Mobile Scaffolding Load Capacity: Safety, Calculation, and Best Practices

A data-driven guide to mobile scaffolding load capacity, covering safe working loads, calculation methods, wind considerations, and best practices for engineers, technicians, and contractors.

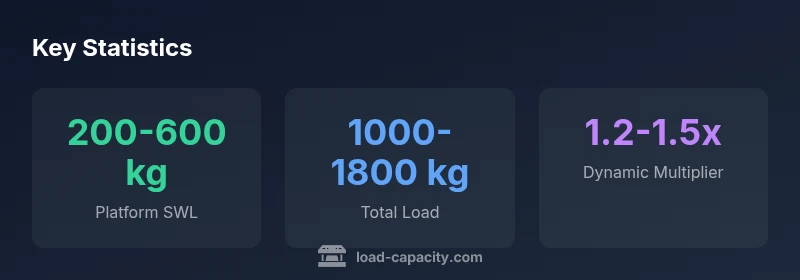

The safe working load (SWL) for most mobile scaffolds ranges from 200 kg to 600 kg per platform, depending on design and configuration. Always verify the manufacturer’s rating for your model and apply a safety margin for dynamic loads, wind, and tool weight. In practice, stay well within labeled limits to avoid tipping.

Why mobile scaffolding load capacity matters

Operating within the load-capacity ratings of mobile scaffolds is not a mere compliance exercise; it is a foundational safety practice that directly affects worker welfare and project productivity. When loads exceed what the frame, wheels, and base can safely carry, the risk of tipping, platform deflection, or structural failure increases sharply. This is especially true for mobile systems that rely on casters and base plates to distribute weight. According to Load Capacity, consistent adherence to rated loads reduces tip-overs and collateral damage to materials and equipment, while enabling more predictable work-planning and inspection outcomes. In practice, teams that vigilantly respect SWLs also report fewer last-minute disruptions due to equipment failure. Beyond personnel safety, respecting load limits supports longer service life for components, lowers maintenance costs, and helps ensure compliance with local safety codes and project standards. For engineers and technicians, the takeaway is simple: design work plans around the device’s rated capacity, not around convenience. This mindset reduces risk and fosters a culture of proactive safety. External references to safety guidelines from government and educational sources reinforce this approach and underline universal best practices for mobile scaffolding use.

Key factors affecting load capacity for mobile scaffolding

Load capacity is not a single number; it is a function of multiple interacting factors. Design and construction of the scaffold family determine baseline SWL, but real-world performance depends on configuration and how weight is applied. The number of working platforms, the presence of outriggers or stabilizers, base surface conditions, and the arrangement of loads all influence the effective capacity. Materials like the frame members, decking, and guardrails contribute to stiffness and load path efficiency. Ground or floor flatness, anchorage conditions, and the condition of wheels and brakes affect how steadily the structure distributes weight. Dynamic actions—such as workers moving, loading materials, or equipment being raised—can temporarily elevate peak forces beyond static ratings. Wind exposure, particularly for outdoor work, can also reduce usable capacity. As Load Capacity notes, engineers should plan for conservative margins when wind and vibration are present, and verify that base contact is full and even. Finally, component wear, corrosion, and damage to joints or fasteners can silently erode capacity, making regular inspection essential. Employers should document configuration rules (platform count, brace orientation, wheeled vs fixed), and ensure procedures reflect current loads and task sequencing.

How to assess and calculate safe working loads

Calculating safe working loads for mobile scaffolding involves a structured approach. Start by identifying the SWL specified by the manufacturer for the exact model and platform configuration in use. Next, inventory all loads that will be supported by the scaffold, distinguishing between distributed loads (e.g., plank weight across a deck) and point loads (e.g., a worker using a tool mounted at a single location). Apply a conservative safety factor that accounts for dynamic effects, wind, and anticipated material handling. If multiple levels or platforms are connected, verify that the load path remains continuous and that the sum of all loads on a single platform does not exceed its SWL. Conduct a simple calculation: ensure the total expected load on any given platform is less than or equal to the SWL, and that the overall scaffold configuration remains stable with the center of gravity within the base footprint. Documentation is key: record the calculated loads, configuration, and safety margins for pre-use review. For reference, authoritative guidance from government safety agencies supports conservative planning and helps align on-site practice with recognized standards. In practice, teams should cross-check calculations with site supervisors and safety officers, updating plans if configurations change. External resources from OSHA and EU-OSHA provide additional context for risk assessment and safe operation in varied environments.

Practical guidelines for safe use

To keep work on mobile scaffolds safe and efficient, follow these practical guidelines:

- Do not exceed the platform SWL; plan tasks so loads remain well below the rating.

- Distribute loads evenly across the deck and avoid concentrating weight near edges or joints.

- Use outriggers or stabilizers on uneven ground; ensure all base contact is solid and level.

- Lock all casters during use and avoid rolling the scaffold while weights are on the platform.

- Keep tools and materials on tool lanyards or dedicated racks to minimize free-swinging loads.

