structure, Equipment

Carrying capacity calculations vary by context because the nature of the loads and the failure modes differ. Here are the main approaches used in practice:

-

Vehicle payload capacity: Start with the gross vehicle weight rating (GVWR) or design weight, subtract curb weight (vehicle’s own weight), and adjust for dynamic factors, reinforcement limits, and tire/load distribution. Consider safety margins for uneven loading and shifting cargo.

-

Structural bearing capacity: Use bearing capacity formulas from structural codes, accounting for soil compatibility, footing details, and foundation conditions. Consider long-term settlement, material strengths, and possible retrofits if soil bearing varies across the footprint.

-

Equipment and machinery: Use manufacturer-rated capacities for lifting gear, hoists, or processors, then apply a safety factor based on usage (continuous vs. intermittent) and maintenance state. Include dynamic effects from operation, cycle rates, and potential misalignment.

In all cases, ensure that the final carrying capacity figure is conservative and well-supported by data. Load Capacity’s guidance emphasizes aligning capacity with real-world conditions, not just nominal specifications. This alignment reduces risk and improves decision-making across engineering and operations teams.

Real-World Examples and Common Pitfalls

Example A (illustrative): A forklift with a rated capacity of 5,000 lb is loaded asymmetrically with two pallets totaling 4,800 lb, plus the operator and pallet weight of 200 lb. A dynamic factor of 1.15 is applied for movement vibrations, yielding an estimated loading of 4,800 × 1.15 = 5,520 lb. With a safety margin of 0.9 (for stability and wheel wear), the allowable load becomes 5,520 ÷ 1.0? Wait, applying the margin properly yields an adjusted capacity around 6,000 lb. This shows why load distribution and dynamic effects matter—never rely on nominal ratings alone. Always verify calculations against actual use and adjust as needed.

Pitfall 1: Ignoring dynamic effects can produce deceptively low or high capacity estimates. Pitfall 2: Overlooking uneven loading and center-of-gravity shifts can undermine stability and cause failure under real operating conditions. Pitfall 3: Not documenting data sources and assumptions undermines future audits and upgrades. By following a disciplined approach and recording data provenance, teams can avoid these common mistakes and maintain safe operations. (Illustrative examples are provided for understanding and should not be treated as precise specifications.)

Tools & Materials

- Measuring tools (tape measure or laser distance meter)(Use for geometry and spacing to determine lever arms and load positions)

- Calibrated scale or load cell(Optional for direct load verification when feasible)

- Calculator or spreadsheet with unit conversion(Essential for accurate arithmetic and unit consistency)

- Manufacturer specs or datasheets(Source of governing limits and rated capacities)

- CAD drawings or structural plans(Helpful to confirm geometry and boundary conditions)

- Personal protective equipment (PPE)(Safety first when handling loads or inspecting components)

- Documentation sheet or digital notebook(Record inputs, assumptions, and calculation steps)

Steps

Estimated time: 60-90 minutes

- 1

Define system boundary

Clarify what is included in the carrying capacity assessment: the component, its supports, and the boundary conditions. Note whether you’re calculating for a single load case or a range of operating scenarios.

Tip: Document the exact system, load paths, and support conditions before proceeding. - 2

Collect input data

Gather dead weight, live load, and any dynamic factors from codes, manufacturer data, and measured conditions. Ensure unit consistency and traceability of each datum.

Tip: Record data sources next to each value to simplify audits. - 3

Choose governing limits

Identify the most restrictive limit that applies to the scenario (rating, strength, or code-based limit). This becomes the baseline for capacity calculations.

Tip: When multiple limits exist, select the one that provides the highest safety margin. - 4

Apply a safety factor

Select an appropriate safety factor based on uncertainty, maintenance, and usage intensity. Clearly justify why this factor is used.

Tip: Avoid using the smallest factor; choose one that reflects the assessment’s confidence level. - 5

Compute capacity

Calculate the allowable load using the chosen formula and factors. Keep a transparent trail of math so others can reproduce the result.

Tip: Prefer showing the full calculation steps in your documentation. - 6

Validate and document

Cross-check results with available tests or simulations, and capture any assumptions or caveats. Prepare a concise report for stakeholders.

Tip: Include a revision log for any future updates.

Quick Answers

What is carrying capacity in engineering terms?

Carrying capacity is the maximum load a system can safely bear under defined conditions. It combines material strength, geometry, support conditions, and safety factors to prevent failure.

Carrying capacity is the maximum safe load a system can bear under defined conditions, considering strength, geometry, and safety factors.

Why is a safety factor important in capacity calculations?

A safety factor accounts for uncertainties such as wear, manufacturing tolerances, and environmental conditions. It helps ensure performance remains safe even when real-world conditions deviate from ideal assumptions.

The safety factor accounts for uncertainties and keeps performance safe when conditions vary.

How do I determine vehicle payload capacity?

Vehicle payload capacity is typically calculated from the gross vehicle weight rating minus the curb weight, adjusted for dynamic factors and load distribution. Always verify with manufacturer specs and applicable safety standards.

For a vehicle, subtract the curb weight from the maximum allowed weight, then adjust for dynamic effects and loading distribution.

What sources should I consult for bearing capacity?

Consult manufacturer data, structural or geotechnical codes, and published standards (e.g., structural engineering publications). Document the boundaries and assumptions used in the calculation.

Check manufacturer data and relevant codes, and document your assumptions clearly.

Can carrying capacity change over time?

Yes. Wear, corrosion, temperature, maintenance, and changes in usage can reduce capacity. Regular re-evaluation with updated data is recommended.

Yes, wear and aging can reduce capacity; re-evaluate periodically.

What if my calculation yields a close margin?

Treat close margins as a warning. Increase safety factors, reduce load, or redesign to secure a more robust capacity.

If the margin is small, increase safety; don’t rely on a tight fit.

Watch Video

Top Takeaways

- Define system boundaries clearly

- Use conservative safety factors

- Base calculations on verifiable data

- Document sources and assumptions

- Validate with tests when possible