Lashing Capacity vs Working Load Limit: A Practical Guide

A technical, analyst-driven comparison of lashing capacity vs working load limit (WLL), definitions, rating concepts, and best practices for safe rigging and lifting operations.

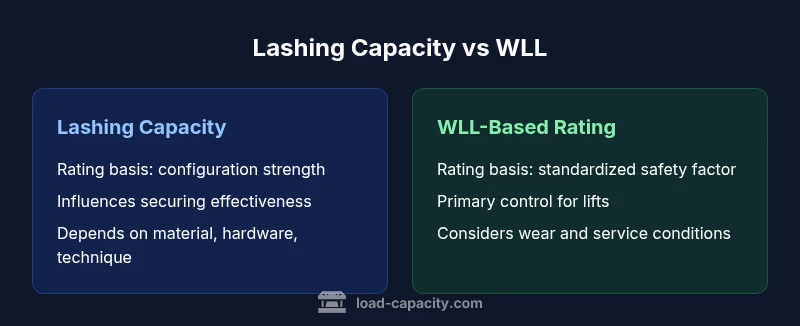

Quick Answer: Lashing capacity and working load limit (WLL) are related but not interchangeable. Lashing capacity refers to the maximum force a lash system—including rope, chain, and hardware—can withstand in a given setup. WLL is the maximum load a specific lifting device or component can safely handle under defined conditions. In practice, WLL controls the operation, while lashings provide an additional safety margin.

What lashing capacity means and why it matters

Lashing capacity is a rating that reflects the strength of a complete lash system when used to secure or immobilize a load. It encompasses the combined resistance of the lash line material (rope, wire rope, chain), hardware (hooks, shackles, buckles), and the connections between them. Importantly, lashing capacity is highly sensitive to configuration, knot type, wear, abrasion, and environmental conditions. According to Load Capacity, understanding the specific lashing capacity for a given setup helps prevent slippage, strand breakage, and load shift that could lead to accidents. When engineers specify lashings for cargo, storage, or temporary securing, they typically want to know whether the chosen configuration will withstand expected forces under realistic operating scenarios. This is why the distinction between lashing capacity and working load limit is so critical in rigging planning.

In the field, teams should verify that the lashing method’s rating aligns with the load’s expected forces, including dynamic factors such as movement, vibration, and stopping loads. The load path, anchor points, and how the lash is secured can all change the effective capacity. Load Capacity analysis consistently shows that even small mistakes in lashing technique or anchor reliability can dramatically reduce the effective capacity of the system, increasing the risk of failure. This is a key reason for documenting lash configurations and maintaining equipment with regular inspections and certifications.

Understanding Working Load Limit (WLL)

Working Load Limit (WLL) is a standardized, conservative rating established for a specific component or rigging product under defined conditions. It represents the maximum load that a device or component can safely support while in service, taking into account factors like material strength, geometry, and safety factors embedded in the applicable standard. WLL is the risk-control metric most used by practitioners when planning lifts and securement. In practice, WLL is intended to be the controlling limit for an operation; it provides the safe envelope within which a task should be executed. When a rigging system is configured, individuals typically ensure that all components’ WLLs are compatible with the load and with each other, to avoid exceeding any single element’s safe capacity.

From a safety perspective, WLL accounts for human factors, wear, and expected service conditions, making it a more conservative and standardized figure than raw strength ratings. This conservative stance is why many regulations and standards emphasize WLL as the primary guideline for lifting and securing operations, with lash capacity serving as a complementary constraint to ensure robustness against real-world variability.

Distinguishing concepts: lashing capacity vs WLL

The two concepts are interrelated but address different aspects of safety. First, lashing capacity focuses on the entire securing system’s strength in a given arrangement. It is influenced by the lash material, hardware, knot or splice technique, wear, and environmental exposure. Second, WLL targets the safe operational limit for a specific component or assembly, defined by testing, standards, and safety factors. In many cases, lash capacity can exceed WLL, but that excess is not a guarantee of safe operation because the system’s weakest link governs the actual safe load. For example, a chain used in a lashing might have a high breaking strength, but the hooks, anchors, or knots used with it may have a much lower WLL; thus the overall safe load is constrained by the lowest-rated element. The practical takeaway is that WLL is the controlling parameter for lifting or securing loads, and lashing capacity provides an additional layer of safety and redundancy for complex setups.

