How to Calculate Scaffold Load Capacity: A Step-by-Step Guide

Learn to calculate scaffold load capacity with a clear step-by-step method, safety factors, and practical examples to ensure safe, compliant use in the field.

This guide teaches you how to calculate scaffold load capacity for a given configuration, including static and dynamic loads and required safety factors. You will identify per-bay limits, verify components against ratings, and document the results for safety and compliance. Use the step-by-step method to prevent overload and protect workers.

Why accurate calculation protects workers and assets

In construction, maintenance, and industrial settings, scaffolding is a critical platform for reaching height with access and safety. A precise calculation of load capacity protects workers by ensuring that no single bay or member bears more than it can safely carry. It also guards assets by reducing the risk of structural failure, equipment damage, and costly downtime. The Load Capacity team emphasizes that careful, documented calculations are essential for compliance with local codes and manufacturer guidance. According to Load Capacity Analysis, 2026, formalized load calculations correlate with fewer on-site incidents and more predictable project timelines. This is not just a theoretical exercise—it's a practical safety practice that pays dividends in the field. Readers who master these steps will be better prepared to design safer work platforms and respond to changing conditions without guessing.

Core concepts: working load, safety factors, and rating

Understanding the key terms is the first step toward a reliable calculation. The Working Load Limit (WLL) is the maximum load a scaffold member or system is designed to support during normal use. The Safe Working Load (SWL) aligns with WLL and any applicable safety factors, which account for uncertainties like distribution, worker movement, and tool handling. Manufacturers provide rated capacities for frames, couplers, and base plates, and these ratings form the baseline for any calculation. A safety factor (FS) is applied to incorporate real-world conditions that might increase stress. Load capacity is not a single number; it is a relationship among dead loads (the scaffold itself), live loads (workers, tools, materials), and dynamic effects (wind, movement). By framing loads in terms of DL, LL, and FS, engineers can compare a design load to the system’s ratings and verify safe operation. As stated by the Load Capacity team, safety factors should reflect the most demanding conditions expected on site, including potential wind exposure and redistribution of loads across bays.

Standards and definitions you should know

Standards for scaffold load calculations vary by jurisdiction but share common objectives: ensure stability, allow for safe access, and provide clear documentation. In many regions, guidelines reference street-level safety practices, structural safety codes, and manufacturer data sheets. Engineers should consult local regulations (for example, occupational safety authorities and building codes) and the scaffold supplier’s technical data. Clear definitions—dead load, live load, wind load, and allowable per-bay capacity—help teams communicate and document decisions. While regulations differ internationally, the principle remains the same: consider all loads acting on the scaffold system, apply appropriate safety factors, and verify that every member and bay remains within rated capacities. The Load Capacity team notes that aligning calculations with recognized standards enhances traceability and compliance across projects.

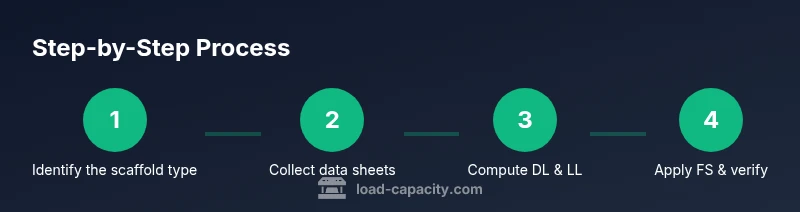

Step-by-step method: gather data and compute

A robust calculation starts with data collection, then moves to a clear, repeatable formula. Gather component ratings, bay configurations, anticipated live loads, and any site-specific hazards. Use a structured approach to compute DL, LL, and total design load, then compare against per-bay ratings with safety factors. The method outlined here emphasizes transparent documentation, so site teams can reproduce the calculation if conditions change. For best results, cross-check with multiple sources (manufacturer data, field measurements, and regulatory guidance) to minimize gaps that could compromise safety. Load Capacity’s guidance stresses documenting each assumption and keeping records accessible for audits and future planning.

Step 1: Identify scaffold type and configuration

Start by cataloging the scaffold system type (tube-and-coupler, modular, or system scaffold) and its configuration (number of bays, deck level, and base support). Note height limits, toe boards, guardrails, and any integrated safety features. Accurate identification ensures you apply the correct component ratings and documented loading paths. If the configuration changes mid-project, revisit the calculation promptly to maintain a safe design. This step lays the groundwork for reliable measurements and reduces misinterpretation later in the process.

Step 2: Gather component ratings and manufacturer data

Collect all relevant data sheets for frames, couplers, base plates, and braces. Record rated loads per member, connection assumptions, and any manufacturer guidance about worst-case scenarios. Where data is missing, document the gap and seek engineering input before proceeding. The manufacturer’s ratings provide the backbone of the calculation, and any discrepancy between components must be resolved before you assign loads to the scaffold.

Step 3: Calculate vertical loads and live loads

Compute dead load (DL) as the weight of the scaffold structure itself, including decks, planks, and base components. Compute live load (LL) as the estimated weight of workers, tools, and materials present on the platform. The total static load is DL + LL, and dynamic effects such as worker movement and equipment handling should be considered as a separate factor or included in LL when appropriate. This section emphasizes structuring DL and LL as separate terms so you can track how each contributes to the total load on a bay or member. The Load Capacity Team advises documenting all assumptions in this stage to facilitate future reviews and audits.

