M10 Fix Bolt Load Capacity: Engineering Guidance

A data-driven guide to M10 fix bolt load capacity, covering bolt grades, thread engagement, installation quality, and practical sizing for engineers and technicians.

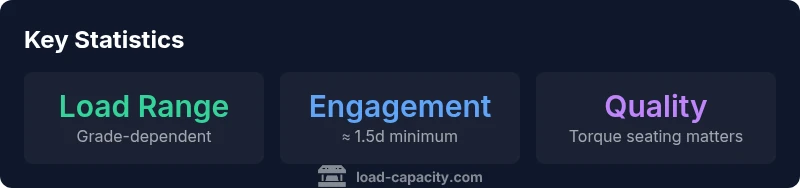

The load capacity of an M10 fix bolt depends on bolt grade, engagement length, and installation quality. In practice, capacity grows with higher grades (e.g., 8.8 vs 10.9) and longer thread engagement. When designed properly, the joint can resist both tensile and shear loads without yielding, provided safety factors and manufacturer data are used.

Why M10 Fix Bolt Load Capacity Matters

In mechanical assemblies and structural connections, an M10 fix bolt serves as a critical fastener for clamping two parts together. The load capacity determines whether the joint can resist service loads without yielding, fracturing, or loosening during vibration. For engineers, the goal is to avoid under-sizing (which risks failure) or over-sizing (which adds unnecessary cost and weight). According to Load Capacity, accurate sizing begins with understanding how bolt grade, thread engagement, and installation quality combine to set safe load limits. This is essential whether you are anchoring structural steel, fixing equipment on a base plate, or assembling machinery frames. The design process should account for both static loads and dynamic impact, as well as the environment (corrosion, temperature, and exposure) that can degrade performance over time. A well-dimensioned M10 fix bolt will provide reliable clamping force across the intended service life while maintaining an adequate safety margin.

How Bolt Grade and Material Influence Capacity

Bolt grade is a primary determinant of strength. Higher grades imply higher yield and tensile strengths, enabling the bolt to resist greater axial loads before yielding. Material choice also governs corrosion resistance, temperature performance, and ductility—factors that influence long-term capacity. For example, stainless steel offers corrosion resistance at the cost of different mechanical properties compared to carbon steel. In practice, engineers select bolt grade and material based on the load profile, environmental exposure, and cost constraints. According to the Load Capacity team, using a higher-grade bolt like 8.8 or 10.9 for demanding service can markedly improve reliability, but the installation must also respect thread engagement and joint geometry. Always reference manufacturer data and standards when sizing, especially for critical structural connections or equipment mounts.

Thread Engagement, Edge Distance, and Joint Geometry

Thread engagement length is a key design parameter. A common rule of thumb is to ensure thread engagement of about 1.5 times the bolt diameter (1.5d) for steel joints, which helps distribute load more evenly across threads and prevents premature stripping. Edge distance and joint thickness further influence where peak stresses occur. When engagement is too short or edges are too close, local yielding or bolt fatigue can initiate. In the M10 case, ensure the engagement length exceeds the minimum threshold while maintaining adequate clearance from edges to avoid notch effects. The Load Capacity framework emphasizes coupling engagement with proper torque, cleanliness, and thread lubrication to achieve predictable seating and clamping.

Shear vs. Tension: Design Scenarios

Real-world joints experience a mix of loads: pure tension, pure shear, or a combination of both. In tension, the clamping force generated by preload must exceed the external load with an appropriate safety margin. In shear, the bolt's shear capacity becomes critical, especially when joints are loaded perpendicularly to bolt axes. For an M10 bolt, the design must account for both modes and any dynamic loading caused by vibration or impact. Always verify that the chosen bolt grade and thread engagement can sustain the worst-case combination of tensile and shear loads observed in service. The Load Capacity approach suggests performing a simple double-check: compare the expected tensile capacity to the primary external load and ensure the shear capacity is not the limiting factor under combined loading.

