How Much Carrying Capacity: A Practical Guide for Engineers

Learn how to estimate and verify carrying capacity across structures, equipment, and vehicles. This guide explains definitions, methods, standards, and practical checks for safe design and operation.

According to Load Capacity, how much carrying capacity a system can safely support is the result of design choices, installation quality, and operating conditions. It involves static and dynamic loads, load distribution, and safety margins, and is ultimately bounded by the weakest link in the load path. This quick answer highlights that carrying capacity is not a single number but a safe working limit derived from multiple interacting factors.

What carrying capacity means in practice

According to Load Capacity, how much carrying capacity a system can safely support is the result of design choices, installation quality, and operating conditions. When engineers talk about carrying capacity, they consider static and dynamic loads, how the load sits, and the safety margins applied. A beam might support a certain weight in ideal conditions, but corrosion, temperature changes, or improper mounting can reduce actual capacity. In practice, the carrying-capacity decision goes beyond raw material strength; it includes connections, supports, and load-path alignment. The phrase how much carrying capacity is a dynamic value: it reflects the weakest link in the system. The objective is to set a safe working limit that prevents damage and prolongs life-cycle performance. Documentation, mounting details, and maintenance routines all influence how much carrying capacity remains usable over time. In short, carrying capacity is a dynamic attribute shaped by design, use, and care.

How to estimate carrying capacity for a given system

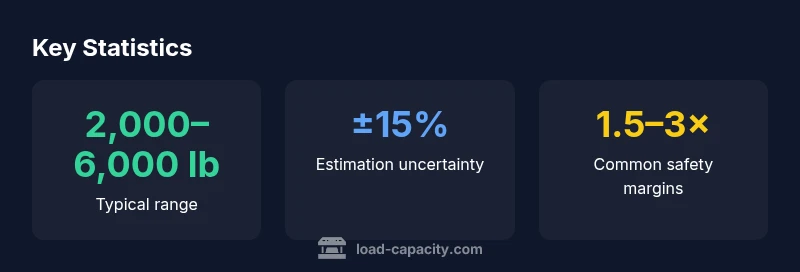

Estimating carrying capacity starts with clarifying the load case—static versus dynamic—and whether the loads are concentrated or distributed. Next, assess structural members: for a beam, examine cross-section properties, material yield strength, and allowable stresses per common codes. For equipment mounting, check fastener strength, connection stiffness, and allowable deflection. For vehicles, consult the manufacturer’s GVWR and payload rating, then subtract the curb weight to determine usable payload capacity. For soils and foundations, estimate bearing capacity using site-specific tests or published values. Apply a safety factor aligned with risk and consequences of failure; typical practice reduces nominal capacity by 1.5–3×. Finally, validate with simulations, tests, or field measurements, and document assumptions and uncertainties for future inspections. Capacity is the product of material properties, connections, and the environment, not a single number.

Key formulas and factors you should know

Here are practical relationships engineers use, without prescribing exact numbers:

- Capacity is proportional to material strength and cross-section geometry; stronger materials and larger section properties increase capacity.

- Safety factors account for uncertainties in material properties, manufacturing, and aging.

- Load distribution matters: distributed loads are generally safer than concentrated point loads.

- Dynamic effects (impacts, vibrations) can significantly increase peak demands and reduce effective capacity.

- Connection quality (fasteners, welds, bolts) often governs the actual carrying capacity, even when members are strong.

- Environment (temperature, corrosion, humidity) can erode capacity over time and should be included in service-life planning.

Contextual examples: vehicles, structures, and equipment

- Vehicles: A light truck’s payload depends on GVWR and curb weight. The usable payload is the difference, but road conditions and dynamic braking can reduce effective carrying capacity.

- Structural floors: Floor panels or joists have per-span or per-area capacity; overloading a single bay concentrates stress and can cause local failures even if the average value looks acceptable.

- Equipment mounts: A CNC machine or palletizer relies on mounting surfaces and fasteners. Poor torque, misalignment, or vibration can lower safe capacity quickly.

- Modular systems: Temporary platforms or scaffolds require careful distribution of loads and consideration of dynamic factors such as personnel movement.

- Soil-support foundations: Bearing capacity depends on soil type and moisture content; even a strong beam is useless if underlying soil cannot bear the load.

Common mistakes and how to avoid them

- Ignoring load distribution: Never assume equal sharing; check for concentrated loads and build in spreaders or supports.