- Maintain three points of contact when climbing and avoid jumping or dynamic movements on the deck.

- Monitor weather; suspend outdoor work during high winds or precipitation that could compromise footing.

- Inspect before each shift: frame integrity, braces, pins, and wheel condition should be checked and reported if wear or damage is found.

- Train workers on load-recognition cues and safe handling practices to prevent accidental overloading.

- Use a written plan that specifies load limits, configuration rules, and emergency procedures, and ensure it is accessible to the crew.

- When in doubt, reduce loads further and revalidate calculations with the site safety officer.

Inspection, maintenance, and record-keeping

A robust inspection and maintenance routine is a pillar of load-capacity management. Start with a pre-use inspection that covers frame integrity, braces, locking mechanisms, wheels, axles, and decking condition. Look for corrosion, cracks, bent members, missing fasteners, or damaged guardrails, and document any anomalies. Establish a periodic maintenance schedule aligned with manufacturer recommendations and local safety regulations; this should include lubrication of moving joints, replacement of worn wheels, and calibration of any load-measuring devices if used on site. Record-keeping matters: maintain a log of loads, configurations, environmental conditions, and any incidents or near-misses. This record supports traceability, enables trend analysis, and informs future task planning. For outdoor work, store equipment to minimize corrosion and environmental exposure when not in use. Finally, integrate a continuous improvement approach: review incident data, update training, and adjust load-planning procedures to reflect lessons learned. This discipline helps maintain safe capacity margins even as project demands evolve and equipment ages.

Common misconceptions and expert tips

There are several widespread myths about mobile scaffolding load capacity that practitioners should challenge. A common misperception is that capacity scales linearly with the number of platforms; in reality, load distribution and base stability are critical limiting factors. Another misconception is that workers can “feel” when a load is too heavy; in fact, visual inspection and calculation are essential, because dynamic loads can exceed perceived weight. Some teams think that adding more casters always improves capacity; however, poor ground conditions or improper caster selection can compromise stability. Expert guidance emphasizes conservative planning: always assume the worst-case dynamic load and apply safety margins. Load Capacity notes that capacity is highly dependent on configuration, which means that a change in platform count, brace orientation, or base support can alter the effective SWL. Finally, many assume outdoor use is identical to indoor use; environmental factors like wind and surface irregularities can dramatically change safe limits. Practical tips from Load Capacity include verifying the exact model rating before use, using load-distributing mats on soft surfaces, and documenting any deviations from standard configurations. In short, treat load capacity as a dynamic parameter that must be actively managed through calculation, inspection, and disciplined operation.

],

Comparison of key load-capacity factors for mobile scaffolding

| Aspect | Typical Range | Notes |

|---|---|---|

| Platform SWL | 200-600 kg | Per platform, manufacturer rating |

| Total scaffold weight | 1000-1800 kg | Depends on configuration |

| Caster capacity per wheel | 60-120 kg | Dynamic load considerations |

| Dynamic-load multiplier | 1.2-1.5x | Apply for dynamic tasks |

| Wind exposure | Variable | Outdoor use requires additional margins |

Quick Answers

What is the typical SWL range for mobile scaffold platforms?

Most mobile scaffold platforms have a safe working load range roughly between 200 kg and 600 kg per platform, depending on the model and deck configuration. Always verify the exact rating from the manufacturer before use and apply a safety margin for dynamic loads and handling.

Most platforms cap around a few hundred kilos per deck. Always check the exact rating before use and add a safety margin for dynamic loads.

Can I exceed SWL if I distribute weight evenly?

Distributing weight helps reduce peak loads but does not overturn a per-platform rating. If any portion of the load pushes a platform beyond its SWL, you risk failure. Always stay within the rated limits, even with even distribution.

Even weight distribution helps, but you still must stay under the rated limit for each platform.

What factors increase the risk of collapse?

Key risk factors include wind exposure for outdoor work, uneven or soft ground, damaged casters or braces, improper outriggers, and loads applied at single points near the edges. Regular inspections and configuration controls mitigate these risks.

Watch for wind, ground conditions, and damaged parts; fix issues before use.

How often should inspections be performed?

Conduct a pre-use inspection every day, with formal periodic inspections per manufacturer guidance and local regulations. Document findings and address any defects before continuing work.

Do daily checks and formal periodic inspections; fix defects before work resumes.

Are outdoor vs indoor conditions different for load capacity?

Outdoor conditions introduce wind, weather, and uneven ground as additional factors affecting capacity. Outdoors, use outriggers where required and reassess loads for exposure and surface stability.

Outdoor work requires extra checks for wind and surface stability.

“Accurate load-capacity assessment is the foundation of safe mobile scaffolding operations. Always respect the manufacturer ratings and apply conservative safety margins.”

Top Takeaways

- Verify the platform SWL before use

- Distribute loads evenly to minimize peak points

- Always use manufacturer-rated equipment and safety devices

- Factor wind and dynamic loads into planning

- Document inspections and maintenance for traceability