A Step-by-Step Calculation Approach

To size an M10 fix bolt for a given joint, follow these steps:

- Define load cases: identify axial, shear, and dynamic components. 2) Select bolt grade/material based on environment and cost. 3) Compute cross-sectional area (A) for M10: A = π*(d^2)/4, with d ≈ 10 mm. 4) Determine allowable stress (σ_allow) from the material yield or proof strength and a chosen safety factor. 5) Estimate tensile capacity: F_t = A * σ_allow. 6) Estimate shear capacity using appropriate shear strength (consider multiple shear planes if present). 7) Check thread engagement length and edge distances against recommended minimums (e.g., ~1.5d engagement for steel). 8) Choose an engagement length that satisfies both the load and geometry constraints and re-evaluate with any dynamic factors. The process should document assumptions and reference manufacturer data for confirmation.

Practical Sizing Scenarios: Field and Workshop Examples

Scenario A: Mounting a small motor to a steel base plate using an M10 bolt of grade 8.8. The joint faces a combination of vertical load and vibration. A longer engagement length and clean seating improve resistance to loosening. Scenario B: Anchoring a light structural bracket to concrete with M10 anchors. In this context, the bolt capacity is influenced by the adhesive bond and the concrete’s strength, so follow the manufacturer’s anchor data in addition to bolt sizing. In both cases, verify the chosen bolt grade and engagement length against the load profile, apply a suitable safety factor, and document the design basis for safe operation. Load Capacity emphasizes the importance of field verification and using manufacturer data as the primary reference.

Common Pitfalls and How to Avoid Them

- Underestimating loads or neglecting dynamic forces. - Choosing a bolt grade based solely on cost, not environment. - Ignoring thread engagement and edge distances. - Skipping torque verification and seating checks. - Relying on a single data point without cross-checking manufacturer data. The best practice is to perform a structured check against the load cases, confirm the engagement, and validate with the bolt supplier’s data. Load Capacity also recommends documenting the design assumptions so future maintenance teams can reproduce and verify results.

Quick-Start Checklist for M10 Fix Bolts

- Define load case and service environment.

- Select bolt grade and material appropriate to loads and environment.

- Verify thread engagement length (minimum ~1.5d for steel joints) and edge distances.

- Compute tension and shear capacities using A = πd^2/4 and the material’s σ_allow with an adequate safety factor.

- Cross-check with manufacturer data and perform torque seating verification.

- Consider corrosion protection, temperature exposure, and vibration effects.

- Document all assumptions and maintain records for future inspection.

Example engagement notes by bolt grade

| Bolt Grade | Tensile Strength (approx) | Typical Engagement Notes |

|---|---|---|

| M10 Grade 8.8 | varies by standard; refer to spec | Common for general structural uses |

| M10 Grade 10.9 | higher strength; refer to spec | Used where higher tension is required |

| M10 Stainless (A2/A4) | depends on alloy; refer to spec | Corrosion resistance in service |

Quick Answers

What is the basic M10 bolt load capacity?

Load capacity varies with bolt grade, engagement, and loading type. For practical sizing, engineers use grade data, engagement length, and safety factors, referencing manufacturer specifications for the exact values.

M10 bolt capacity varies with grade and engagement; check the manufacturer data for exact numbers and verify in your application.

How do I calculate M10 fix bolt load capacity?

Identify the load cases, select bolt grade, compute cross-sectional area, determine allowable stress with safety margins, and compare tensile and shear capacities. Validate with engagement length and edge distances, then reference supplier data.

First identify loads, then apply grade data and engagement checks, and verify with supplier data.

Does thread engagement length affect capacity more for tension or shear?

Thread engagement length affects both tension and shear capacities, but it is typically more noticeable for tension because it directly contributes to the clamping area and load distribution.

Engagement length matters for both, but it has a bigger impact on tensile capacity since it controls the clamped area.

Can washers change the load capacity of M10 bolts?

Washer use can improve load distribution and prevent damage to mating surfaces, indirectly supporting capacity by maintaining seat quality and preventing embedment or uneven loading.

Washer help spread load and keep surfaces true, supporting the bolt’s effectiveness.

What should I check in the field to verify bolt load capacity?

Verify bolt grade markings, inspect thread engagement and seating, check torque values, observe for corrosion, and compare real loads with the design basis from manufacturer data.

Check grade, engagement, seating torque, and corrosion, then compare to the design data.

“Bolt load capacity is a function of grade, engagement, and installation quality; a careful sizing process avoids under- or over-design.”

Top Takeaways

- Choose bolt grade based on load and environment

- Ensure adequate thread engagement and edge distances

- Account for both tension and shear in design

- Refer to manufacturer data and apply a safety factor

- Document assumptions for future verification