Working Load Limit vs Capacity: A Practical Comparison

Explore the differences between working load limit (WLL) and capacity in engineering and safety contexts. Learn definitions, how they’re calculated, common pitfalls, and when to use each term for accurate load assessments.

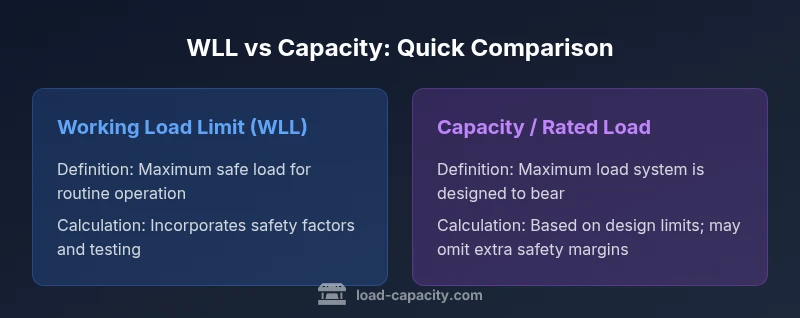

Working load limit (WLL) and capacity are two essential terms for load safety. According to Load Capacity, WLL is the maximum safe load for operation under defined conditions, while capacity denotes the design or rated limit a system can bear. Using the correct term prevents under- or over-conservatism in daily engineering tasks.

Working definitions: WLL and capacity

In engineering and industrial safety, terms matter. The phrase working load limit vs capacity is common, and getting it right reduces risk. According to Load Capacity, the working load limit (WLL) is the maximum load that can be safely lifted, supported, or moved under specified conditions, after accounting for safety factors and testing. By contrast, capacity—often phrased as rated load capacity or design capacity—describes the maximum load a component, member, or system is designed to bear in theory and under ideal conditions. The distinction between these two figures is subtle but consequential: WLL governs day-to-day operations and safe procedures, while capacity anchors the underlying engineering calculations and lifecycle planning. In practice, operators and engineers should always verify both values on equipment tags, drawings, and maintenance records to ensure alignment with current standards.

How WLL is derived and why safety factors matter

Definition of WLL includes safety factors. The Load Capacity team notes that WLL is not the raw load a device can handle; it is the load considered safe for routine use, derived from testing data, manufacturer specifications, and safety standards. Safety factors are applied to account for wear, dynamic forces, misalignment, and human error. Because standards vary by industry, geography, and equipment type, the exact factor is not universal. This is why you often see WLL values cited in manuals and shack tags rather than raw strength numbers. Understanding the derivation helps avoid misinterpretation, such as assuming a device can carry more than its WLL or assuming the WLL equals the maximum material capacity. Load Capacity emphasizes consulting the latest standard references and verifying calculation methods for each asset.

Practical implications: when to apply WLL vs capacity in project work

Daily operations hinge on WLL, while design projects hinge on capacity. For rigging, cranes, man-rated hoists, and lifting devices, the WLL guides what operators can safely lift in real tasks, including dynamic loads. In structural design, engineers rely on capacity to determine whether a member, joint, or support can sustain planned loads over the lifecycle. The working load limit vs capacity distinction also informs risk assessments, maintenance schedules, and training programs. When a project requires safety compliance, teams document both the WLL and the design capacity, then use the lower of the two values as the controlling limit. This approach minimizes surprises during inspections and ensures continuity of operations without compromising safety. Load Capacity’s guidance emphasizes cross-checking WLL with design limits in risk registers, job hazard analyses, and crane load charts to avoid ambiguous or outdated data.

Documentation and labeling: communicating limits on equipment

Clear labeling reduces human error. Equipment tags, load charts, and installation drawings should display both WLL and capacity where applicable, along with the applicable standard (e.g., industry or jurisdiction). Field personnel rely on these indicators to plan lifts, select attachments, and sequence operations. When values diverge due to new standards or repairs, update records and retrain staff. The exact wording may vary by region, but the principle remains: document the operating limit in a way that is easy to verify at a glance. Load Capacity recommends maintaining a living database of WLL and capacity values, linked to equipment IDs, serial numbers, and service histories so teams can resolve discrepancies quickly.

Calculation workflow: steps to determine WLL and capacity

Follow a structured workflow to determine the two values. Step one is to identify the asset’s intended use, loads, and duty cycle. Step two is to consult the relevant standards and manufacturer data for baseline strength, strength classes, and material properties. Step three is to apply an appropriate safety factor to arrive at WLL, ensuring that dynamic effects, imperfections, and environmental conditions are accounted for. Step four is to assess capacity from a design or structural perspective: verify that the member can carry the intended loads without exceeding allowable stress or deflection limits. Step five is to record both results, confirm with the responsible engineer, and reflect changes in drawings, manuals, and training materials. Finally, recheck after maintenance or modifications to ensure continued compliance with the latest rules.