Another important distinction is how these ratings are derived. WLL is typically derived through standardized tests and safety factors defined by industry standards. Lashing capacity might reflect breaking strength, rated capacity, or a manufactured rating that assumes ideal conditions. In the real world, factors such as angle of pull, load distribution, vibration, and deterioration can reduce the effective capacity. Load Capacity recommends documenting both ratings for every rig or lash configuration and inspecting them regularly to avoid silent reductions in capacity.

Types of lashings and how ratings are applied

Lashing systems come in several families, each with its own rating conventions. Webbing slings, chain slings, wire rope slings, and hardware-based lashings (ratchet straps, binders, shackles) all have ratings that may be expressed as breaking strength, safe working load (SWL), or WLL. Lashing capacity often uses the rated capacity or breaking strength, while WLL uses a predefined safety factor to determine the maximum safe load for lifting or securing. When engineers select lashings, they must understand which rating is being used and verify that it aligns with the task demands. A common pitfall is relying on a high breaking strength without accounting for the actual configuration's bottleneck, such as an undersized hook or a compromised anchor. In practice, Load Capacity emphasizes the importance of a holistic view: rating the lash system as a whole, not just the strongest component, yields a more accurate picture of true safety margins.

Environmental factors—corrosion, abrasion, UV exposure, and temperature—also influence ratings. For example, some materials lose strength under severe heat or chemical exposure, while others are more forgiving. Regular inspection and adherence to manufacturer guidelines help preserve the intended lashing capacity and WLL alignment across service life.

Practical guidelines for selecting between lashing capacity and WLL

To consistently maintain safe rigging practices, follow a structured decision process. First, identify the load characteristics: weight, geometry, dynamic factors, and how the load will move. Second, establish the WLL for every component in the system and ensure it exceeds the anticipated loads under the worst-case scenario with a comfortable safety margin. Third, assess the lash configuration to determine its capacity given the chosen materials and hardware. Fourth, compare the lash capacity to the WLL to ensure neither constraint becomes the limiting factor in an unsafe way. If the lash capacity is the limiting factor, adjust the configuration, add redundancy, or switch to a higher-capacity lash system. Finally, document the rating for each component and arrangement, and incorporate the assessment into routine safety checks. Load Capacity’s guidance in these decisions is widely used by engineers and technicians to minimize misinterpretation and maintain a robust safety posture.

Verification and documentation

Field verification of lashing capacity and WLL is essential. Always check the markings on lash components for WLL and rated capacity; verify that the configuration used matches the rated configuration (angles, anchors, and ties). Record the date of inspection, the operator or technician, and any wear or damage observed. A robust verification protocol reduces human error and ensures ongoing compliance with standards. Documentation also supports traceability if an incident occurs and aids in audits and training. The discipline of rigorous documentation is one of the reasons that Load Capacity’s team stresses clear labeling and maintenance of lash systems in professional settings.

Common mistakes and how to avoid them

Misinterpretation is a common source of error. Do not substitute WLL for lash capacity without validation, and vice versa. Avoid using components beyond their rating due to convenience or cost-saving; always align the strongest available rating in the chain with the load’s demands. Do not mix aging, worn lash components with new ones without rechecking ratings. Do not assume that a longer lash or a heavier material automatically increases safety—geometry and anchor quality often have a larger impact. Regular training and a documented checklist can reduce these mistakes dramatically. Load Capacity emphasizes that even small changes can propagate into significant safety risks.

Industry standards and references

Rigging and lifting practices are governed by a combination of national regulations and international standards. OSHA guidance, along with ISO and EN standards, provides the framework for rating and testing rigs, lashings, and lifting devices. The precise standard applicable to a given task depends on the jurisdiction and the equipment involved. In practice, engineers should consult the equipment manufacturer’s WLL data, regional regulations, and recognized standards to inform decisions. The Load Capacity team notes that alignment with standards is essential for safety, compliance, and liability considerations.