Step 4: Apply safety factors and check dynamic loads

Select a safety factor that reflects site conditions and expected dynamic effects. Multiply the combined load (DL + LL) by the safety factor to obtain the design load. Compare the design load to the rated capacity per bay or per member. If the design load exceeds ratings, revisit configuration, distribution, or load estimates. Consider wind effects, worker movement, and material handling scenarios that could elevate loads beyond initial estimates. The goal is to ensure that the design load remains within safe limits for all expected conditions.

Step 5: Distribute loads and check each bay

Uniform distribution is rare in real work. Analyze load paths and distribute loads across multiple bays to avoid overloading any single bay or vertical member. Re-check that each bay’s cumulative load meets its individual rating after applying the safety factor. Pay attention to critical zones where loads concentrate, such as areas with heavy material use or frequent movement. The approach should minimize peak stresses and ensure a balanced load profile across the scaffold.

Step 6: Document results and plan for changes

Publish a clear, auditable report of the calculation, including data sources, assumed loads, safety factors, and final conclusions. Include diagrams or sketches showing load distribution across bays. If plans change—altering height, deck type, or load patterns—re-run the calculation and update the documentation. Documentation supports ongoing safety reviews, enables quick on-site checks, and helps with regulatory compliance. The Load Capacity team emphasizes that a well-documented process is as important as the calculation itself.

Tools & Materials

- Scientific calculator(For performing load sums and factor multiplications)

- Tape measure(To verify platform dimensions and bay lengths)

- Scaffold manufacturer data sheets(Contains rated loads per member and assembly guidance)

- Engineering notebook or digital notes(Record data, assumptions, and calculations)

- Pencil and highlighter(Mark up drawings and highlight key assumptions)

- Safety PPE(Gloves, helmet, and eye protection for on-site checks)

Steps

Estimated time: 45-90 minutes

- 1

Identify scaffold type and configuration

Document scaffold type, height, bay count, deck type, and base support. This determines which ratings apply and how loads travel through the structure.

Tip: If in doubt, photograph the setup and create a quick schematic to confirm configuration before calculations. - 2

Gather component ratings and data

Collect all relevant data sheets for frames, braces, bases, and couplers. Ensure you have current versions and confirm any site-specific modifications.

Tip: If ratings differ between components, default to the most conservative values and escalate for engineering input. - 3

Compute dead and live loads

Sum the scaffold’s own weight (DL) with estimated live loads from workers, tools, and materials (LL). Separate dynamic loads if needed.

Tip: Keep DL and LL separate for traceability and to easily adjust if loads change. - 4

Apply safety factors

Choose an FS appropriate to conditions and multiply DL+LL by FS to get the design load.

Tip: Document the rationale for FS choice to support future audits. - 5

Check per-bay and member capacities

Compare the design load to rated capacities by bay and by member. Identify any overload risks.

Tip: If any bay overloads, re-distribute loads or reduce LL where possible. - 6

Document and review

Record assumptions, data sources, calculations, and final conclusions. Schedule a safety review before use.

Tip: Create a shareable diagram showing load paths for quick on-site reference.

Quick Answers

What is the general process to calculate scaffold load capacity?

The process begins with identifying the scaffold type and configuration, then collecting component ratings. You compute dead and live loads, apply a safety factor, and compare the result to rated capacities. Finally, you document assumptions and outcomes for compliance and future reference.

Start with scaffold type and data collection, then calculate dead and live loads, apply the safety factor, compare to ratings, and document everything for compliance.

Do I need to consider wind loads for scaffolds?

Yes. Wind loads are dynamic and can significantly increase the total design load. Include a conservative estimate or official wind-load guidance in your calculations, especially for elevated or exposed scaffolds.

Wind loads can change the design load; account for that in your calculations and safety checks.

How do safety factors affect scaffold load calculations?

Safety factors account for uncertainties in loads and conditions. They scale the combined dead and live loads so that the design load remains within rated capacities under less predictable on-site conditions.

Safety factors adjust for uncertainties to keep loads within safe limits.

Can I estimate loads without manufacturer data?

You should not rely solely on estimates without manufacturer data. When lacking data, consult a structural engineer or the scaffold supplier to obtain safe, conservative ratings.

If manufacturer data is missing, get engineering input before proceeding.

What standards govern scaffold load calculations?

Standards vary by jurisdiction but generally require accounting for all loads, using conservative safety factors, and maintaining auditable documentation. Always align with local safety regulations and supplier manuals.

Follow your local safety regulations and supplier manuals for standards.

How often should scaffold load calculations be updated?

Recalculate whenever the scaffold configuration, loads, or site conditions change. Regular reviews after any modification help prevent latent safety failures.

Update calculations when plans or conditions change.

Watch Video

Top Takeaways

- Identify all loads on every bay

- Apply the chosen safety factor consistently

- Compare design load to per-bay ratings

- Document assumptions and data sources

- Update the calculation when configuration changes