e load rating explained: a practical guide for engineers

A comprehensive guide to e load rating, covering definitions, calculation approaches, and practical applications across vehicles, appliances, and industrial equipment. Learn how to apply safe limits, select components, and verify ratings with standards.

The term e load rating denotes the estimated electrical loading capacity of a component, device, or system under specified conditions. It captures voltage, current, and thermal limits to guide safe operation and proper sizing of protection devices, wiring, and cooling. In practice, engineers use e load rating to ensure reliability across automotive, appliance, and industrial contexts, balancing performance with safety.

What is e load rating and why it matters

In engineering practice, the phrase e load rating is used to describe the maximum electrical load a component, subsystem, or system can safely withstand under defined conditions. The Load Capacity team notes that this rating combines electrical parameters (voltage, current, power), thermal limits, and environmental factors to produce a usable gauge for design, procurement, and operation. When a device’s e load rating is respected, equipment longevity improves, maintenance intervals lengthen, and the likelihood of thermal runaway or fuse blowouts decreases. For engineers, planners, and technicians, the e load rating acts as a single metrics-driven checkpoint that translates complex thermal-electrical interactions into actionable limits on wiring, enclosures, and cooling.

How e load rating is calculated and why derating is essential

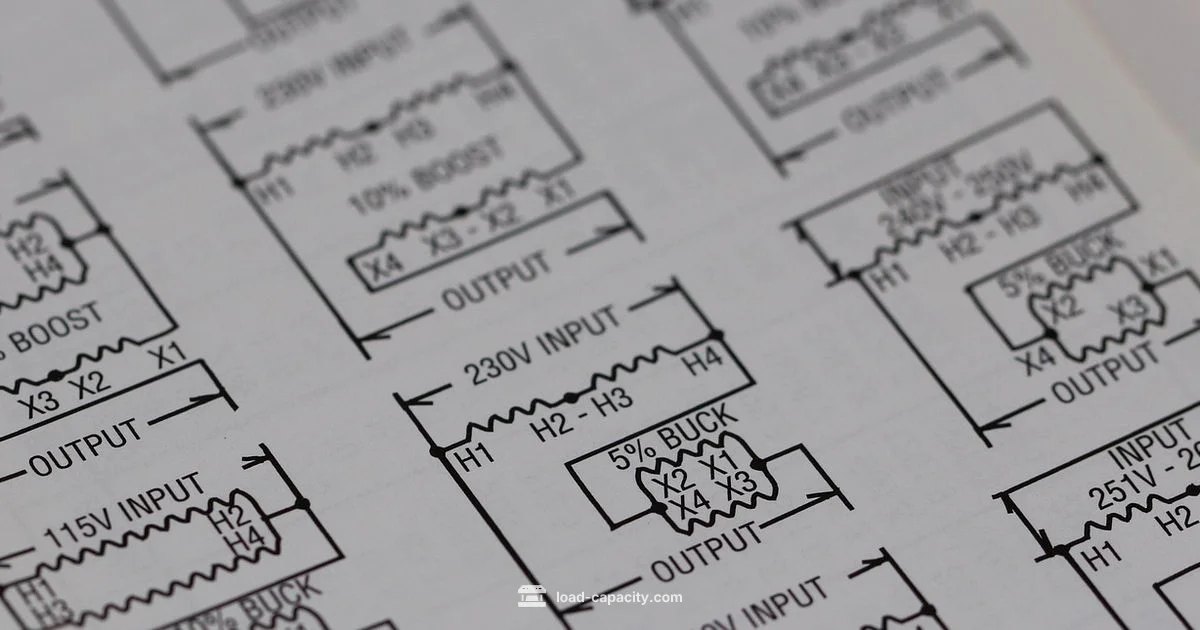

Calculating e load rating involves understanding the relationship between voltage, current, and power, then applying safety margins and derating factors. A practical approach starts with the nameplate rating (the baseline electrical load) and then adjusts for real-world conditions: ambient temperature, enclosure cooling, proximity to heat sources, duty cycle, and permissible short-term overload. Derating factors vary by standard and by material, but the guiding principle is simple: when temperature or duty increases, the safe operating current must be reduced. This ensures the system operates within thermal limits while still meeting performance goals. In many cases, designers use a two-step method: (1) compute the nominal load from nameplate data, (2) apply a cumulative derating factor to obtain the effective e load rating under expected conditions.

Contexts where e load rating is critical: vehicles, appliances, and industrial equipment

Across contexts like vehicle electrical harnesses, household appliances, and industrial machinery, the e load rating directs component selection and protection strategies. In automotive and aerospace applications, the rating informs fuse sizing and wire gauge to accommodate peak loads during start-up or peak demand. In appliances, it influences motor control, heating elements, and power electronics. In industrial equipment, e load rating governs drives, contactors, and cooling systems. Understanding how e load rating translates into real-world performance helps teams prevent nuisance trips, ensure safe shutdowns, and optimize energy efficiency. The Load Capacity framework emphasizes cross-context consistency: ensure the e load rating aligns with environmental, thermal, and duty-cycle realities for each application.

