Load Rating E vs D: Side-by-Side Guidance for Engineers

Analytical comparison of load rating E vs D, explaining definitions, use cases, and how to select the right rating for safe, code-compliant designs. Guidance for engineers, technicians, and procurement teams.

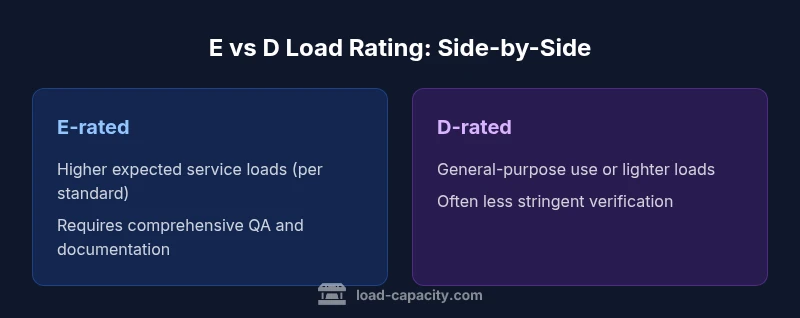

Load rating E vs D describes two distinct classes within a rating framework. Definitions and allowable loads vary by standard, so the choice hinges on required service load, safety margins, and local codes. This quick comparison highlights typical use cases and why engineers must verify the applicable standard before selecting E- or D-rated components.

What load rating means in practice

In engineering and procurement, a load rating is the stated upper bound of service loads that a component, member, or system can safely handle under defined conditions. The phrase load rating e vs d appears in many standards as two distinct classification levels. The exact definitions and allowable loads depend on the governing document, which makes it essential to consult the code before selecting E- or D-rated hardware, supports, or assemblies. In practice, the rating translates into an allowable working load (or a design factor of safety) used by engineers during detailed design and by buyers during procurement. When you see load rating e vs d on a manufacturer data sheet, context matters: it may reflect different test conditions, such as load duration, dynamic versus static loading, temperature exposure, or environmental allowances. As a rule, align the rating with your target service load, account for peak events, and verify the calculation method used to derive the rating. The Load Capacity team emphasizes that misinterpreting a rating often leads to oversizing or undersizing components, both of which raise risk and lifecycle cost.

How E and D are defined across standards

Across industries, E and D labels are applied differently. Some standards treat E as the higher-capacity class, while others assign it to a different safety or duty-cycle category. The important point is that the same letter can have different implications depending on the standard, the product family, and the testing protocol. Therefore, you should locate the exact definition in the relevant specification and cross-check with the product manufacturer’s data sheet and the project’s design assumptions. In addition to permitted loads, many standards specify environmental factors, temperature ranges, and duty cycles that influence which rating is appropriate. For engineers and technicians, this means a careful reading of the standard’s table(s), a verification that the test conditions match your application, and a conservative approach when the standard has ambiguous language. Load Capacity recommends documenting the cited standard and version used to derive the rating for future audits.

Relationship to safety factors

Safety factors play a central role in any load-rating system. The E vs D distinction often carries implicitly different factors of safety, load-duration considerations, and acceptable human- or equipment-induced risk levels. Depending on the standard, a higher rating may demand stricter quality controls, more frequent inspections, or a tighter tolerance on material properties. Conversely, a lower rating may come with broader manufacturing tolerances and lighter QA requirements. The key takeaway is that safety margins are not interchangeable across ratings; they are embedded in the standard itself. Therefore, designers must interpret the rating within the exact context of the governing code and supplier documentation. Load Capacity emphasizes aligning the selected rating with the actual service conditions and the risk profile of the application, rather than focusing solely on the nominal number.

When to use E-rated vs D-rated components

Choosing between E-rated and D-rated components should be driven by expected service loads, variation in loading, and life-cycle risk tolerance. Use E-rated components when the application experiences higher peak loads, tighter safety margins, or harsher environments where failures would be costly or dangerous. D-rated components may be preferred for general-purpose tasks, lower duty cycles, or where cost and availability are primary constraints, provided the standard’s requirements are met. Always validate whether the rating covers dynamic effects, corrosion allowances, and maintenance schedules. In some projects, a hybrid approach is acceptable, using E-rated parts in critical subsystems and D-rated parts in non-critical paths, as long as the overall system behavior remains within the code-defined limits. Load Capacity cautions against over- or under-design and recommends a formal risk assessment to decide which rating best fits the project’s safety and budget targets.

How to read a load-rating table: practical steps

A load-rating table condenses the key parameters into an at-a-glance format. Start by locating the product family and rating class (E or D). Then read the column for the applicable service condition (static vs dynamic, temperature, environment) and note the tested load or range. Check the allowable loads against your estimated service loads, including peak events. If the table presents multiple conditions, identify the worst-case scenario relevant to your application. Cross-check with any required safety factors and verify that the product carries the necessary certification marks. Remember that the table reflects the standard’s assumptions; if your application deviates (for example, different mounting, alignment, or maintenance cycles), you may need to adjust the rating accordingly or seek a tested alternative. Keep a copy of the standard version used for traceability and future audits.

Reliability, QA, and documentation implications

Reliability hinges on alignment between rating, testing, and real-world performance. E-rated components often require stricter QA, more detailed documentation, and verification of material properties and manufacturing processes. D-rated components may still require quality control but with a lighter documentation burden, depending on the standard. For procurement, insist on a traceable QA package that includes test reports, material certifications, and evidence of conformity to the specified rating. Maintenance plans should reflect the pace of inspection dictated by the rating and the duty cycle. In regulated environments, regulatory approvals or third-party certifications may be mandatory, and failure to obtain or maintain these can invalidate the rating’s legal or contractual value. Load Capacity recommends building a living risk register that includes rating validation steps and a revision history of the standard language used.