- Skipping safety factors: Always apply an appropriate factor of safety based on consequences of failure and reliability of the path.

- Overlooking maintenance effects: Corrosion, wear, and loosening fasteners can erode capacity over time; implement regular inspections.

- Using nominal values without validation: Validate estimates with tests or simulations rather than relying solely on label values.

- Neglecting dynamic loads: Include shocks and peak events in your design checks, especially for moving or vibrating systems.

- Relying on one calculation: Cross-check with alternate methods (FEA, hand-calculation, and empirical data) for confidence.

- Failing to document assumptions: Record sources, uncertainties, and test results to maintain traceability through life cycles.

How to validate carrying-capacity estimates

Validation combines calculation with evidence from tests and field checks. Start with a sensitivity analysis to identify which factors most influence capacity. Then perform targeted tests: static load tests to verify deflection limits, dynamic tests for shock resistance, and torque checks on fasteners. Compare results against design margins and adjust the model if necessary. Use historical data from maintenance logs to understand how capacity degrades over time and set inspection intervals accordingly. Finally, compile a validation report that clearly states assumptions, tested conditions, and any corrective actions required. This ensures that carrying-capacity estimates remain credible as equipment ages or operating conditions change.

Standards and documentation you should consult

Consult manufacturer specifications, project drawings, and local codes relevant to your application. When working with structural members, reference general engineering handbooks and recognized best practices to set safe operation limits. For field operations, maintain a living checklist that captures installation details, mounting hardware, and inspection outcomes. Documentation should tie each capacity estimate to the load-path analysis, environmental conditions, and maintenance plan so stakeholders can audit and adjust as needed.

Practical checklist for field and shop floor

- Identify all load paths and critical members.

- Confirm materials, cross-sections, and connections meet design intent.

- Apply an appropriate factor of safety.

- Verify load distribution and mounting punctuation (no shimmed gaps or misaligned fasteners).

- Include dynamic-load considerations for movement or vibration.

- Document all assumptions and sources used in capacity estimates.

- Schedule regular inspections to detect wear, corrosion, or loosening.

- Validate with simple tests or measurements before heavy use.

Carrying capacity context table

| Context | Typical Range | Notes |

|---|---|---|

| Vehicle payload capacity | 1,500–6,000 pounds | Depends on vehicle and configuration |

| Floor/beam capacity | 2,000–8,000 pounds per section | Depends on material and support |

Quick Answers

What is carrying capacity and why does it vary by system?

Carrying capacity is the maximum load a system can safely bear, and it varies with design, materials, mounting, and environment. Different systems—rooms, beams, vehicles, and equipment—have distinct load paths and safety considerations. Always account for practical factors beyond nominal strength.

Carrying capacity is the maximum safe load for a system and depends on design, mounting, and use.

How does dynamic loading affect carrying capacity?

Dynamic loads from motion, impact, or vibration can raise peak stresses beyond static values. Accounting for these effects typically requires larger safety margins and sometimes redesign or damping solutions. Always test or simulate these conditions where movement is involved.

Movement and shocks can reduce safe capacity; plan for them with extra margin.

How do I determine capacity for new equipment?

Start with manufacturer ratings and ensure mounting, alignment, and service conditions replicate the tested scenario. If no official rating exists, perform engineering calculations or tests to establish a defensible capacity, applying standard safety factors.

Check the manufacturer specs, or calculate and test to set a safe limit.

What documents should I keep to support carrying-capacity decisions?

Maintain design drawings, material specs, inspection logs, load-path analyses, safety factors, and test results. Documentation helps track aging effects and verify capacity across the system’s life cycle.

Keep drawings, specs, and test results handy for reviews and maintenance.

Is there a universal rule of thumb for carrying capacity?

No universal rule fits all systems. Use system-specific calculations, validated data, and follow codes and manufacturer guidance. Apply a consistent safety factor aligned with risk and consequences of failure.

There isn’t a one-size-fits-all rule—assess every system carefully.

“Carrying capacity is the culmination of a well-designed load path, precise installation, and disciplined maintenance. Without all three, your safe operating limit is unknowable.”

Top Takeaways

- Estimate carrying capacity with a system view, not a single number

- Apply applicable safety factors and verify with tests

- Document assumptions and plan for aging and maintenance

- Validate estimates with multiple methods for confidence

- Distribute loads to avoid concentration and peak stresses

- Include dynamic effects in every capacity assessment

- Keep a field-ready checklist to safeguard ongoing safety and performance