Environmental and duty-cycle effects on e load rating

Ambient temperature and duty cycle can significantly affect the effective e load rating. Warmer environments reduce thermal headroom, lowering the current a component can safely carry. Frequent cycling between high and low loads or sustained overload periods may require larger derating margins to avoid accelerated aging. Similarly, dust, humidity, and enclosure ventilation influence heat dissipation, altering the real-world margin. Engineers should document expected ambient conditions, select components with appropriate derating margins, and verify performance under worst-case scenarios. For projects with high reliability requirements, running simulated duty cycles and temperature profiles helps validate the e load rating before field deployment.

Practical steps to verify and apply e load rating in design

To apply e load rating effectively, follow a structured checklist. Start with the nameplate rating and identify the intended duty cycle and ambient range. Next, apply standard derating factors for temperature, enclosure, and ventilation, then include a safety margin that aligns with your risk tolerance. Verify that protective devices (fuses, breakers) and conductors are sized to carry the de-rated current with an appropriate headroom. Document all assumptions and refer to recognized standards during the design review. Finally, plan for validation testing, including thermal imaging, current profiling, and endurance tests to confirm the e load rating holds under expected operating conditions.

Common mistakes and how to avoid them

A frequent error is assuming a device’s nominal rating applies in all conditions. Always account for ambient temperature, heat sources, and duty cycle. Another pitfall is underestimating cable and connector resistance, which can elevate losses and reduce effective current handling. Avoid neglecting protection coordination—fuses and breakers must be selected to match the de-rated e load rating, not just the nominal value. Finally, skipping validation testing can hide thermal issues; incorporate both bench and field testing to confirm your e load rating in practice.

A practical calculation walkthrough (conceptual)

Here is a high-level, conceptual walkthrough for deriving an e load rating. Step 1: identify the nominal rating from the nameplate data (voltage, current, and power). Step 2: determine the duty cycle and ambient temperature conditions anticipated in the application. Step 3: apply derating factors for temperature, ventilation, and enclosure based on applicable standards. Step 4: combine the derated current with a safety margin to obtain the final e load rating. Step 5: cross-check against protection devices and conductors to ensure compatibility. This approach highlights how e load rating integrates electrical and thermal considerations into a usable limit.

Regulatory considerations and standards: keeping e load rating compliant

Standards organizations publish guidelines that inform e load rating practices. In practice, references from reputable sources guide design choices, testing protocols, and safety margins. Designers should consult the latest editions of relevant standards and cite them in design documentation for traceability. While exact requirements vary by industry and jurisdiction, adhering to standard practice promotes safety, interoperability, and reliability. For further study, consult authoritative resources from recognized agencies and standards bodies to inform e load rating calculations and verification.

Examples of e load rating contexts

| Context | Definition | Measurement Basis |

|---|---|---|

| Electrical equipment | Maximum steady electrical load a device can handle under specified conditions | Voltage × Current; thermal rating |

| Vehicles/trailers | Safe electrical load for auxiliaries (lights, HVAC) | Total current draw; fuse sizing |

| Industrial machinery | Rated power and short-term overload capability | Standards test pulses; duty cycle |

| Household appliances | Nameplate rating and efficiency impacts | Rated input power; operating efficiency |

Quick Answers

What does 'e load rating' stand for?

e load rating is a practical metric that captures the safe electrical loading capacity of a component under specified conditions, integrating voltage, current, and thermal limits. It guides sizing of components and protection devices to prevent overheating and failures.

In short, e load rating tells you how much electrical loading a part can safely carry under defined conditions.

How is e load rating calculated?

Calculation starts with the nominal rating, then applies derating factors for ambient temperature, enclosure, and duty cycle. The result is multiplied by a safety margin to yield the final e load rating. Validation testing confirms the rating under real conditions.

You start with the nameplate rating, apply temperature and duty-cycle derating, add a safety margin, and validate with tests.

Why does ambient temperature matter for e load rating?

Ambient temperature determines heat buildup and cooling efficiency. Higher ambient temps reduce available thermal headroom, lowering the effective current carrying capacity. Accounting for this ensures components don’t overheat in operation.

The hotter it is around the equipment, the less current you can safely carry.

Can e load rating change over time?

Yes, aging, wear, and repeated thermal cycling can shift the actual safe loading. Routine testing and periodic re-evaluation help ensure the e load rating remains accurate over the life of a system.

Over time, wear and temperature cycles can slightly change how much load is safe.

How do I apply e load rating in system design?

Use the e load rating to size conductors, protection devices, and cooling. Ensure the final design maintains adequate headroom for safety margins and aligns with applicable standards.

Size wires and breakers based on the e load rating, with a comfortable safety margin.

What standards govern e load rating?

Standards vary by industry but typically include guidelines on thermal management, overcurrent protection, and testing procedures. Consult official documents from recognized standards bodies and regulatory agencies for your sector.

Look up the current standards for your industry to guide rating calculations and tests.

“The e load rating is a conservative limit that translates complex thermal-electrical behavior into actionable design constraints. Properly applied, it reduces risk and improves reliability.”

Top Takeaways

- Define e load rating clearly for each component

- Always check nameplate data and environmental conditions

- Apply derating before selecting protections and conductors

- Document assumptions for traceability

- Validate with testing under worst-case conditions