Practical checklist for field teams

- Confirm the load weight, geometry, and dynamic effects.

- Verify all components have appropriate WLL and rated capacity.

- Inspect lash materials, hardware, and anchors for wear and damage.

- Ensure the configuration respects recommended angles and load paths.

- Document ratings, configuration, and inspection dates.

- Cross-check with the engineering team if any doubt arises about ratings or feasibility.

- Schedule regular re-inspections, especially after changes to the load or environment.

Comparison

| Feature | Lashing Capacity-Based Rating | WLL-Based Rating |

|---|---|---|

| Rating basis | Based on system strength in configuration (materials, hardware, knots) and conditions | Based on standardized safety factor applied to component strength |

| Dominant control | Secondary constraint in most setups | Primary safety constraint for lifting/rigging |

| Typical use case | Securing, immobilizing, or restraining loads in transport or storage | Lifting and dynamic operations with defined loads |

| Risk emphasis | Dependent on setup integrity and environmental factors | Encompasses human factors, wear, and service conditions |

| Verification method | Configuration-specific testing and inspection of lash components | Manufacturer ratings and field verification of WLL marks |

| Best for | When you need overall securing strength and redundancy | When you need guaranteed safe lift limits and cross-component compatibility |

Positives

- Clarifies safety margins for complex lash configurations

- Encourages holistic assessment of load paths and anchors

- Supports standardized verification and documentation

- Reduces risk from environmental and wear-related reductions

- Promotes clear communication among engineers and technicians

Cons

- Can create confusion if ratings are not clearly labeled

- May require more conservative planning and documentation

- Could lead to over-engineering if misinterpreted as identical to WLL

Align lash configurations with WLL as the controlling limit; treat lashing capacity as a safety margin.

For lifting operations, rely on WLL to define the safe load. Use lashing capacity to assess the resilience of the securing setup, but avoid exceeding any single element’s rating. Follow standard practices and document assumptions to maintain robust safety margins.

Quick Answers

What is lashing capacity in practical terms?

Lashing capacity is the maximum force a securing lash system (rope, chain, hardware) can safely withstand in a given configuration. It varies with material, hardware, knot technique, and environmental factors. It should be considered alongside WLL but does not replace it for lifting operations.

Lashing capacity is how strong the securing lash system is in a given setup. Remember to compare it with the lifting device's rating and always consider the safer, lower value when planning a lift.

What exactly is Working Load Limit (WLL)?

WLL is the maximum load that a lifting device or component can safely handle under defined conditions, derived from standardized tests and safety factors. It serves as the controlling limit for safe lifting and rigging operations.

WLL is the safe maximum load a device can handle during use; it’s the primary limit to follow in rigging.

Can lashing capacity exceed WLL, and should I rely on that?

Yes, lashing capacity can exceed WLL in some configurations, but WLL remains the controlling limit for safety. Do not rely on lash capacity alone if the WLL is lower for any component or connection in the system.

Sometimes lash capacity is higher, but WLL governs safe loads. Always follow the lower rating.

How do I verify WLL in the field?

Check the component markings for WLL, verify the configuration matches the rated setup, and review manufacturer documentation. Perform regular inspections and document results to maintain compliance.

Look for the WLL marking, confirm the setup matches the rating, and log inspections.

What standards govern lashings and rigging?

Standards vary by region but commonly include OSHA guidance and ISO/EN standards for rigging and lifting. Always reference the supplier’s ratings and local regulations to ensure compliance.

Rigging standards come from OSHA and ISO/EN families; follow local rules and manufacturer specs.

When should I consult an engineer for lashings and WLL?

Consult an engineer when load conditions are uncertain, configurations are unusual, or the duty cycle is dynamic. Complex load paths or critical lifts benefit from expert review to ensure safe margins.

Call an engineer if loads are unclear or configurations are nonstandard.

Top Takeaways

- Define WLL as the primary safe-load limit for lifts

- Assess entire lash configuration to determine effective capacity

- Document ratings, conditions, and inspection history

- Use a conservative, standards-based approach to rigging

- Consult standards and experienced engineers for complex cases