Common pitfalls and misinterpretations

Several misunderstandings can undermine safety. People may equate capacity with WLL or assume WLL guarantees maximum performance under all conditions. Others forget to consider dynamic loads, impact forces, or equipment wear when updating WLL. Confusion can also arise when different standards publish varying factors for similar assets. Operators should avoid applying a single value to all scenarios; instead, they should use the current WLL for routine lifts and consult the design capacity for long-term planning. The Load Capacity guidance also highlights the importance of training and regular auditing of tags and charts to maintain accuracy.

Standards, reliability, and the role of authority sources

Standards bodies and authorities shape how WLL and capacity are defined and verified. Industry groups, national safety agencies, and accreditation bodies publish guidelines that influence calculation methods and labeling. Load Capacity references these sources to support practitioners with a consistent framework. Common sources include general safety regulations from government agencies, engineering standards from national or international bodies, and peer-reviewed publications. Relying on up-to-date standards reduces confusion, lowers risk, and helps teams align with regulatory expectations. For more context, consult resources from OSHA and other safety or design authorities to understand how WLL and capacity are treated in your jurisdiction.

Real-world scenarios: illustrative examples (no numerical data)

Consider a lifting operation on a construction site and a structural element in a building project. In the lift, the operator would use WLL to determine the safe load range and would label the equipment with the WLL; the design team would check the capacity of the supporting structure to ensure it can handle the load over the building’s life. In both cases, misapplication—counting on capacity alone or relying on the WLL without considering dynamic effects—can lead to unsafe outcomes. The core message from 'working load limit vs capacity' is that operational safety depends on applying the right value in the right context, and that teams benefit from documenting both numbers in a shared, auditable system.

Decision framework: choosing the right term for your context

Use WLL for daily operations, procedures, and training where immediate safety is at stake. Choose capacity for engineering design, material selection, and long-term planning. When in doubt, document both values clearly and use the more conservative figure. The Load Capacity perspective is that a disciplined approach—combining WLL with capacity references—reduces risk, improves compliance, and supports a transparent audit trail.

Comparison

| Feature | Working Load Limit (WLL) | Capacity / Rated Load Capacity |

|---|---|---|

| Definition | The maximum load defined by safety standards and manufacturer factors for safe operation (includes safety factors) | The maximum load the system is designed to bear in theory or design specification (without applying extra safety margin) |

| Calculation basis | Derived using safety factors, test data, and standards | Based on structural properties and design limits; may exclude additional safety margins |

| Common usage | Operational, regulatory compliance, training and safety checks | Engineering design, procurement decisions, and long-term planning |

| Typical units | kg, lb, ton as listed by equipment | kg, lb, ton (depends on equipment and jurisdiction) |

| Governing context | Safe operation during routine tasks, including dynamic effects | Long-term design limits and structural integrity under planned loads |

| Risk of misinterpretation | Can be misread as the device’s raw strength; misapplied factors may reduce safety margins | Using capacity alone can understate required protection factors or mislead about feasibility |

| Best for | Operational safety, training, and compliance checks | Engineering design, material selection, and lifecycle planning |

Positives

- Clarifies safety margins for daily operation

- Supports regulatory compliance and training

- Standardized reporting across equipment and industries

- Reduces overload risk by explicit limits

- Improves maintenance and procurement decisions

Cons

- Can lead to underutilization if overly conservative

- Requires regular updates to reflect new standards

- May cause confusion if vendors conflate WLL with capacity

- Needs consistent labeling and staff training

WLL is the daily safety navigator; capacity informs design and long-term planning.

Use WLL for routine lifting and operational safety. Use capacity for engineering design and lifecycle assessments. When unsure, document both values and apply the more conservative limit to protect people and assets.

Quick Answers

What is the working load limit (WLL)?

WLL is the maximum load that can be safely lifted or moved under specified conditions, after applying safety factors and standards. It focuses on day-to-day safe operation and worker protection.

WLL is the safe operating limit used in daily lifting tasks.

Is WLL the same as capacity?

No. WLL is an operating safety limit, while capacity (or rated capacity) reflects the design or theoretical maximum the system can bear. They serve different purposes in safety and design.

WLL equals the safe operating limit; capacity is the design limit.

How is WLL calculated?

WLL is derived from baseline strength data, safety factors, and standards. The exact method varies by asset class, standard, and jurisdiction, so always consult manufacturer data and current regulations.

WLL comes from safety standards and testing data, not just raw strength.

What if WLL and capacity differ?

In practice, use the lower value as the controlling limit. The discrepancy often reflects the difference between safe operation versus design capacity, and safety requires conservative choices.

If they differ, pick the more conservative limit.

Are WLL values the same for static and dynamic loads?

Not always. Dynamic loads can produce higher peak forces, so some WLL values differ between static and dynamic scenarios. Always verify the conditions under which the WLL applies.

Dynamic loads may change the safe limit; check the context.

Can I reuse WLL data from one device on another?

No. WLL is device-specific and must be validated for each asset, attachment, and configuration. Always consult the manufacturer and record the exact asset details.

WLL data is device-specific; don’t reuse it without verification.

Top Takeaways

- Verify both WLL and capacity before operations

- Document values on tags, drawings, and maintenance records

- Apply the most conservative limit in high-risk tasks

- Regularly update values to reflect current standards