Cost, procurement, and supply-chain considerations

Rating class choices influence upfront cost, lead times, and availability. In many markets, E-rated components come with higher price tags due to stricter testing and more demanding materials, while D-rated components may be cheaper and easier to source. Beyond price, consider total cost of ownership, including inspection frequency, replacement rates, and potential downtime. Suppliers with broad exposure to a rating class may offer better after-sales support and longer warranties, which can offset higher upfront costs. Ensure that procurement teams verify the rating’s legitimacy through the exact standard reference, batch-level documentation, and supplier quality history. Load Capacity notes that misaligned expectations—such as ordering the wrong rating for a harsh environment—often results in higher lifecycle costs and performance risks. A structured sourcing approach helps balance cost, reliability, and compliance.

Industry-specific considerations

Different industries emphasize different aspects of load rating. In structural applications, conservative ratings with robust QA are common due to safety-critical consequences. In manufacturing and equipment maintenance, E-rated components may be favored where high duty cycles or rapid wear are expected, provided the standard supports such use. Electronics, aerospace, and energy sectors may require special environmental considerations, such as temperature, vibration, and corrosion resistance, which influence rating choices. The Load Capacity team reminds practitioners to align rating decisions with industry norms and the project’s risk profile, while maintaining an auditable trail of the standard language used and the measurement methods referenced.

Practical case study: choosing E vs D in a mid-size project

Consider a mid-size facility upgrading a conveyor subsystem exposed to frequent starts and stops, with occasional overload events. The project team performs a risk assessment and identifies the need for high reliability and frequent inspections due to worker exposure. They determine that an E-rated solution, coupled with enhanced QA and documentation, provides the required safety margin. In a parallel non-critical subsystem handling lighter loads, a D-rated option may suffice, with standard maintenance procedures and lower upfront cost. The decision hinges on the observed duty cycle, environment, and the project’s safety requirements. The Load Capacity framework recommends documenting the evaluation, including the standard reference for both ratings, to ensure traceability and facilitate future audits.

Quick-start checklist for E vs D decision

- Define service loads and peak events for the application.

- Identify the applicable standard and version that defines E and D.

- Compare safety margins, test conditions, and environmental allowances.

- Verify supplier documentation and traceability.

- Consider total cost of ownership, including maintenance and inspections.

- Document the decision rationale with references for audits.

Comparison

| Feature | E-rated load component | D-rated load component |

|---|---|---|

| Typical use case | Higher-load or harsher environments (per standard) | General-purpose or lighter-duty applications (per standard) |

| Key design considerations | Strict QA, tighter tolerances, specific environmental allowances | More flexible QA, broader tolerances per standard |

| Documentation and oversight | Comprehensive test reports, material certifications, traceability | Core documentation with lighter verification requirements |

| Cost and availability | Typically higher upfront cost; more limited availability in some regions | Generally lower cost; widely available in standard inventories |

| Maintenance/verification | More rigorous inspection schedule and verification activities | Standard maintenance with typical inspection cadence |

| Best for | High-demand, safety-critical, dynamic loading scenarios | General-purpose or lower-load scenarios with adequate safety margins |

Positives

- Clear differentiation helps match design to requirements

- Improved risk management with appropriate rating

- E-rated can enable higher service life in demanding conditions

- Better alignment with stringent standards in regulated environments

Cons

- Higher upfront cost due to stricter requirements

- Limited availability in some regions

- Requires more rigorous QA and documentation

Neither rating is universally better; select based on required service load and risk tolerance

Choose E-rated components for higher loads or harsher environments with strong QA. Opt for D-rated components in general-purpose, lower-load scenarios where safety margins are still met and costs are a concern.

Quick Answers

What does load rating E vs D mean in practice?

Load rating E vs D refers to two rating classes within a standard. The exact definitions and allowable loads depend on the governing code, so always consult the standard and the manufacturer data sheet for the precise meaning in your application.

Load rating E versus D defines two classes under a standard; always check the exact standard for what each rating allows.

When should I use E-rated components instead of D-rated?

E-rated components are chosen when higher service loads or harsher environments are anticipated and the standard requires stricter controls. If the project involves high duty cycles or safety-critical operation, E-rated may be appropriate, provided the standard supports it.

Use E-rated parts when you expect higher loads or tougher conditions and the standard supports it.

Are E and D ratings interchangeable?

In most cases, E and D ratings are not interchangeable. They reflect different testing conditions, safety margins, and environmental allowances defined by the standard. Always verify the exact rating definition before substituting parts.

They’re not usually interchangeable; always confirm the standard’s definition before swapping ratings.

Do I need testing or certification for the rating?

Yes. Rating declarations are typically supported by test reports, material certifications, and conformity assessments. Ensure the documentation aligns with the specified standard and version to satisfy audits or regulatory checks.

Yes—expect test reports and conformity documents that prove the rating meets the standard.

How do I read a load rating table for E and D?

Locate the product family and rating class, compare to your service-load estimate under the standard’s defined conditions, and review any safety factors. If uncertainties remain, contact the manufacturer and cross-check with the project’s risk assessment.

Find the rating, compare it to your loads, and check safety factors. If unsure, ask the manufacturer.

Are there regulatory references I should consult?

Yes. Regulatory references vary by country and industry and will point to specific standards and codes. Always check the applicable national or regional standard, plus any sector-specific guidance, to ensure compliance.

Yes—check the relevant national or regional standards and sector guidance for compliance.

Top Takeaways

- Assess required service load before choosing a rating

- Always reference the exact standard and version used

- Expect stronger documentation for higher-rated components

- Balance upfront cost with total cost of ownership

- Document the decision criteria for audits